Dust collecting device

A dust-collecting device and dust-collecting technology, applied in the directions of portable impact tools, maintenance and safety accessories, manufacturing tools, etc., to achieve the effect of reasonable dust collection, reasonable collection, and prevention of carrying static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

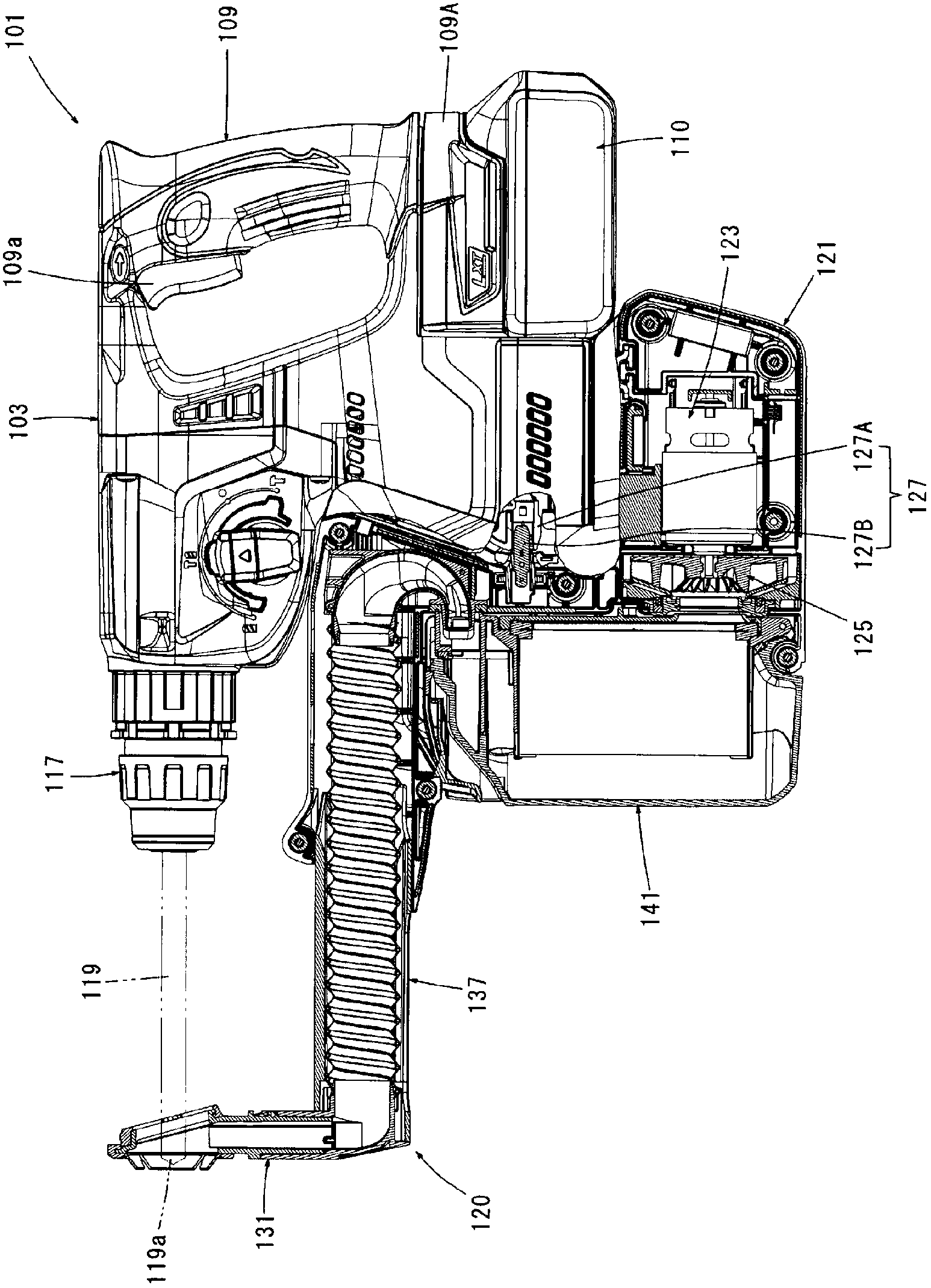

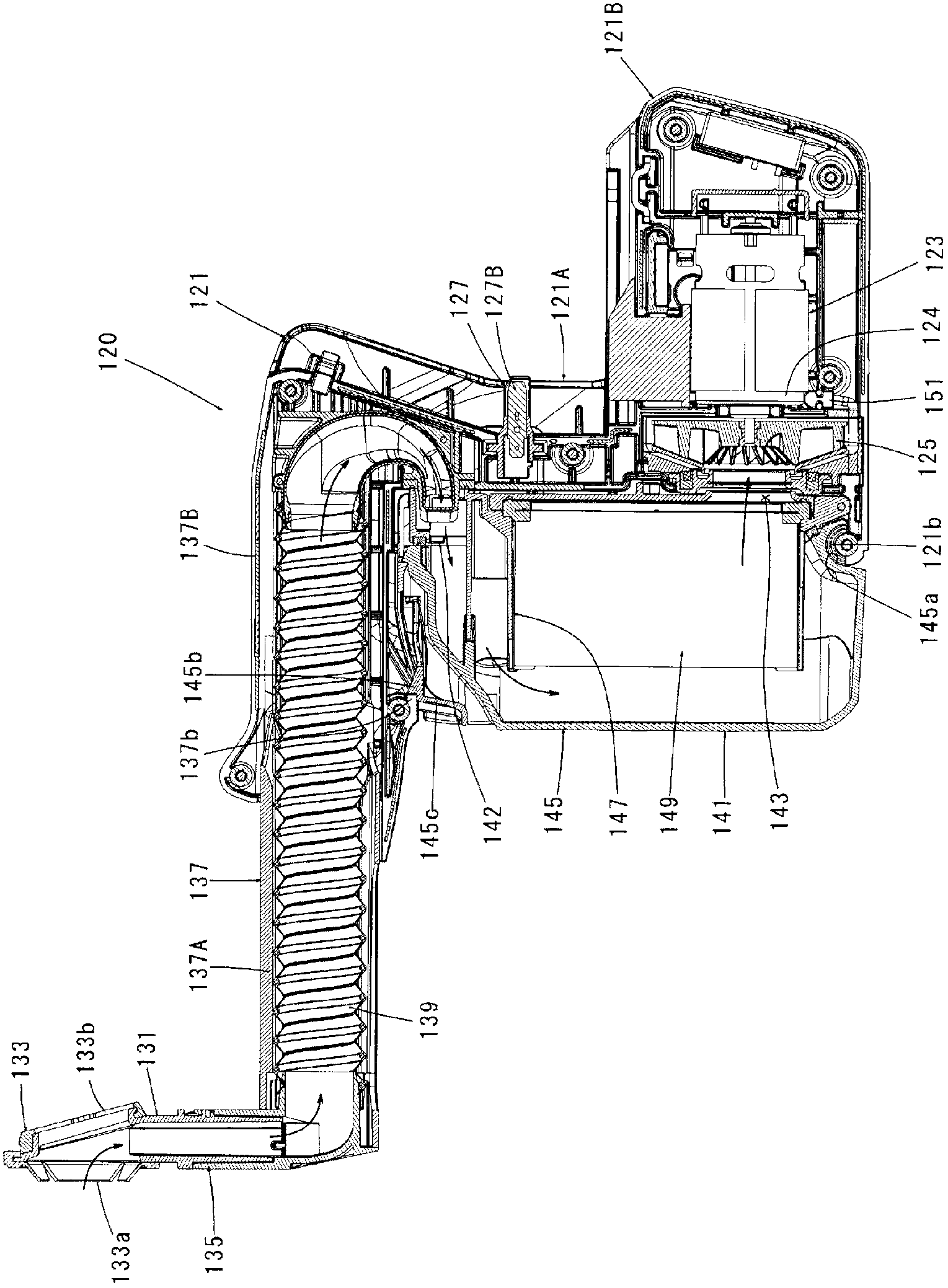

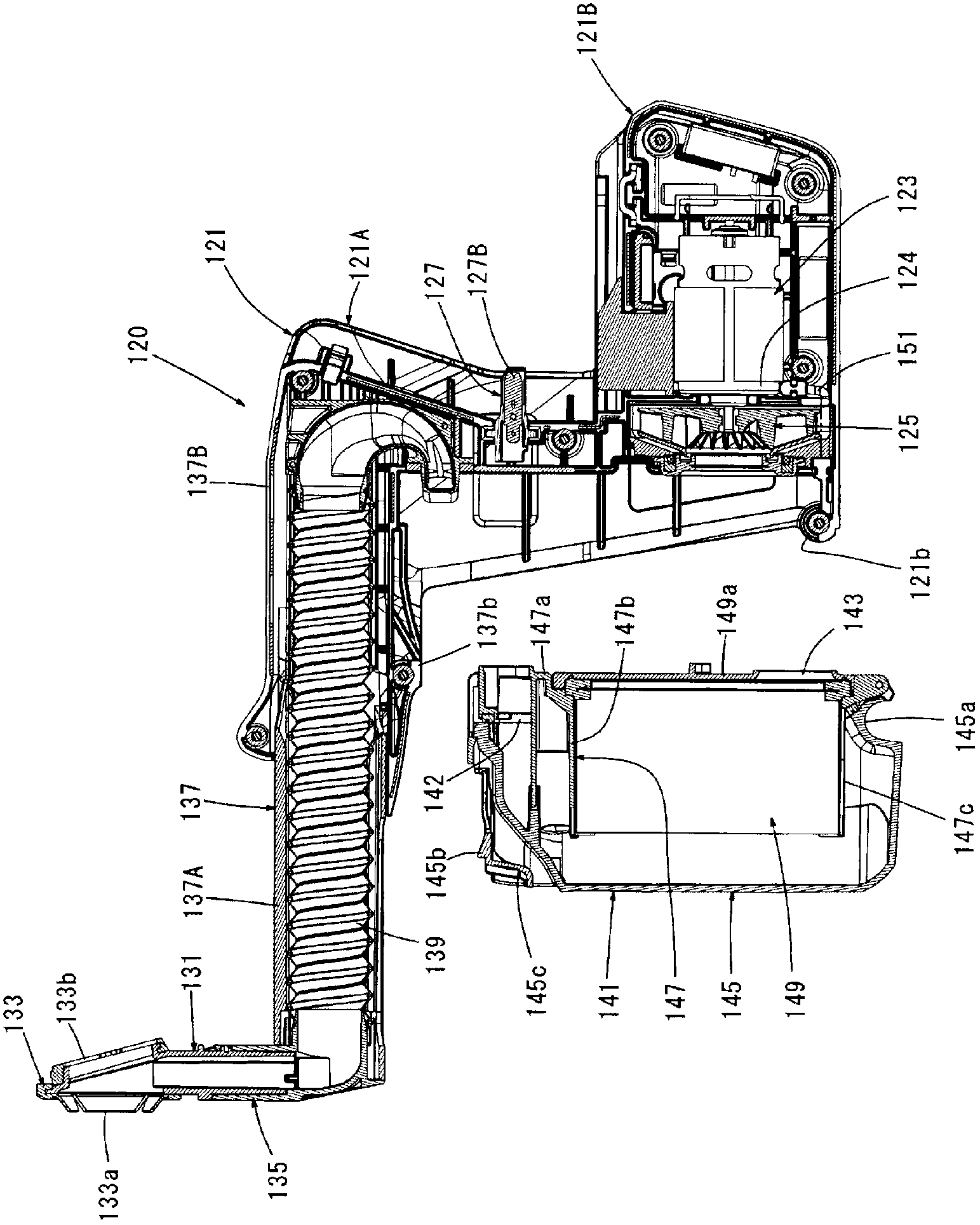

[0029] Below, refer to Figure 1~Figure 5 Embodiments of the present invention will be described in detail. This embodiment will be described using a cordless hammer drill as an example of a power tool. Such as figure 1 As shown, viewed generally, the main body of the electric hammer drill 101 of this embodiment is constituted by: the main body 103 as the main body of the working tool forming the outer contour of the electric hammer drill 101 ; An electric hammer drill 119 at the front end region (left side in the drawing) of the main body 103 ; and a handle 109 connected to the opposite side of the main body 103 to the electric hammer drill 119 . The hammer drill 119 is held by the tool holder 117 in a state where relative reciprocation is possible in the longitudinal direction of the hammer drill 119 and relative rotation in the circumferential direction of the hammer drill 119 is restricted. The electric hammer drill 119 corresponds to the "tip tool" in the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com