Method for preparing graphene-based electrode material for super-capacitor

A graphene-based and electrode material technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve problems such as easy pulverization, poor conductivity, and weak combination of composite materials and substrates, so as to prevent agglomeration, Improved contact and low-cost reaction raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

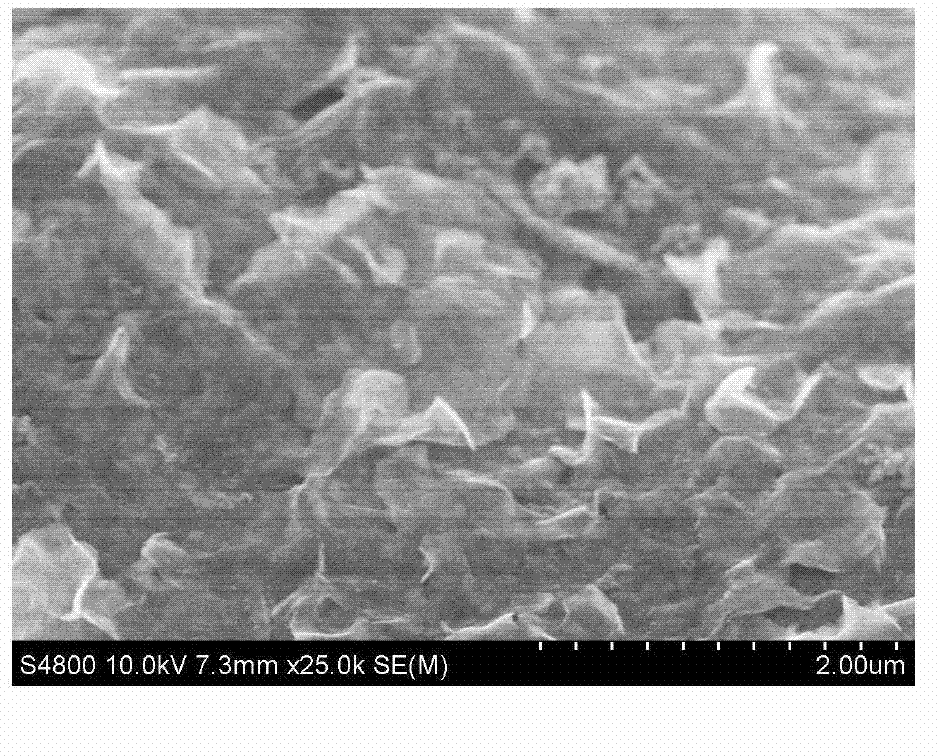

[0017] Cut the foamed nickel into a uniform area (4cm x 4cm), and clean it ultrasonically in acetone, ethanol, and water. Take a piece of foamed nickel and place it on the heating plate. Disperse 20 mg of graphene oxide and 240 mg of nickel acetate in a mixed solution of 5 ml of water, 20 ml of ethanol and 20 ml of ethylene glycol, stir well and transfer to a syringe. A high-voltage electrostatic field of 20kV is added between the syringe and the heating plate, and the liquid is fed at a speed of 3ml / h. The heating temperature of the heating plate is 250°C. After 2h of deposition, graphene-nickel oxide / foamed nickel composite material was obtained. figure 1 It is a scanning electron microscope picture of graphene / nickel oxide magnified 25,000 times. It can be seen that the graphene exhibits gauze-like folds and does not aggregate into large lumps.

Embodiment 2

[0019] Cut the foamed nickel into a uniform area (4cm x 4cm), and clean it ultrasonically in acetone, ethanol, and water. Take a piece of foamed nickel and place it on the heating plate. Disperse 20 mg of graphene oxide in a mixed solution of 5 ml of water, 20 ml of ethanol and 20 ml of ethylene glycol, stir well and transfer to a syringe. A high-voltage electrostatic field of 20kV is added between the syringe and the heating plate, and the liquid is fed at a speed of 3ml / h. The heating temperature of the heating plate is 250°C. After 2 hours of deposition, a graphene / nickel foam composite was obtained. In this scheme, only graphite oxide is used and no other active materials are added. The resulting film was like the gauze in Example 1.

Embodiment 3

[0021] The stainless steel sheet was cleaned ultrasonically in acetone, ethanol, and water in sequence. Take a piece of stainless steel and place it on the heating plate. Disperse 20 mg of graphene oxide and 240 mg of nickel acetate in a mixed solution of 5 ml of water, 20 ml of ethanol and 200 ml of ethylene glycol, stir well and transfer to a syringe. A high-voltage electrostatic field of 20kV is added between the syringe and the heating plate, and the liquid is fed at a speed of 3ml / h. The heating temperature of the heating plate is 250°C. After 2 hours of deposition, the graphene-active material / current collector composite material was obtained. In this scheme, stainless steel sheet is used as the current collector, and the others are unchanged. The graphene / nickel oxide composite material in the form of a gauze as in Example 1 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com