Vibrating screen

A technology of vibrating screen and screen box, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of production trouble, high cost, screen paste, etc., and achieve good screening effect, large processing capacity and strong practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

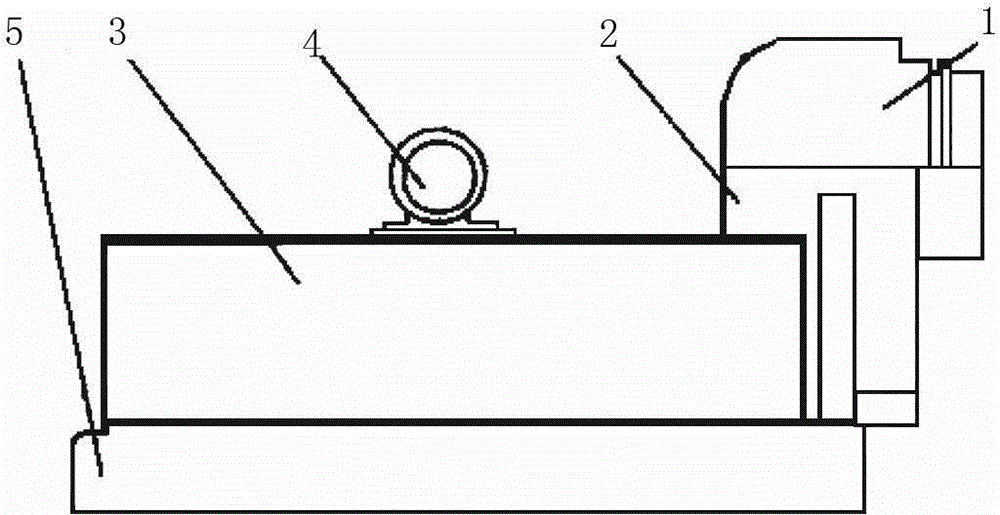

[0014] A vibrating screen according to the present invention, the pipe interface 1, the buffer box 2, and the screen box 3 are connected in sequence, the ellipse exciter 4 is arranged on the upper part of the screen box 3, the bottom of the screen box 3 is provided with a base 5, and the screen box 3 and the vibrating screen Elastic material is arranged between, the present invention sets the rotating speed of ellipse actuator 4 to be 1450N / R per minute, and the vibration direction angle is 50°. The inside of the screen box 3 is provided with two layers of screens, the screens on the top and bottom of the screen box 3 are respectively 30 mesh, and the bottom screen is 170 mesh. The vibrating screen also includes a motor, The motor is connected with the elliptical actuator 4 .

[0015] Start the motor when in use, and the material enters from the pipe interface 1 and then enters the screen box 3 after being buffered by the buffer box 2. The elliptical actuator 4 drives the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com