Modeling method for optical proximity correction process model

A technology of optical proximity effect and process model, which is applied in the field of modeling of optical proximity effect correction process model, can solve the problems of exposure capability gap, unscientific, different observers, etc., to ensure accuracy, reliability and stability, speed up fitting and Convergence time and effect of reducing the amount of measurement data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

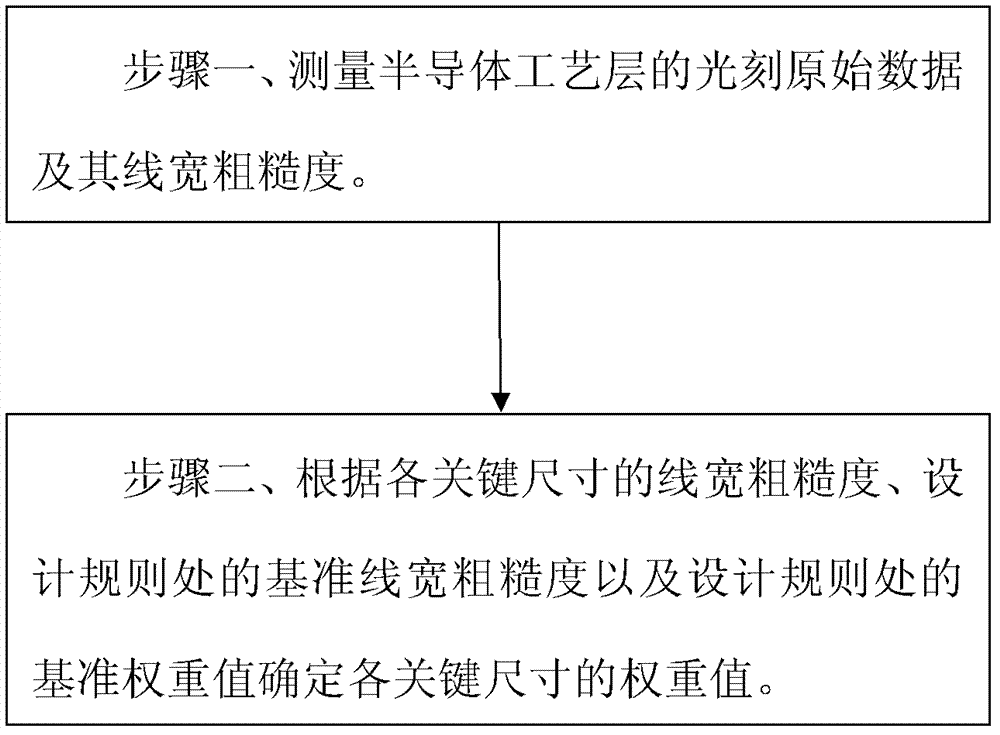

[0023] Such as figure 1 Shown is the flowchart of the method of the embodiment of the present invention. The modeling method of the optical proximity effect correction process model in the embodiment of the present invention includes steps:

[0024] Step 1. Using a scanning electron microscope to measure the lithography raw data of the semiconductor process layer and the line width roughness of the lithography raw data; the lithography raw data includes the measured values of multiple key dimensions; the lithography raw data The line width roughness includes the line width roughness for each of the critical dimension measurements.

[0025] Step 2. Determine each key dimension according to the line width roughness of the measured value of each critical dimension, the reference line width roughness at the design rule of the semiconductor process layer, and the reference weight value at the design rule of the semiconductor process layer. The weight value of the key dimension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com