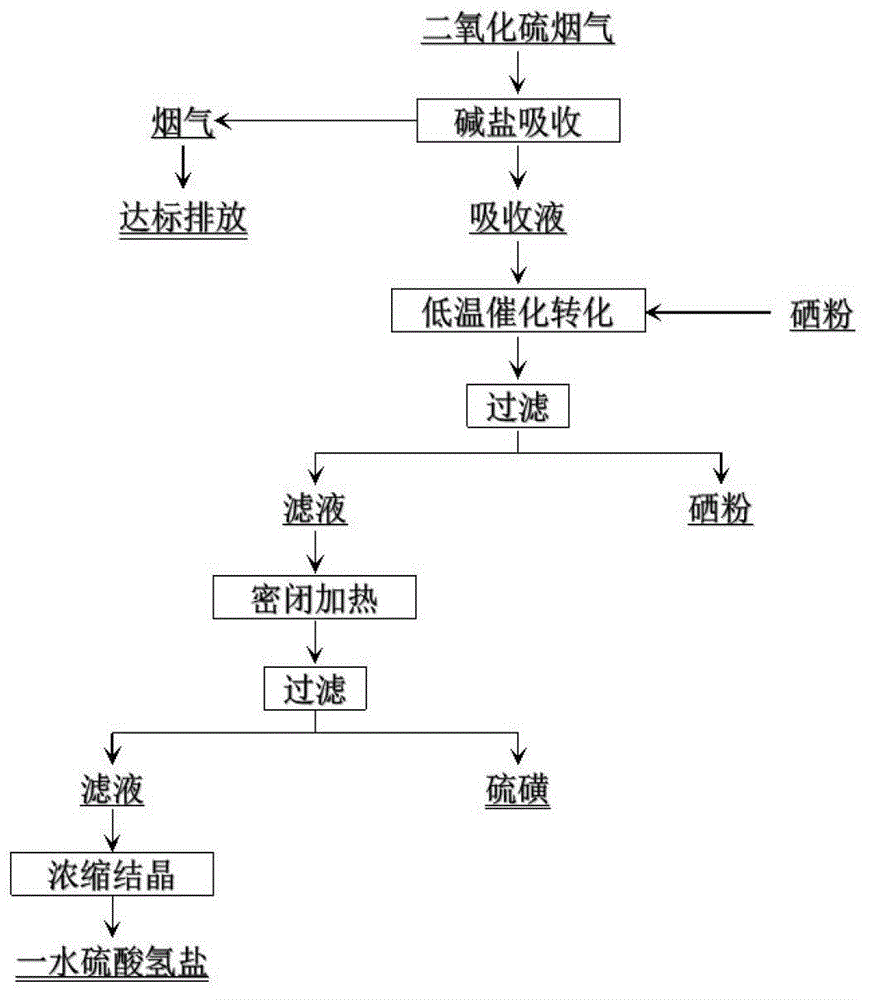

Method of sulfur recovery through sulfur dioxide flue gas cleaning and catalyzing and application of catalyst

A sulfur dioxide and catalyst technology, applied in the direction of sulfate preparation, sulfur preparation/purification, etc., can solve the problems of large consumption of NaOH, low overall economic benefits, long process flow, etc., and achieve wide concentration range, convenient transportation, and economic value high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Chemically pure sodium hydroxide, its main components are: NaOH>99.0%. Water is first-grade deionized water; simulated flue gas is SO 2 Fully mixed gas with air, the volume ratio is 3%, 97% in turn; chemically pure sulfuric acid, its main component is: sulfuric acid (H 2 SO 4 ) mass fraction ≥ 98%.

[0046]The sodium hydroxide of above-mentioned composition, is mixed with 200ml solution, and sodium hydroxide concentration is 3.0mol / L. Add the prepared sodium hydroxide solution to two bubbling absorption devices respectively, each level of solution is 100ml. Connect the two-stage absorption system. The above-mentioned sulfur dioxide-containing flue gas passes through two bubbling absorption devices at a flow rate of 0.4L / min at 25°C. A pH meter is installed on the first-stage bubbling absorption tower to measure the absorption liquid online. The pH value of the tail gas is used to analyze SO by flue gas analyzer 2 concentration. The above-mentioned flue gas is abso...

Embodiment 2

[0049] Chemically pure sodium carbonate, its main components are: Na 2 CO 3 >99.0%. Water is first-grade deionized water; simulated flue gas is SO 2 Fully mixed gas with air, the volume ratio is 3%, 97% in turn; chemically pure sulfuric acid, its main component is: sulfuric acid (H 2 SO 4 ) mass fraction ≥ 98%.

[0050] The sodium carbonate of above-mentioned composition, is mixed with 200ml solution, and sodium carbonate concentration is 0.1mol / L. Add the prepared sodium hydroxide solution to two bubbling absorption devices respectively, each level of solution is 100ml. Connect the two-stage absorption system. The above-mentioned sulfur dioxide-containing flue gas passes through two bubbling absorption devices at a flow rate of 0.4L / min at 25°C. A pH meter is installed on the first-stage bubbling absorption tower to measure the absorption liquid online. The pH value of the tail gas is used to analyze SO by flue gas analyzer 2 concentration. The above flue gas is absor...

Embodiment 3

[0053] Industrial caustic soda Class I superior product (GB209-2006), its main component is: NaOH>99.0%. Water is industrial water; contains SO 2 The flue gas is the smelting flue gas of the rotary kiln with zinc leaching slag, and its main component is SO 2 2980mg / m 3 , CO 17%, CO 2 30%, N 2 53%; first-class product of industrial sulfuric acid (GB 534-2002), its main component is: sulfuric acid (H 2 SO 4 ) mass fraction ≥ 92.5% or 98%.

[0054] The industrial caustic soda of above-mentioned composition, is mixed with 300.0L solution, filters out insoluble matter, and sodium hydroxide concentration is 1.0mol / L. Add the prepared sodium hydroxide solution to the two-stage bubbling absorption tower through the lye supply system, the first-stage absorption bubbling tower is 200L, and the second-stage absorption bubbling tower is 100L. After the above-mentioned flue gas is cooled to 30°C and the heavy metal dust is removed, the gas is evenly distributed through the gas dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com