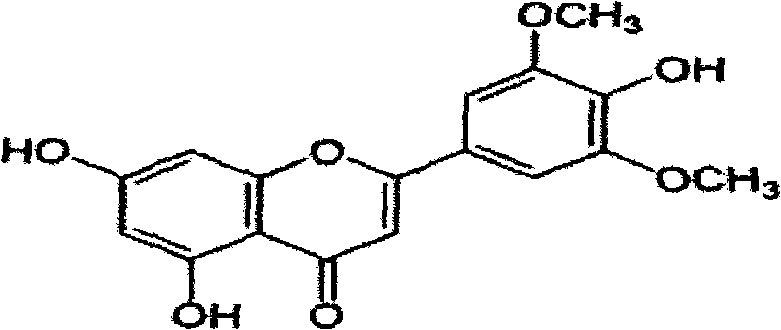

Method for extracting tricin from alfalfa

A technology of alfalfa and alfalfa, applied in the biological field, can solve the problems of cumbersome operation, serious sample loss, poor reproducibility, etc., and achieve the effect of solving serious pollution, large amount of preparation, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Dry and pulverize alfalfa grass, take 1kg and add 8 times the amount of 80% ethanol to reflux for extraction twice, concentrate the extract to no alcohol, add 200ml polyamide resin column for adsorption, take 5BV40% ethanol solution to elute impurities, and then use 70% ethanol solution Elution, TLC detection, collection of high-concentration fractions and concentration, the concentrated solution was extracted three times with an equal volume of ethyl acetate, and the ethyl acetate was recovered to obtain 8 g of crude product. Take n-hexane, ethyl acetate, methanol, and water and mix them according to 5:7:4:6. After standing and stratifying, take the upper phase and fill the high-speed countercurrent chromatography column, turn the host, adjust the speed to 700rpm, and pump into the lower phase for flow. Phase, after the dynamic equilibrium is established, the flow rate is adjusted to 3ml / min, and the crude product dissolved in the mobile phase is injected by the injecti...

Embodiment 2

[0018] Dry and pulverize alfalfa grass, take 1kg and add 5 times the amount of 60% ethanol to reflux and extract for 3 times, concentrate the extract to no alcohol, add 250ml polyamide resin column for adsorption, take 4BV50% ethanol solution to elute impurities, and then use 70% ethanol solution Elution, TLC detection, collection of high-concentration fractions and concentration, the concentrated solution was extracted three times with an equal volume of ethyl acetate, and the ethyl acetate was recovered to obtain 10 g of crude product. Take n-hexane, ethyl acetate, methanol, and water and mix them according to 4:5:3:4. After standing and stratifying, take the upper phase and fill the high-speed countercurrent chromatography column, turn the host, adjust the speed to 800rpm, and pump into the lower phase for flow. Phase, after the dynamic equilibrium is established, the flow rate is adjusted to 2ml / min. At the same time, the crude product dissolved in the mobile phase is injec...

Embodiment 3

[0020] Dry and pulverize alfalfa grass, take 1kg and add 7 times the amount of 70% ethanol to reflux for extraction twice, concentrate the extract to no alcohol, add 200ml polyamide resin column for adsorption, take 4BV50% ethanol solution to elute impurities, and then use 70% ethanol solution Elution, TLC detection, collection of high-concentration fractions and concentration, the concentrated solution was extracted three times with an equal volume of ethyl acetate, and the ethyl acetate was recovered to obtain 7 g of crude product. Mix n-hexane, ethyl acetate, methanol, and water at a ratio of 7:8:5:6, and after standing for stratification, take the upper phase and fill the high-speed countercurrent chromatography column, turn the host, adjust the speed to 700rpm, and pump into the lower phase for flow Phase, after the establishment of dynamic equilibrium, the flow rate was adjusted to 1ml / min, and the crude product dissolved in the mobile phase was injected by the injection ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com