Electromagnetic reversing valve

An electromagnetic reversing valve and electromagnet technology, applied in the field of hydraulic machinery, can solve problems such as unreliable action, low reversing frequency, inconvenient installation, etc., and achieve the effect of filling the domestic gap, high reversing frequency, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

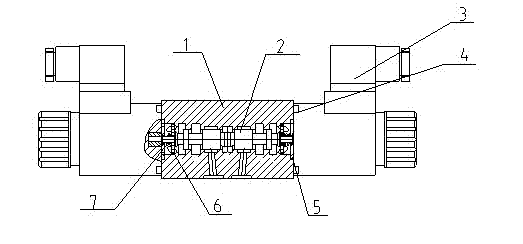

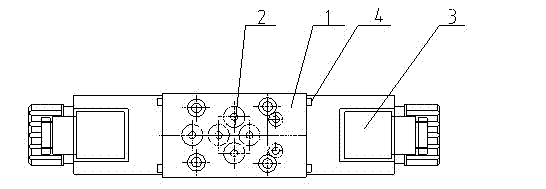

[0014] like figure 1 and 2 As shown, the electromagnetic reversing valve of the present invention includes a valve body 1, a valve core 2 and an electromagnet 3, and the valve body 1, the valve core 2 and the electromagnet 3 are connected by screws 4, and the valve core 2 and the valve body 1 is provided with a spring 7, a sealing ring 5 is provided between the valve body 1 and the valve core 2, a spring pad 6 is provided between the spring 7 and the valve core 2, the structure is compact, the weight is light, and the installation is convenient. The reversing frequency is high and the action is reliable. It is used in marine control equipment, replacing imported special valves, filling the domestic gap, and having a huge impact on promoting production and expanding employment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com