Electric angular-travel actuator

An electric actuator, angular stroke technology, applied in the direction of engine components, mechanical equipment, valve details, etc., can solve the problems of insufficient function, large volume, unfavorable installation, debugging and maintenance of valve users, and achieve simple structure and small volume. , beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

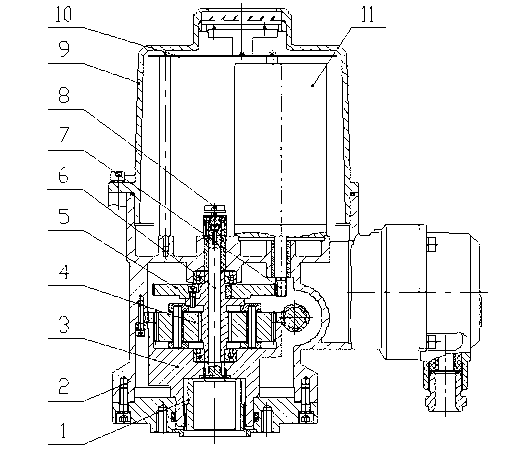

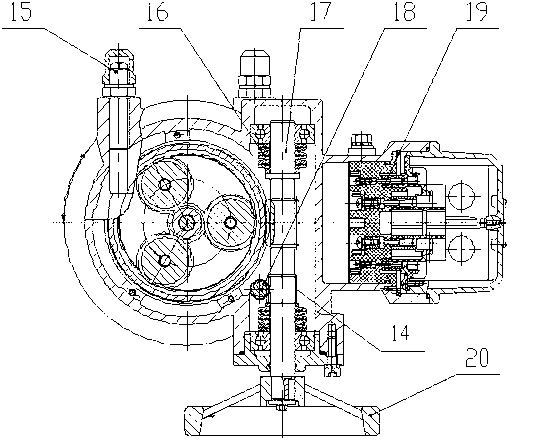

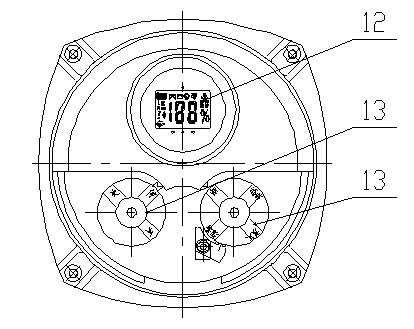

[0020] As shown in the figure, the angular stroke electric actuator of the present invention includes a box body 2, a box cover 9 is fixedly connected above the box body 2, a brake motor 11 is arranged below the box cover 9, and the brake motor 11 The motor pinion shaft 7 drives the gear 5 to rotate, the gear 5 drives the planetary reduction mechanism to move 4, the planetary reduction mechanism 4 drives the output shaft gear 3 to rotate, and the output shaft gear 3, the gear 5 and the planetary reduction mechanism 4 are all installed On the long axis 6, a spline sleeve 1 is installed in the shaft-out gear 3, and a striker pin 15 is arranged at a position corresponding to the shaft-out gear 3 on the side wall of the box body 2. 3 is provided with two planes adapted to the striker pin 15, the worm 17 is located on the peripheral si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com