Damper

A damper and damping component technology, applied in shock absorbers, shock absorbers, liquid shock absorbers, etc., can solve problems such as high cost and manual execution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

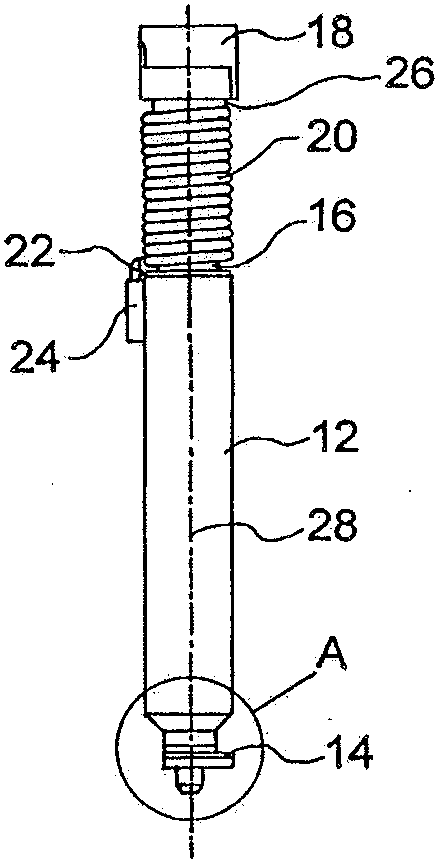

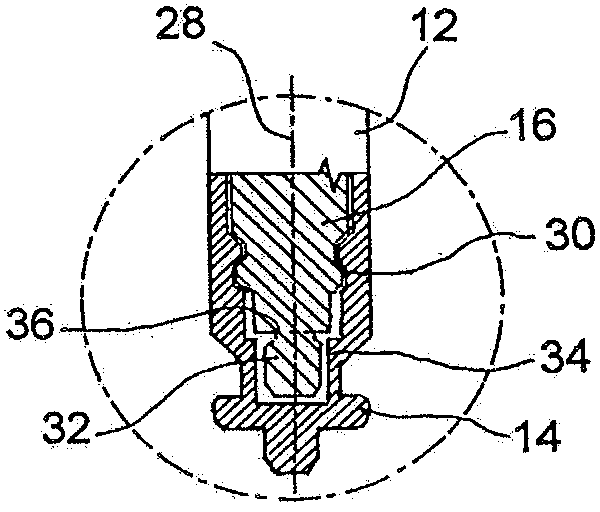

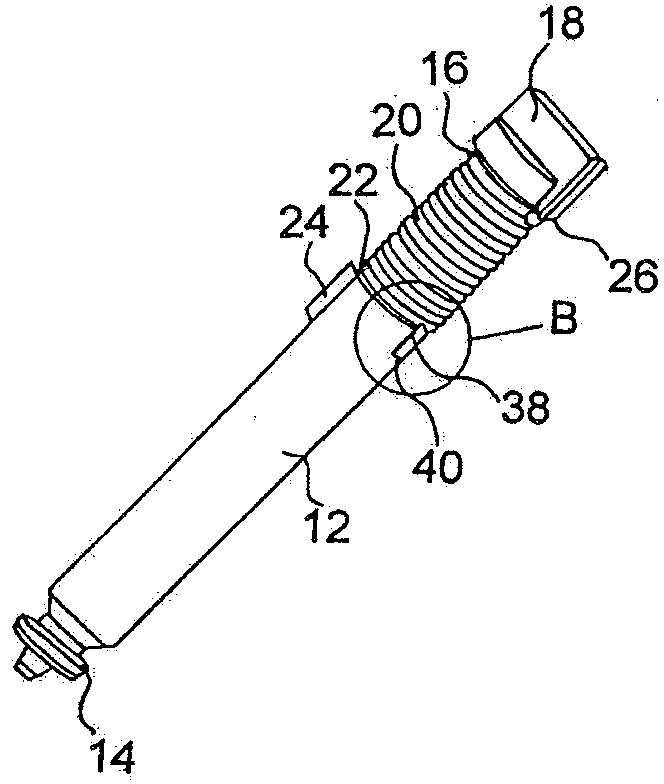

[0027] Unless otherwise indicated, the same reference numerals in each figure indicate the same objects. figure 1 with 2 The damper according to the present invention is shown for damping the movement of a component, such as a cover provided inside an automobile. The damper has a damper housing 12, which is substantially cylindrical in this example. The damper housing 12 defines a cavity that is also substantially cylindrical in which the damper fluid (such as silicone fluid) is located. The damper housing 12 has a protrusion 14 at its front end, thereby enabling the damper to be installed in a component in a reliable anti-rotation manner. The damper also has a damper element 16, which in this case is a substantially cylindrical rotating piston 16 partially located in the damper housing 12. The rotating piston 16 has a matching head 18 at its end remote from the damper housing 12, and the head 18 is also used for mounting on the component. The rotary piston 16 is rotatably in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com