High-temperature variable-carbon potential quick carburizing treatment process for gear parts

A carburizing treatment and variable carbon potential technology, applied in the field of heat treatment, can solve the problems of long process time and low efficiency, and achieve the effect of shortening process time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

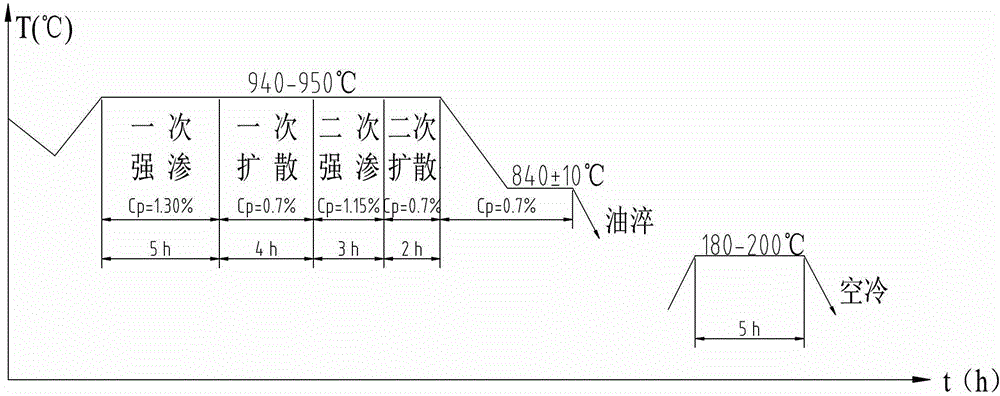

[0022] Such as figure 1 As shown, the first embodiment of the high-temperature variable carbon potential rapid carburizing process for gear parts of the present invention, the steps are as follows:

[0023] (1) One-time infiltration: first, carburize the parts in the carburizing furnace, maintain the furnace temperature in the range of 940-950°C, hold the time for 300 minutes, and keep the carbon potential in the mesh belt furnace within 1.30CP;

[0024] (2) Primary diffusion: Carburize the parts in the carburizing furnace, maintain the furnace temperature in the range of 940-950°C, keep the temperature for 240 minutes, and the carbon potential in the mesh belt furnace is 0.7% CP;

[0025] (3) Secondary strong infiltration: keep the furnace temperature in the range of 940-950°C, keep warm for 180min, and the carbon potential in the mesh belt furnace is 1.20%CP;

[0026] (4) Secondary diffusion: keep the furnace temperature in the range of 940-950°C, keep it warm for 120min, a...

Embodiment 2

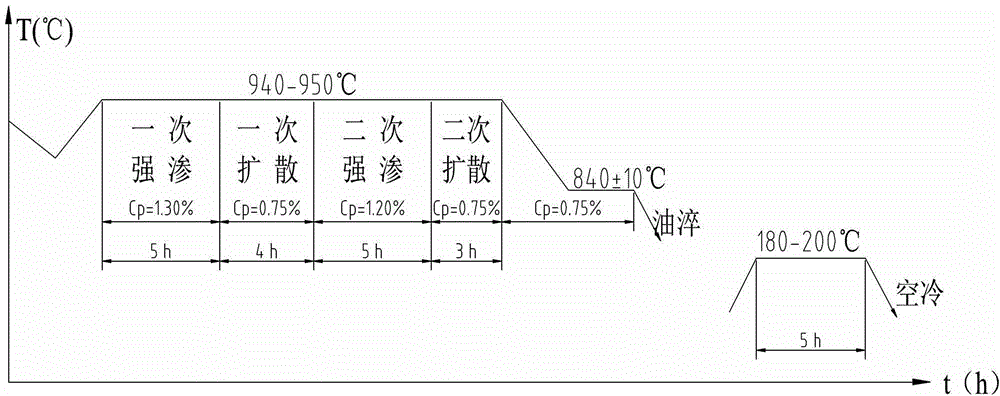

[0034] Such as figure 2 As shown, the second embodiment of the high-temperature variable carbon potential rapid carburizing process for gear parts of the present invention, the steps are as follows:

[0035] The difference from Embodiment 1 is that:

[0036] (1) One-time infiltration: first, carburize the parts in the carburizing furnace, maintain the furnace temperature in the range of 940-950°C, hold the temperature for 300 minutes, and keep the carbon potential in the mesh belt furnace within 1.30% CP;

[0037] (2) Primary diffusion: Carburize the parts in the carburizing furnace, maintain the furnace temperature in the range of 940-950°C, keep the temperature for 240 minutes, and the carbon potential in the mesh belt furnace is 0.75% CP;

[0038] (3) Secondary strong infiltration: keep the furnace temperature in the range of 940-950°C, keep it warm for 300min, and the carbon potential in the mesh belt furnace is 1.25%CP;

[0039] (4) Secondary diffusion: maintain the fu...

Embodiment 3

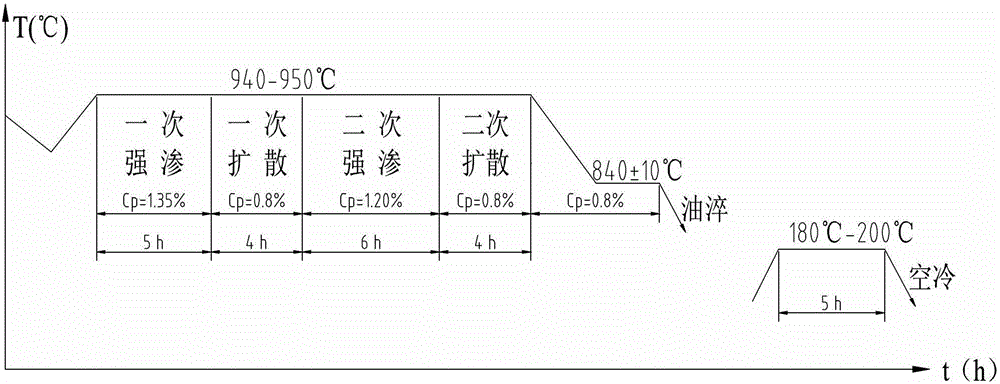

[0043] Such as image 3 As shown, the third embodiment of the high-temperature variable carbon potential rapid carburizing process for gear parts of the present invention, the steps are as follows:

[0044] The difference from Embodiment 1 is that:

[0045] (1) One-time infiltration: first, carburize the parts in the carburizing furnace, maintain the furnace temperature in the range of 940-950°C, hold the temperature for 300 minutes, and keep the carbon potential in the mesh belt furnace within 1.35% CP;

[0046] (2) Primary diffusion: Carburize the parts in the carburizing furnace, maintain the furnace temperature in the range of 940-950°C, keep the temperature for 240 minutes, and the carbon potential in the mesh belt furnace is 0.8% CP;

[0047] (3) Secondary strong infiltration: keep the furnace temperature in the range of 940-950°C, keep warm for 360min, and the carbon potential in the mesh belt furnace is 1.30%CP;

[0048] (4) Secondary diffusion: keep the furnace temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com