Continuous construction method for concrete pile steel pipe column

A technology of concrete piles and construction methods, applied in the field of building foundation engineering, can solve the problems of unsatisfactory connection strength of concrete piles and steel pipe columns, uncontinuous construction of concrete piles and steel pipe columns, long construction period, etc., so as to shorten the construction period and reduce the Construction cost and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described with a specific embodiment below, a kind of continuous construction method of concrete pile steel tube column, comprises the following steps:

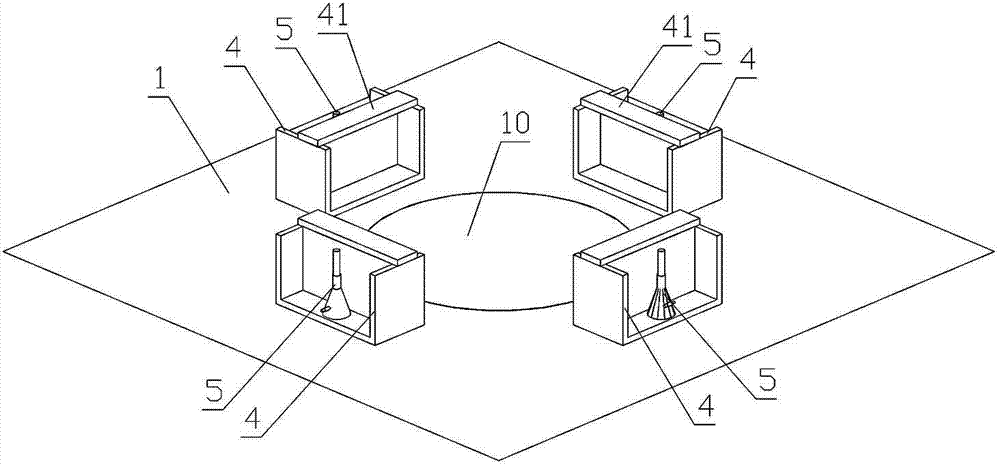

[0037] step 1. The ground is leveled and hardened to form the construction ground 1, and then the pile hole 10 is positioned at the pile position of the construction ground 1, and the diameter of the pile hole 10 is 2m (such as figure 1 shown);

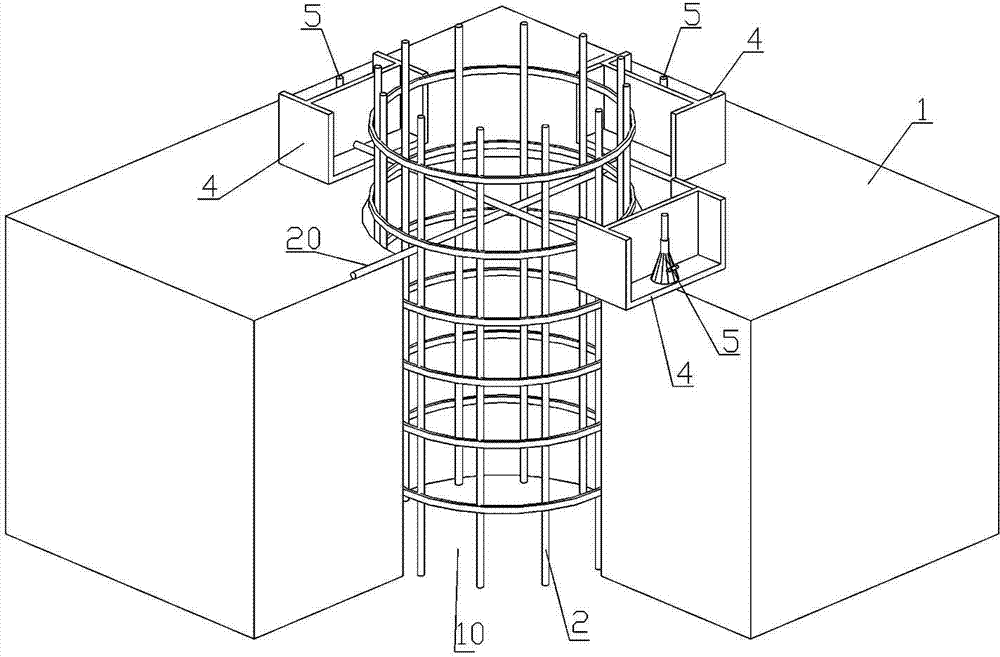

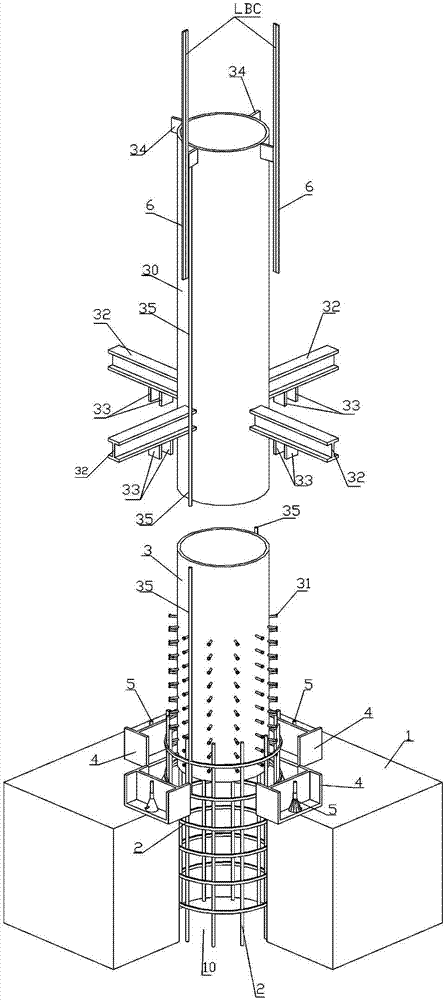

[0038] Step 2. Prefabricated reinforcement cage 2, steel pipe 3 and steel support 4, such as image 3 As shown, the outer diameter of the steel pipe 3 is 600mm, the length of the steel pipe 3 is 17m, the steel nail 31 with a length of 100mm is welded horizontally outside the 1.2m section of the lower end of the steel pipe 3, and the upper end of the steel pipe 3 is horizontally symmetrically provided with 4 The root cross-section is an I-shaped support steel bar 32, the bottom surface of the support steel bar 32 is welded with a clampin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com