Vertical regenerated cotton device and production technology

A production process and technology for regenerated cotton, applied in the field of regenerated cotton production, can solve the problems of inability to meet the production requirements of regenerated cotton, poor hygroscopicity, and many raw materials, and achieve the effects of simple structure, low consumption of raw materials, and strong air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

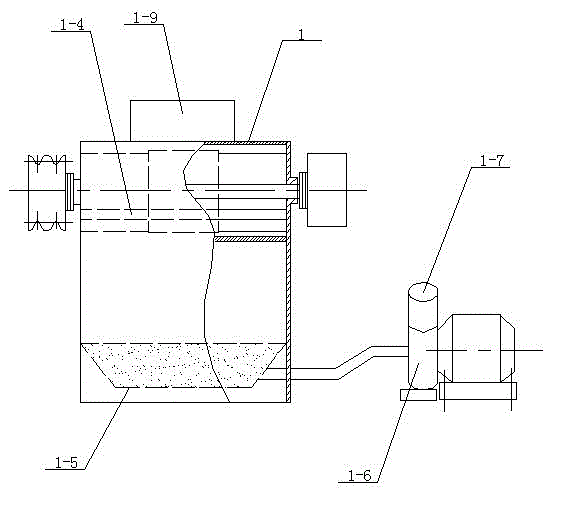

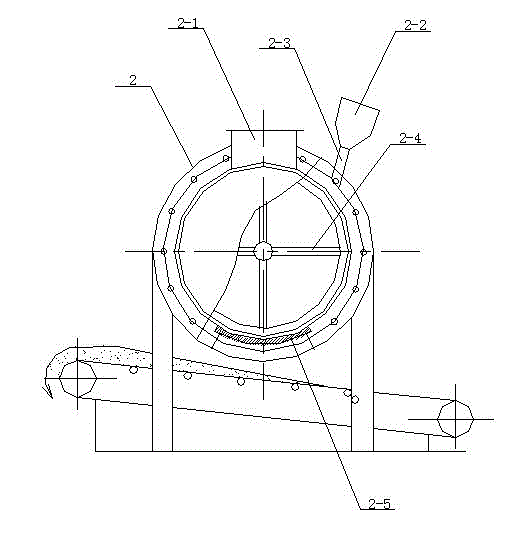

[0016] refer to Figure 1-Figure 6 , the present embodiment adopts the following technical solutions: its production process is: a, select the waste polyurethane foam that needs to be crushed according to the production requirements, select hard skin, impurities, etc., and distinguish the color and density of waste polyurethane foam, Change the crushing filter screen according to the thickness requirements; b, put the waste polyurethane foam into the powerful pulverizer 1 for crushing, so that the waste polyurethane foam scraps become irregular granular with uniform size; C, put the waste polyurethane foam scraps Add stannous octoate, polyurethane and polypropylene glycol to fully mix; d, input the mixed waste polyurethane foam scraps into the foam machine 2 and stir continuously, first add an appropriate amount of toner and stir evenly, and then spray Add stannous octoate, polyurethane and polypropylene glycol raw materials to stir the mixture evenly and foam; e, put the wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com