Ore dressing method of spodumene quarry

A beneficiation method and technology of spodumene ore, applied in flotation, solid separation, etc., can solve problems such as low recovery rate, poor concentrate quality, and difficult separation of spodumene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

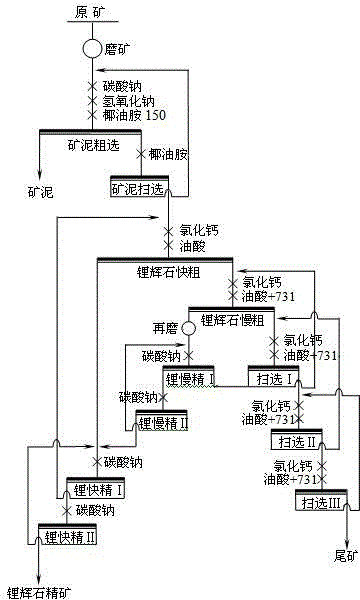

Image

Examples

Embodiment 1

[0032] Selected raw ore containing Li 2 O0.73%, the main minerals are spodumene, spodumene, beryl, muscovite, sericite, quartz, feldspar, fluorite, tourmaline, kaolinite, calcite, etc., lithium minerals embedded in the ore The characteristics are complex, the embedded particle size is uneven, and mainly fine particles, and the monomer dissociation is poor. Spodumene concentrate obtained by traditional spodumene flotation process contains Li 2 O4.53%, recovery rate 62.37%.

[0033] The complex and refractory low-grade spodumene ore is sorted by adopting the new spodumene flotation process of the present invention, and the sorting steps are:

[0034] (1) Grinding the raw ore, the grinding fineness -0.074mm content is 78%;

[0035] (2) The finely ground pulp is subjected to rough separation of slime to obtain slime products and tailings I. The process conditions of the flotation process are: adding 800g / t of sodium carbonate and 600g / t of sodium hydroxide, and the action time ...

Embodiment 2

[0044] Selected raw ore containing Li 2 O1.12%, the main minerals are spodumene, quartz, feldspar, beryl, sericite, fluorite, muscovite, kaolinite, topaz, tourmaline, calcite, etc. The characteristics of lithium mineral intercalation in the ore are complex, The intercalation particle size is extremely dispersed, and mainly fine particles, and the dissociation of monomers is poor. Spodumene concentrate obtained by traditional spodumene flotation process contains Li 2 O5.11%, recovery rate 66.12%.

[0045] The complex and refractory low-grade spodumene ore is sorted by adopting the new spodumene flotation process of the present invention, and the sorting steps are:

[0046] (1) Grinding the raw ore, the grinding fineness -0.074mm content is 76%;

[0047] (2) The finely ground pulp is subjected to rough separation of slime to obtain slime products and tailings I. The process conditions of the flotation process are: add 750g / t of sodium carbonate and 610g / t of sodium hydroxide,...

Embodiment 3

[0056] Selected raw ore containing Li 2 O0.86%, the main minerals are spodumene, saspodumene, muscovite, beryl, sericite, quartz, calcite, feldspar, fluorite, tourmaline, kaolinite, etc. Lithium minerals are embedded in the ore The characteristics are complex, the embedded particle size is scattered and uneven, mainly fine particles, and the monomer dissociation is poor. Spodumene concentrate obtained by traditional spodumene flotation process contains Li 2 O4.88%, recovery rate 63.37%.

[0057] The complex and refractory low-grade spodumene ore is sorted by adopting the new spodumene flotation process of the present invention, and the sorting steps are:

[0058] (1) Grinding the raw ore, the grinding fineness -0.074mm content is 78%;

[0059] (2) The finely ground pulp is subjected to rough separation of slime to obtain slime products and tailings I. The process conditions of the flotation process are: adding 800g / t of sodium carbonate and 600g / t of sodium hydroxide, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com