Novel heat exchanger provided with micro channel heat exchange plate

A technology of heat exchange plates and microchannels, which is applied to the types of heat exchangers, indirect heat exchangers, and heat exchange equipment. And the effect of simple structure, good heat exchange effect and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

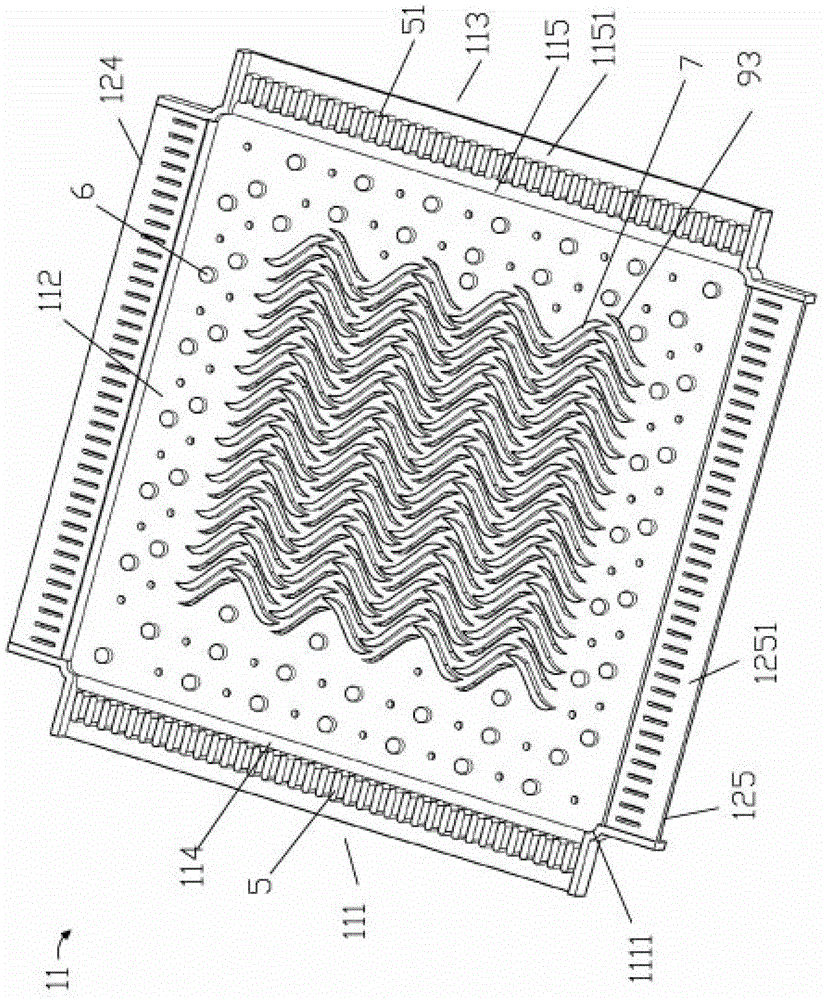

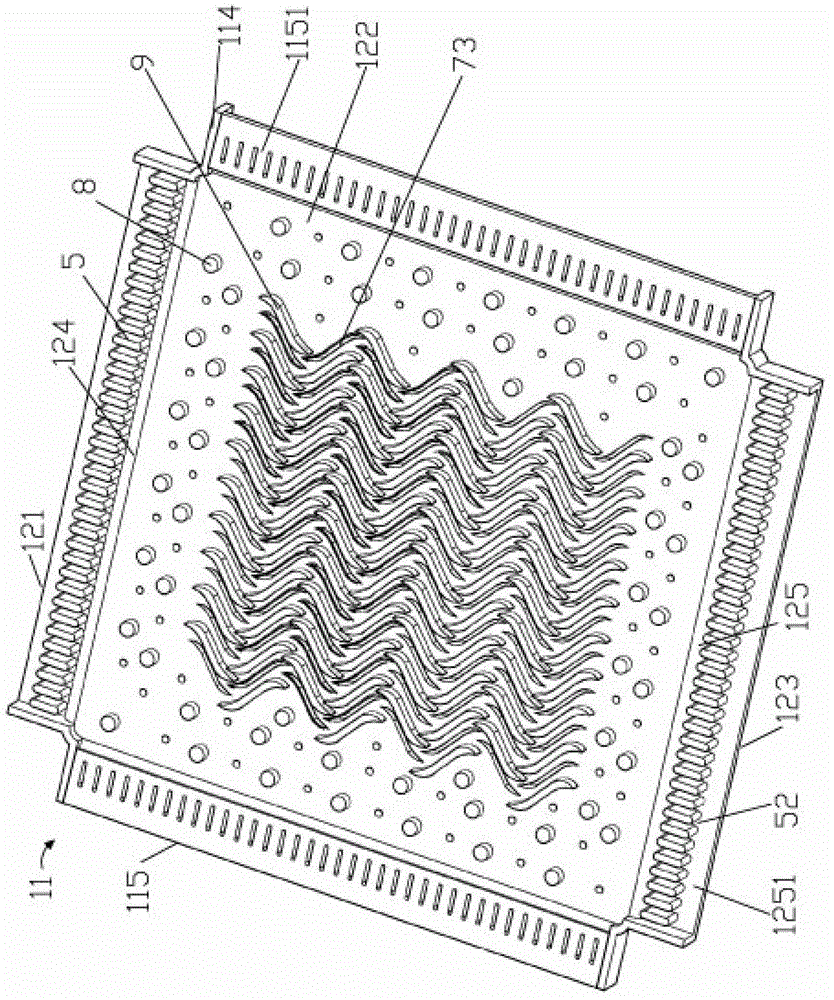

[0038] Example: see Figure 1 to Figure 10 As shown, a new heat exchanger with a microchannel heat exchange plate includes a heat exchanger shell 100 and a heat exchange device. The heat exchanger shell 100 is provided with a heat exchange medium inlet 1, a heat exchange medium outlet 2, Refrigerant inlet 3 and refrigerant outlet 4, the heat exchange device consists of a partition 12 between two adjacent microchannel heat exchange plates 11 up and down, multiple microchannel heat exchange plates 11 and multiple partitions 12 The method is stacked at intervals and connected by atomic diffusion welding. The front and back sides of the micro-channel heat exchange plate 11 are punched and formed with a plurality of interwoven mesh grooves, and the left and right sides of the micro-channel heat exchange plate 11 are downward. Bending to form a left end folded plate 114 and a right end folded plate 115, the upper and lower sides of the microchannel heat exchange plate 11 are bent up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com