Zipper tooth oxidation line with shafts and bearing seats having longer service lives

A bearing seat and oxidation line technology, applied in the field of zipper sprocket oxidation line, can solve the problems that affect the stable production of oxidation equipment, the tension of the cloth belt, the lower shaft and the bearing seat are easily corroded, and difficult to replace, so as to ensure stable operation performance, easy maintenance, and reduced maintenance times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

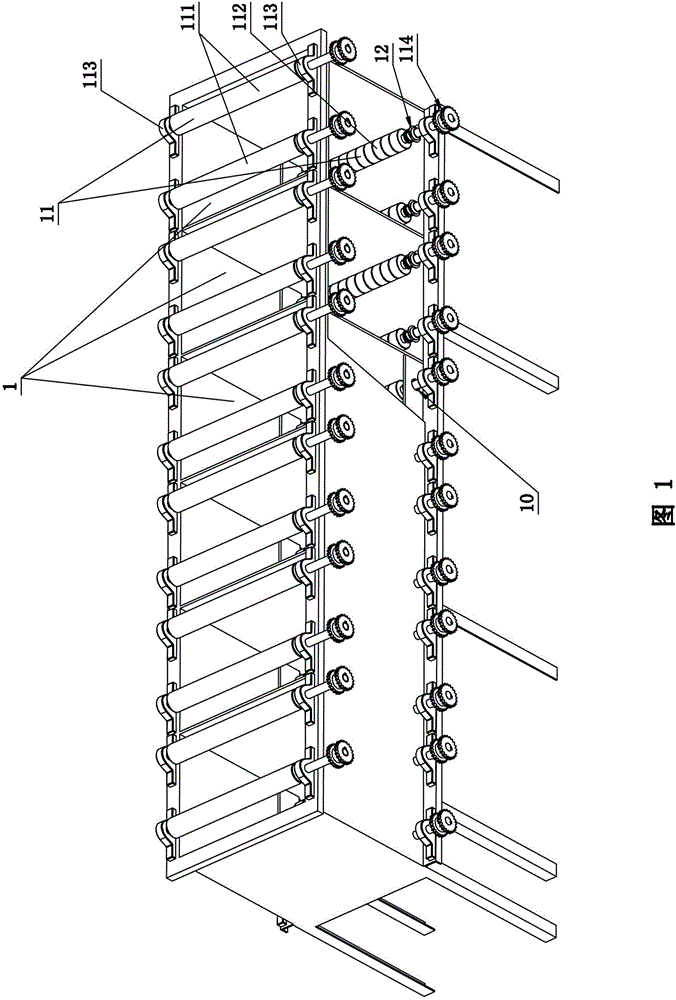

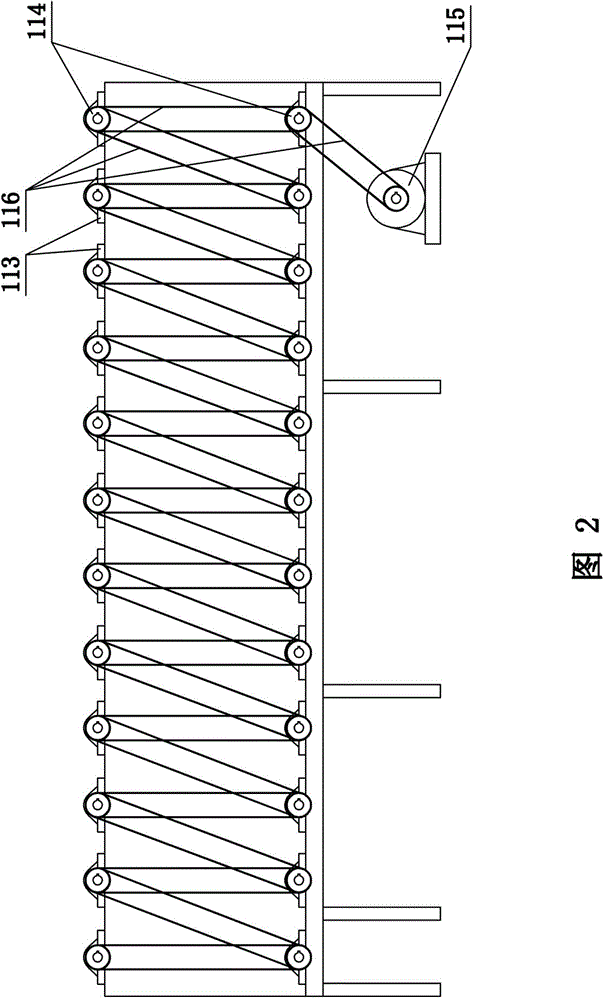

[0015] refer to figure 1 , figure 2 , a zipper element oxidation line with longer service life for shafts and bearing housings, comprising at least one oxidation tank 1 equipped with at least one set of rotating shaft groups 11 including upper shafts arranged in parallel 111 and the lower shaft 112, the upper shaft 111 adopts the upper shaft 111 with 45# hard chrome plating on the outer surface, and the upper shaft 111 covered with PA1010 after heat treatment, and the lower shaft 112 adopts the lower shaft 112 with 40Cr surface hard chrome plating and heat treatment; the upper shaft 111 and the lower shaft The two ends of 112 are respectively equipped with bearing housings 113, the bearing housings 113 are assembled on the oxidation tank 1, the lower shaft 112 is assembled in the oxidation tank 1 groove, and the bearing housings 113 at both ends of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com