Method for preparing different-electrode composite materials of carbon plate/manganese dioxide nanometer sheet and application thereof

A manganese dioxide and composite material technology, applied in electrical components, electrolytic capacitors, capacitors and other directions, can solve the problems of difficult assembly, high cost of organic electrolyte, poor conductivity, etc., to improve conductivity, suitable for large-scale production, Good specific energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 0.2 g of mesoporous carbon nanosheets were ultrasonically dispersed into 100 ml of 2M sulfuric acid solution, heated to 70° C. and stirred for 3 hours, and then filtered with suction to obtain acidified mesoporous carbon nanosheets. Add 0.05g of acidified mesoporous carbon nanosheets to 25ml of 0.5M sulfuric acid solution, ultrasonically disperse it for 15 minutes, raise the temperature to 50°C, add 0.1g of KMnO 4 , stirred and reacted for 5 minutes, and the product was washed and dried to obtain a hierarchical composite material of carbon sheet / manganese dioxide nanosheet.

Embodiment 2

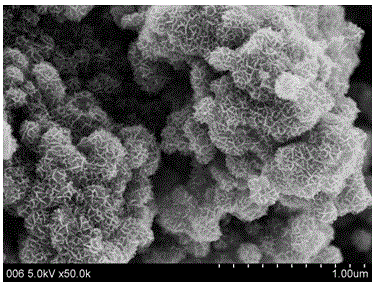

[0030] 0.2 g of mesoporous carbon nanosheets were ultrasonically dispersed into 100 ml of 2M sulfuric acid solution, heated to 70° C. and stirred for 3 hours, and then filtered with suction to obtain acidified mesoporous carbon nanosheets. Add 0.05g of acidified mesoporous carbon nanosheets to 25ml of 0.5M sulfuric acid solution, ultrasonically disperse it for 15 minutes, raise the temperature to 50°C, add 0.1g of KMnO 4 , stirred and reacted for 10 minutes, and the product was washed and dried to obtain a hierarchical composite material of carbon sheet / manganese dioxide nanosheet. Electron microscope photographs of the product figure 1 shown.

Embodiment 3

[0031] Example 3 Electrochemical characterization of carbon sheet / manganese dioxide nanosheet composite

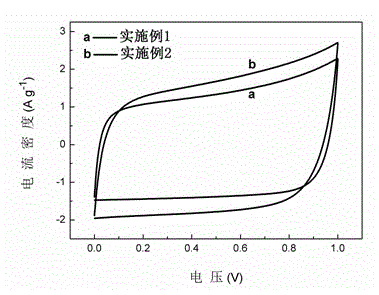

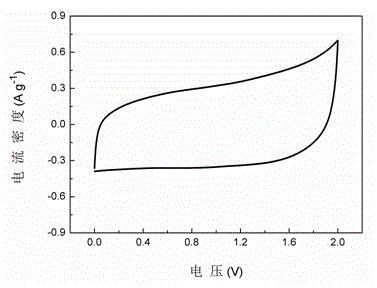

[0032] Mix the composite material prepared in Examples 1 and 2, conductive carbon black and polytetrafluoroethylene emulsion in a mass ratio of 85:10:5, add a small amount of absolute ethanol, and press it into a thin sheet with a thickness of about 1mm. Punched into a disc with a diameter of 11mm, and then compacted under a pressure of 10MPa. Two electrodes of equal mass are used as the positive and negative electrodes of the capacitor, a diaphragm is sandwiched between them, and a 1 M sodium sulfate solution is used as the electrolyte to assemble a simulated symmetrical supercapacitor. The composite material is used as the positive electrode material, and the carbon sheet is used as the negative electrode material to assemble an asymmetric supercapacitor. The assembled supercapacitor was subjected to cyclic voltammetry and constant current charge and discharge tests at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com