Method for preparing propionic acid from ethyl acetate through carbonylation

A technology of ethyl acetate and carbonylation, which is applied to the preparation of carboxylic acid by carbon monoxide reaction, organic chemistry, etc., can solve the problem of low product selectivity and achieve the effect of improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preparing propionic acid by carbonylation of ethyl acetate comprises adding 2 mmol of rhodium acetate as a main catalyst, 0.5 mol of ethyl acetate, 0.1 mol of ethyl iodide, and 0.75 mol of water into a 250 ml reactor. The air in the kettle was replaced with carbon monoxide, the stirring speed was 600 rpm, the reaction temperature was kept at 180°C, the carbon monoxide constant pressure was 5.0 MPa, and the reaction was carried out for 5 hours. The conversion rate of ethyl acetate was 60.3%, and the selectivity of propionic acid was 85.3%.

Embodiment 2

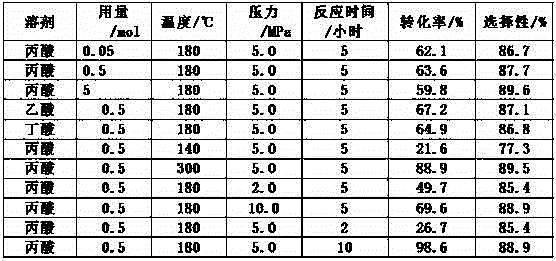

[0022] A method for preparing propionic acid by carbonylation of ethyl acetate. In a 250ml reactor, add 2mmol of rhodium acetate as the main catalyst, 0.5mol of ethyl acetate, a polar solvent, 0.1mol of ethyl iodide, and 0.75mol of water. Replace the air in the kettle with carbon monoxide, stir at a speed of 600 rpm, and react at a certain reaction temperature and a certain carbon monoxide pressure. The types of polar solvents, reaction conditions, and results are shown in Table 1.

[0023] Table 1

[0024]

Embodiment 3

[0026] In a 250ml reactor, add 2mmol of main catalyst, 0.5mol of ethyl acetate, 0.5mol of propionic acid, 0.05mol of iodide additive, 4mmol of ligand, 0.75mol of water and a certain amount of ethyl iodide. The air in the kettle was replaced with carbon monoxide, the reaction temperature was kept at 180° C., the carbon monoxide constant pressure was 5.0 MPa, and the stirring speed was 600 rpm. After 5 hours of reaction, the results are shown in Table 2.

[0027] main catalyst additive Ligand Iodoethane / mol Conversion rates / % Selective / % Rhodium acetate Hydroiodic acid Triphenylphosphine 0.1 70.8 97.3 Rhodium chloride Hydroiodic acid Triphenylphosphine 0.1 70.1 97.6 Rhodium dichlorotetracarbonyl Hydroiodic acid Triphenylphosphine 0.1 72.3 97.8 Rhodium acetate lithium iodide Triphenylphosphine 0.1 61.1 89.9 Rhodium acetate potassium iodide Triphenylphosphine 0.1 63.8 91.2 Rhodium acetate High tin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com