Fuel supply device

A fuel supply device and fuel technology, which are applied to liquid fuel feeders, liquid fuel engines, components of pumping devices for elastic fluids, etc., can solve problems such as increased pressure loss, increased pressure loss, and steam generation. Achieve stable pump discharge, suppress suction, and control fuel pressure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

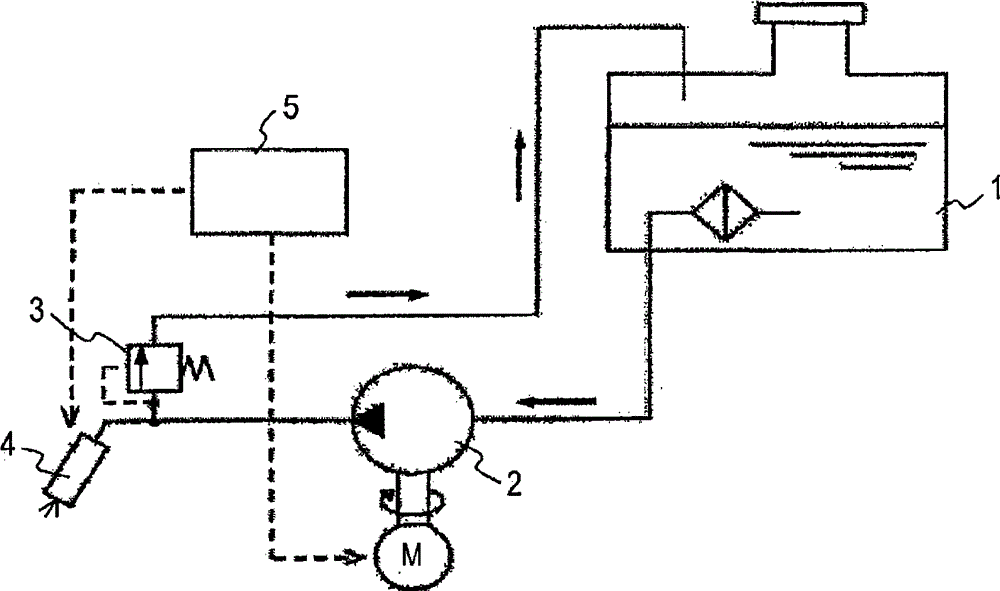

[0062] figure 1 It is a configuration diagram of a fuel system using the fuel supply device of the present invention.

[0063] The fuel supply device 2 is driven based on a drive signal from the control unit 5, and the fuel supply device 2 sucks fuel from the fuel tank 1 through a filter and discharges it.

[0064] The discharged fuel is regulated to a predetermined pressure by the pressure regulator 3 and supplied to the fuel injection device 4 via a high-pressure fuel pipe.

[0065] The fuel injection device 4 controls the injection timing and injection amount based on the engine speed and load, etc., according to a drive signal from the control unit 5, and injects fuel into the intake pipe.

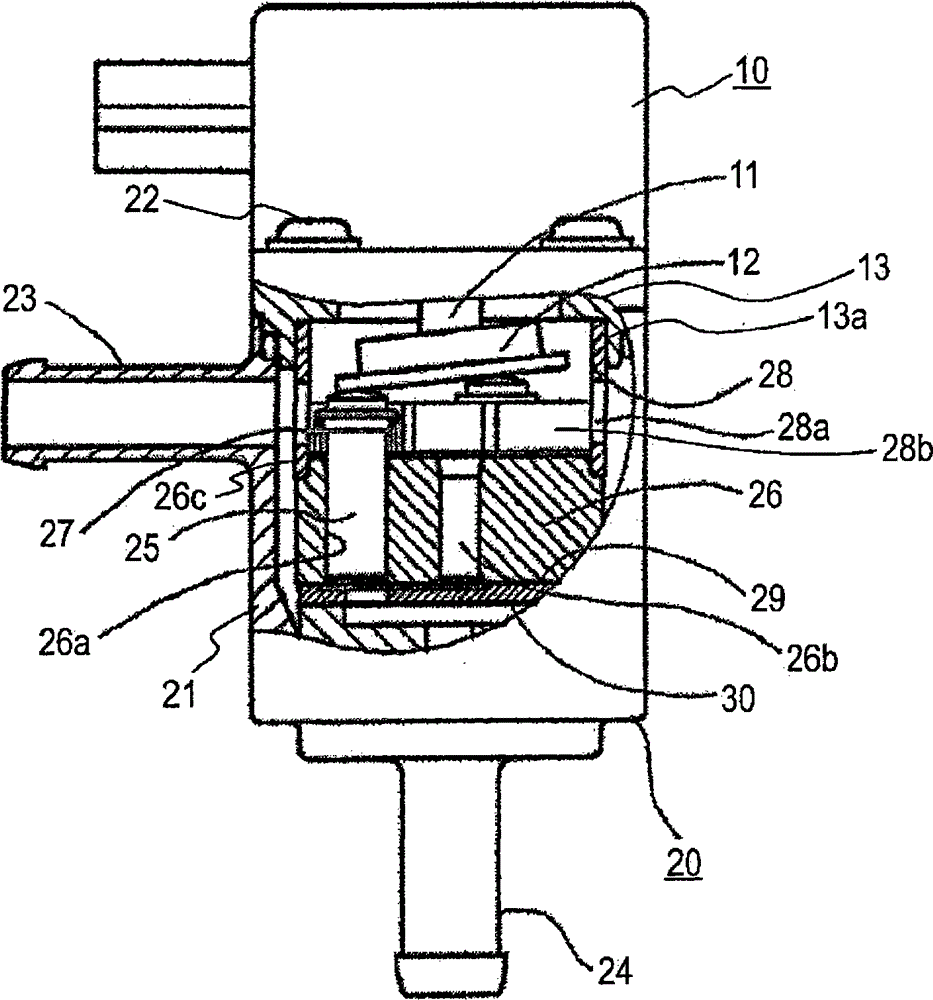

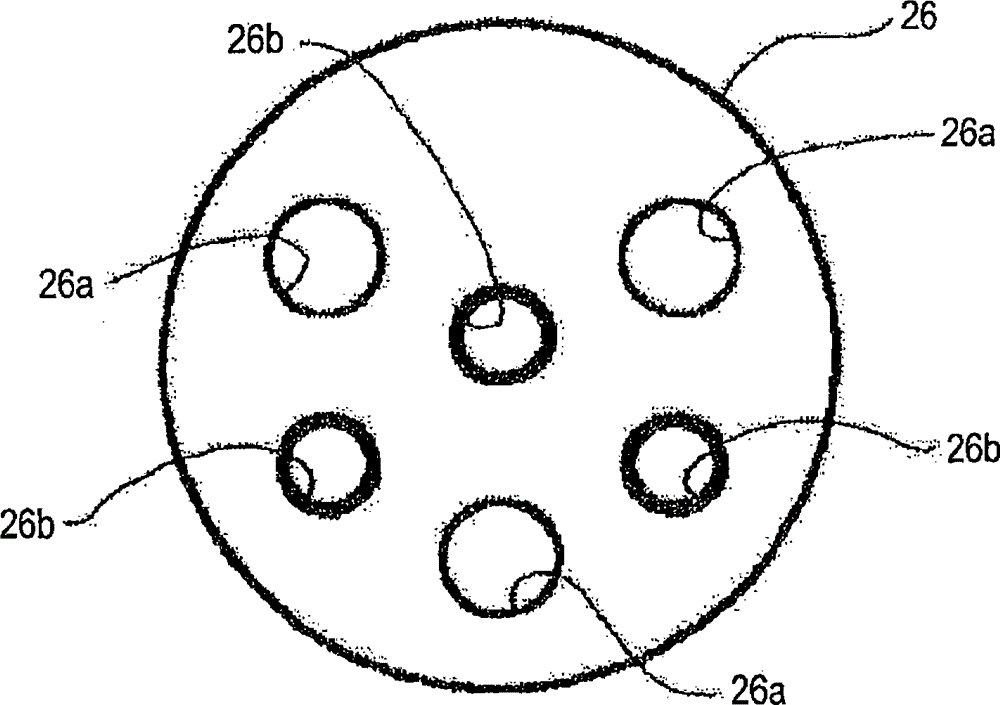

[0066] figure 2 It is a block diagram showing the fuel supply device 2 according to Embodiment 1 of the present invention. image 3 is a plan view of the cylinder of Embodiment 1, Figure 4 It is a side view showing the liner and cylinder of Embodiment 1, Figure 5 yes Figure 4...

Embodiment approach 2

[0091] Figure 8 It is a plan view showing the liner and the cylinder according to Embodiment 2 of the present invention, Figure 9 yes Figure 8 C-C section view. Such as Figure 8 , Figure 9 As shown, the bushing 28 of the second embodiment has a partition wall 28d formed to surround the inlet of the suction port 26b in a cylindrical shape.

[0092] According to the second embodiment, similar to the first embodiment, the fuel near the suction port 26b is less affected by the swirling flow, and the vapor generated by the reciprocating operation of the piston 25 can be suppressed from being sucked into the suction port 26b.

Embodiment approach 3

[0094] Figure 10 It is a plan view showing the liner and the cylinder according to Embodiment 3 of the present invention, Figure 11 yes Figure 10 D-D cutaway view, Figure 12 It is a sectional view showing the positional relationship between the bush and the suction joint in the third embodiment.

[0095] The bushing 28 according to Embodiment 3 is provided with a partition wall 28e surrounding the outer periphery of the piston 25, and a recessed fuel passage 28f connected to the plurality of suction ports 26b.

[0096] Additionally, if Figure 12 As shown, one end of the fuel passage 28f opens at a position substantially opposite to the suction joint 23 formed in the casing 21 .

[0097] According to the third embodiment, as in the first embodiment, the fuel located near the suction port 26b is less likely to be affected by the swirling flow, and the piston 25 is fitted and inserted into the hole 28g formed in the partition wall 28e of the bushing 28, so that It is su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com