Insulation sealing plug

An insulating sealing and plugging technology, which is applied in the direction of insulators, pipes/pipe joints/fittings, flange connections, etc., can solve the problems of difficult installation of sealing plugs, threats to personal safety of equipment, threats to equipment operation safety, etc., to achieve convenience The effect of installation and maintenance, reliable mechanical structure strength and stable air pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

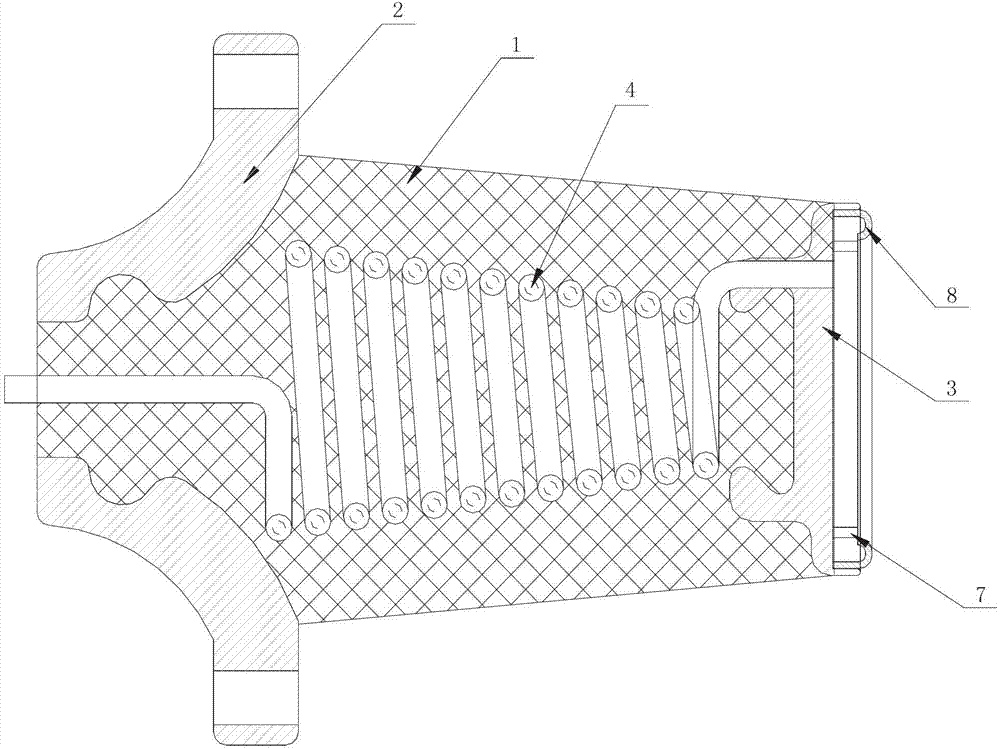

[0014] The present invention includes a main insulator 1 and a top sealing flange 2 formed on one end of the main insulator 1, the other end of the main insulator 1 is provided with a bottom sealing flange 3; the main insulator 1 is provided with an exhaust device; the The exhaust is embedded within the main insulator 1 . The main insulator 1 is made of solid insulating material, electrodes for reducing electric field stress are installed on the top sealing flange 2 and the bottom sealing flange 3, and the main insulator is integrally formed with the sealing flange seat. Its mechanical structure has reliable strength and uniform electric field strength, and it can be equipped with external plug-in electrical equipment, which is convenient for installation and maintenance.

[0015] The exhaust device includes an exhaust pipe 4 wound in the main insulator 1 in a spiral shape, and one end of the exhaust pipe 4 is wound to the top of the main insulator 1 and then passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com