High-power illuminating device assembled by low-power LEDs (Light Emitting Diodes)

A lighting device and low-power technology, which is applied in the direction of lighting devices, lighting device components, lighting device cooling/heating devices, etc., can solve the problems of high cost, easy damage, too fast, etc., to ensure the design life and price Reasonable cost, overcome the effect of fast light decay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment, the present invention will be further described.

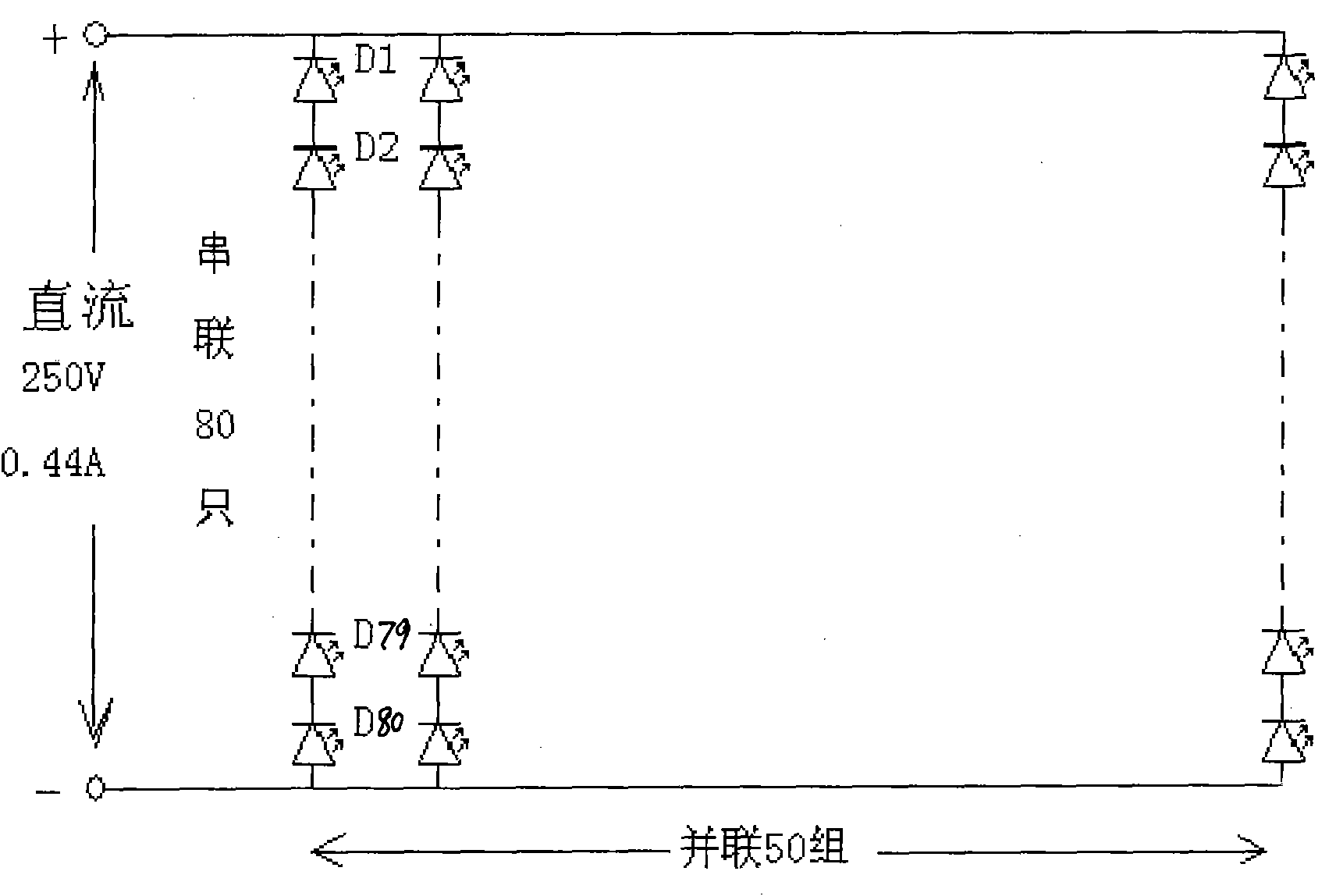

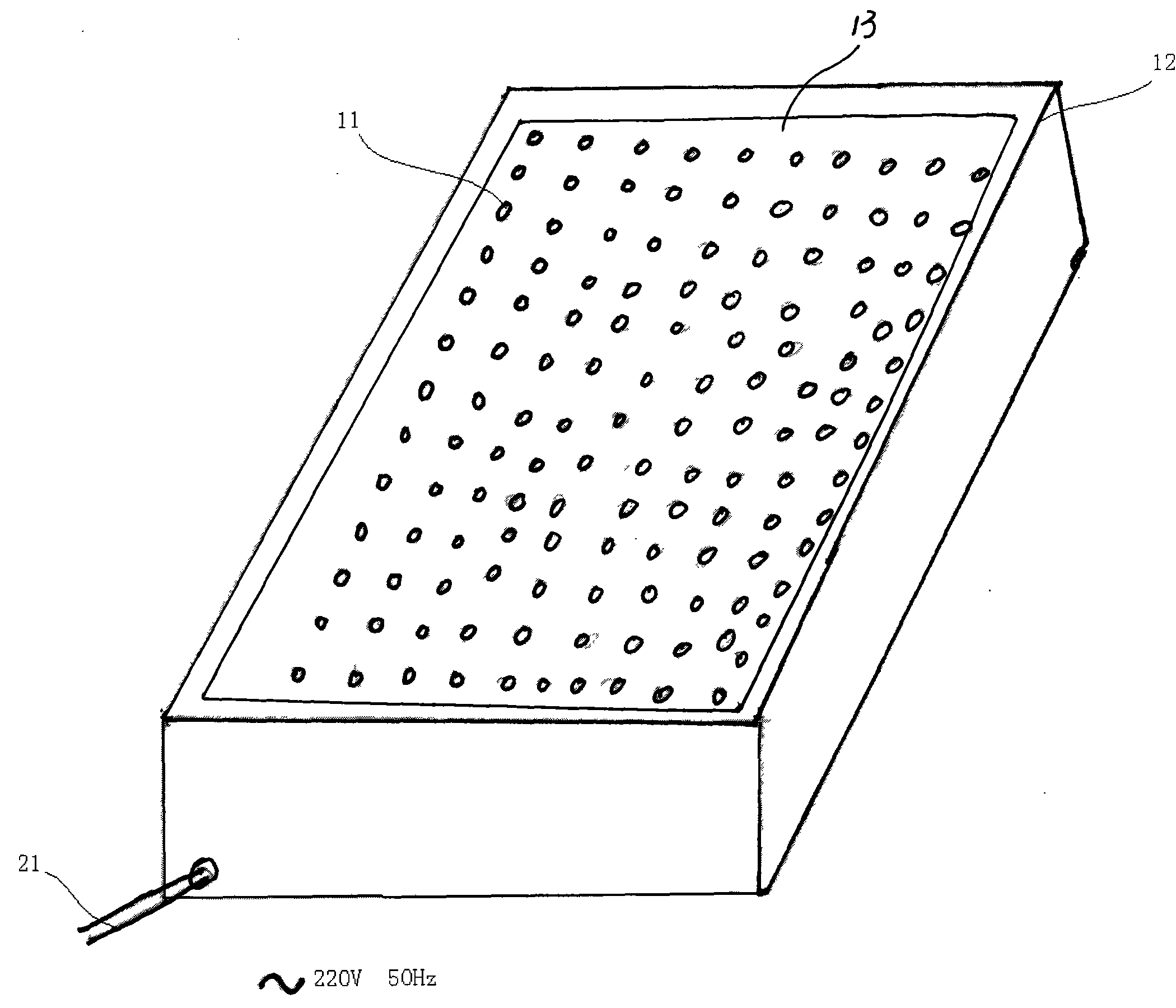

[0021] Such as figure 1 , figure 2 As shown, a LED lighting device is designed and assembled, including a DC constant voltage power supply fixed in a frame 12, a circuit board 13 for inserting a plurality of LEDs 11, and a heat sink. The DC constant voltage power supply is electrically connected to the The LED provides power, wherein: the DC constant voltage power supply can be a common switching power supply provided on the market at present, and the following conditions can be met: the provided voltage is 250 volts, and the provided current is 0.44-1.1 ampere. The connection method of the LEDs 11 inserted on the circuit board is as follows: the first number of LEDs connected in series form an LED light group, and then the second number of the LED light groups are connected in parallel to form a complete LED light module circuit, wherein the first number A quantity should meet t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com