Device and method for processing high-salinity degradation-resistant waste water

A refractory, high-salt technology, used in water/sewage treatment, anaerobic digestion treatment, chemical instruments and methods, etc., can solve problems such as changing sludge sedimentation and effluent SS, affecting biochemical effects, and deteriorating effluent quality. , to achieve the effect of strong adaptability, increasing sludge concentration and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

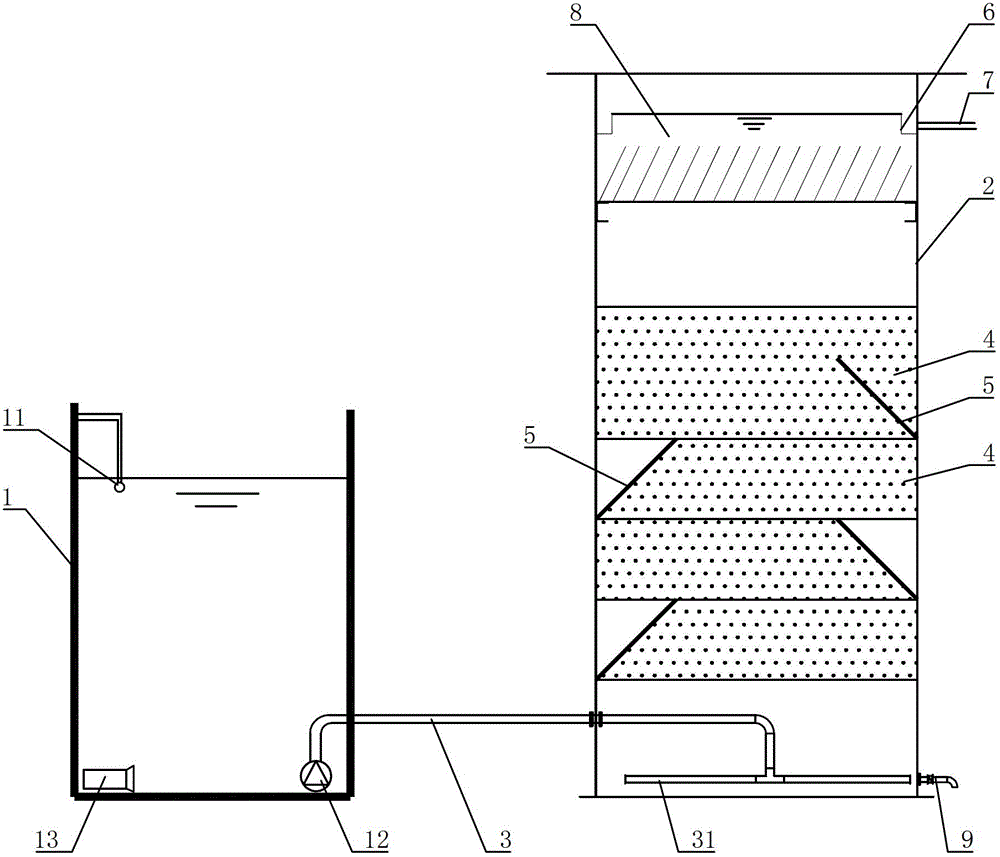

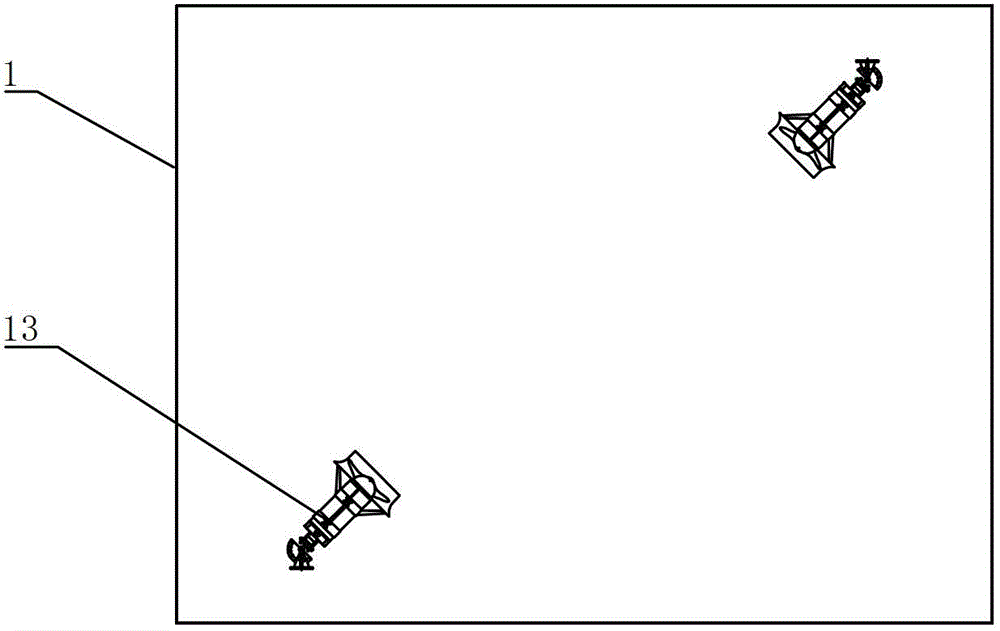

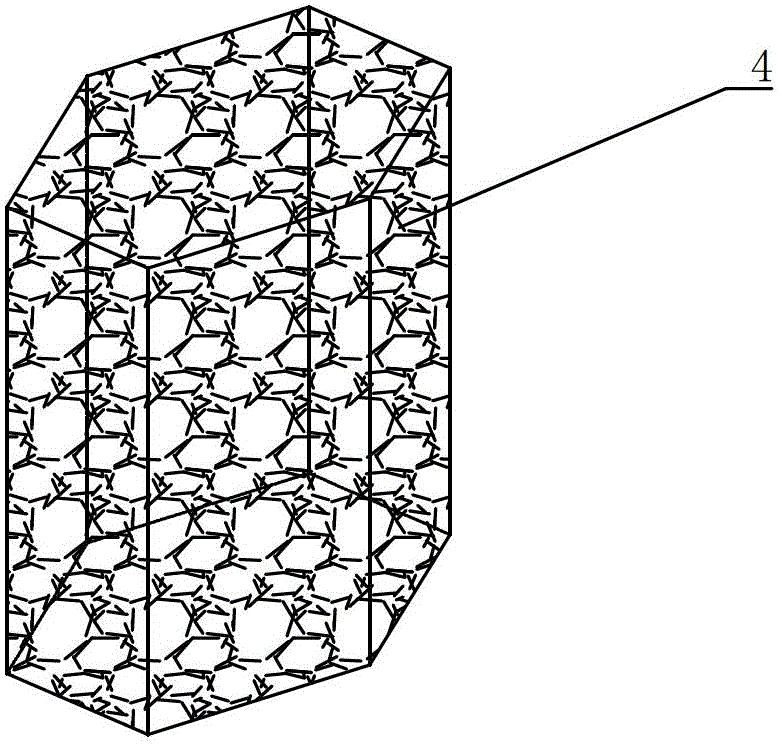

[0031] like figure 1 As shown, a device for treating high-salinity refractory wastewater includes a salinity homogeneous tank 1 and an anaerobic device 2 fed by the salinity homogeneous tank 1, and the anaerobic device 2 includes an influent at the bottom zone, the reaction zone in the middle and the water outlet zone on the top, the water inlet zone is provided with a water inlet main pipe 3 connected with the salinity homogeneous tank 1, and the reaction zone is provided with a plurality of suspended packing layers 4 from bottom to top, each suspended packing 4 A section of baffle plate 5 is correspondingly provided, and halophilic microbial communities are attached to the suspended packing layer 4. The outlet area is provided with an outlet weir 6, an outlet pipe 7 connected to the outlet weir 6, and a three-phase separator 8.

[0032] Each section of baffles 5 is tilted upwards and staggered to be positioned on the inner wall of anaerobic device 2, forming an angle of 45 d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com