Quantum dot electroluminescent device and preparation method thereof

An electroluminescent device, quantum dot light emitting technology, applied in the direction of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as difficult to achieve HOMO energy level matching, achieve high-efficiency injection and transmission, good color purity , good thermal stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

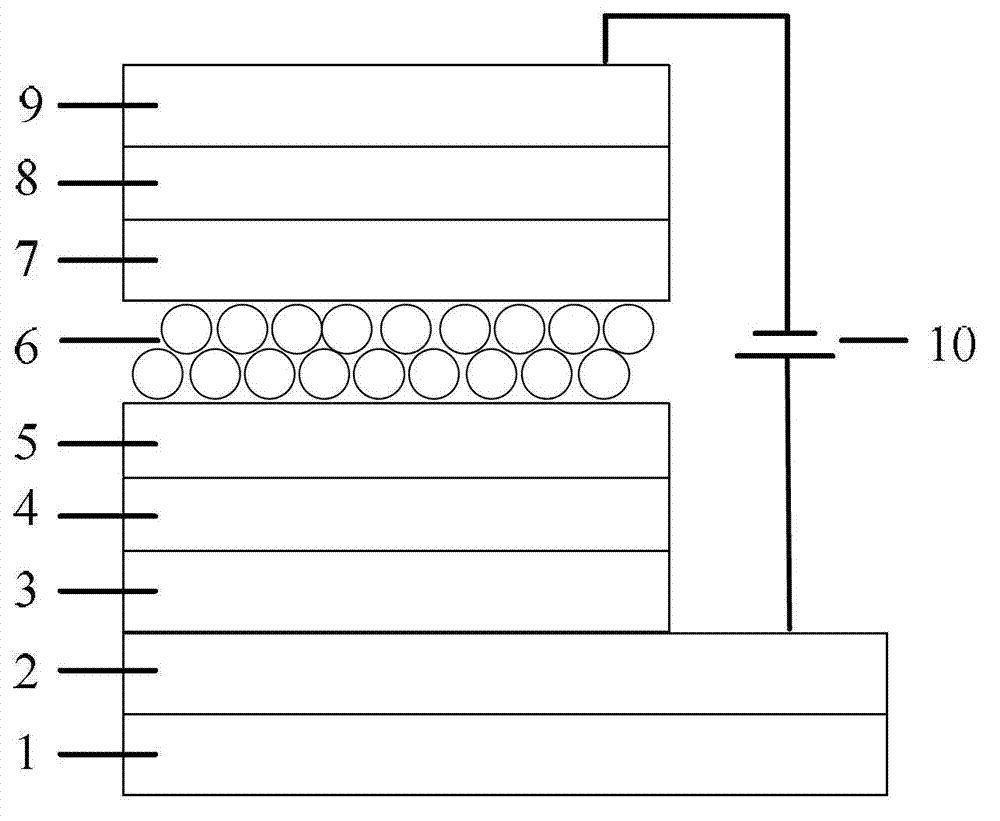

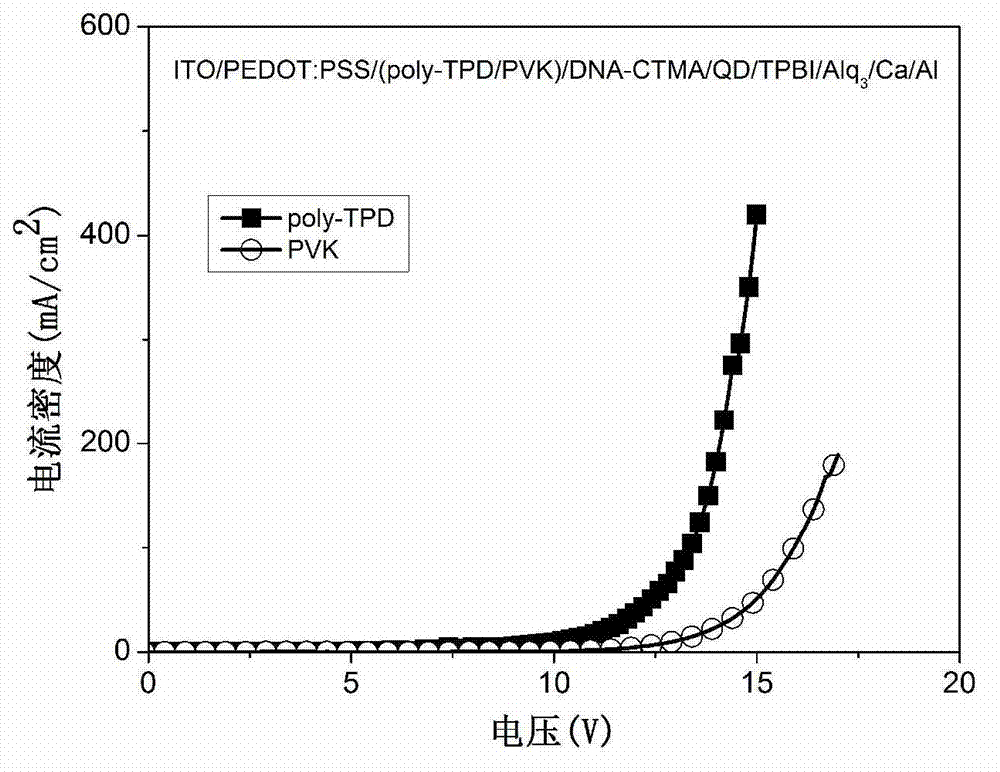

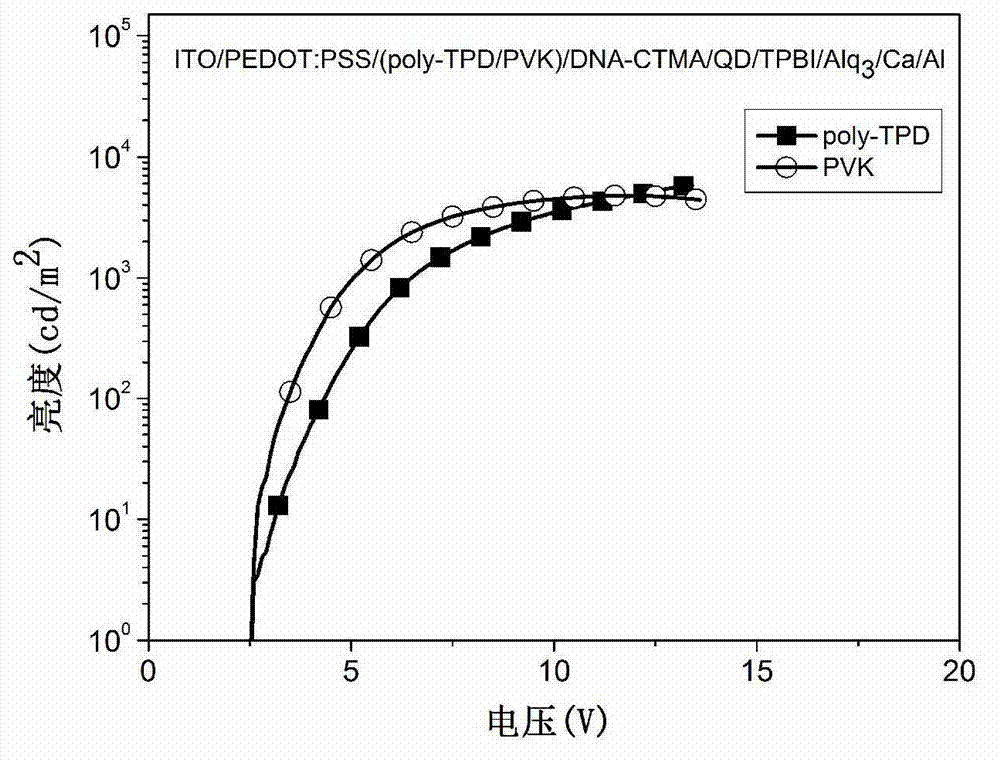

Embodiment 1

[0034] The ITO glass is cleaned and dried by boiling with various solvents and deionized water ultrasonically. Then, the PEDOT:PSS film was covered on the ITO by the method of spin coating, the film thickness was 25nm, and the spin coating rate was 2000rpm. On the PEDOT:PSS film, continue to spin-coat a layer of 25nm thick poly-TPD film at a spin-coating rate of 3000rpm, then spin-coat a layer of 20nm-thick DNA-CTMA film on it at a spin-coating rate of 4000rpm, and then CdSe / CdS / ZnS (core / shell / shell) quantum dots were spin-coated on the DNA-CTMA film at a spin-coating rate of 1500rpm. In a high vacuum environment, TPBI, Alq 3 successively deposited on the QD layer, TPBI film thickness 15nm, Alq 3 The film thickness is 20nm, and the deposition rate is 0.1-0.4nm / s. in Alq 3 Continue thermally depositing a metal layer on top, the metal layer is composed of Ca / Al, and the deposition rate is 0.4-1.0nm / s. The turn-on voltage of the device is 3.2V, and the maximum brightness i...

Embodiment 2

[0036]The ITO glass is cleaned and dried by boiling with various solvents and deionized water ultrasonically. Then, the PEDOT:PSS thin film was covered on the ITO by the method of spin coating, the thickness of the film was 25nm, and the spin coating speed was 2000rpm. On the PEDOT:PSS film, continue to spin-coat a layer of 25nm thick PVK film at a spin-coating rate of 3000rpm, then spin-coat a layer of 20nm-thick DNA-CTMA film at a spin-coating rate of 4000rpm, and then CdSe / CdS / ZnS The (core / shell / shell) quantum dots were spin-coated on the DNA-CTMA film at a spin-coating rate of 1500 rpm. In a high vacuum environment, TPBI, Alq 3 successively deposited on the QD layer, TPBI film thickness 15nm, Alq 3 The film thickness is 20nm, and the deposition rate is 0.1-0.4nm / s. in Alq 3 Continue thermally depositing a metal layer on top, the metal layer is composed of Ca / Al, and the deposition rate is 0.4-1.0nm / s. The turn-on voltage of the device is 4.2V, and the maximum brightn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com