Method for synthesis of tetracalcium aluminoferrite by sol-gel technology

A technology of tetracalcium ferric aluminate and gel method, applied in chemical instruments and methods, iron compounds, inorganic chemistry, etc., can solve the problems of high sintering temperature, low product purity, high energy consumption, etc., to overcome calcination high temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

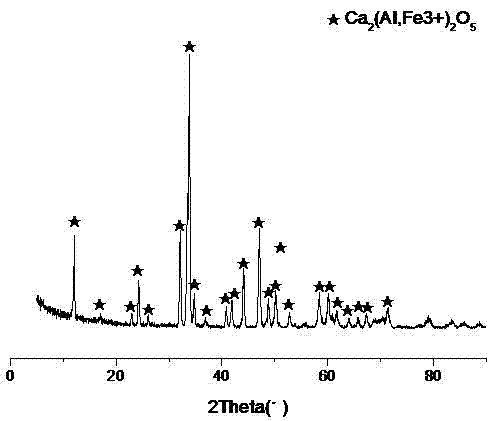

Image

Examples

Embodiment 1

[0029] Embodiment 1, a kind of method for synthesizing tetracalcium aluminoferrite by sol-gel method, the weight ratio of its raw material is: Ca(NO 3 ) 2 4H 2 O 100, Al(NO 3 ) 3 9H 2 O 79.4, Fe(NO 3 ) 3 9H 2 O 85.6, citric acid monohydrate 178.0, ethylene glycol 105.1 and water 600. The following synthesis method was adopted: on a magnetic stirrer, heated at 50°C, Ca(NO 3 ) 2 4H 2 O, Al(NO 3 ) 3 9H 2 O, Fe(NO 3 ) 3 9H 2 Add O into water respectively, heat and stir for 30 minutes until completely dissolved; add white citric acid monohydrate particles into the mixture of three nitrate solutions, heat and stir for 50 minutes to obtain a clear light yellow solution; add ethylene glycol to light yellow nitric acid In the salt-citric acid chelate solution, an esterification reaction occurs, and the reaction is carried out at a temperature of 50° C. for 40 minutes; the temperature of the magnetic stirrer is adjusted to 80° C., and aged for 6 hours to obtain a viscous...

Embodiment 2

[0030] Embodiment 2, a kind of method for synthesizing tetracalcium aluminoferrite by sol-gel method, the weight ratio of its raw material is: Ca(NO 3 ) 2 4H 2 O 100, Al(NO 3 ) 3 9H 2 O 79.4, Fe(NO 3 ) 3 9H 2 O 85.6, citric acid monohydrate 178.0, ethylene glycol 160 and water 800. The following synthesis method was adopted: on a magnetic stirrer, heated at 55°C, Ca(NO 3 ) 2 4H 2 O, Al(NO 3 )3 9H 2 O, Fe(NO 3 ) 3 9H 2 Add O into water respectively, heat and stir for 25 minutes until completely dissolved; add white citric acid monohydrate granules to the mixture of three nitrate solutions, heat and stir for 45 minutes to obtain a clear light yellow solution; add ethylene glycol to light yellow nitric acid In the salt-citric acid chelate solution, an esterification reaction occurs, and react at a temperature of 55°C for 35min; adjust the temperature of the magnetic stirrer to 83°C, and age for 5h to obtain a viscous wet gel; put the wet gel at a temperature of Dr...

Embodiment 3

[0031] Embodiment 3, a kind of method for synthesizing tetracalcium aluminoferrite by sol-gel method, the weight ratio of its raw material is: Ca(NO 3 ) 2 4H 2 O 100, Al(NO 3 ) 3 9H 2 O 79.4, Fe(NO 3 ) 3 9H 2 O 85.6, citric acid monohydrate 178.0, ethylene glycol 210.2 and water 1000. The following synthesis method was adopted: on a magnetic stirrer, heated at 60°C, Ca(NO 3 ) 2 4H 2 O, Al(NO 3 ) 3 9H 2 O, Fe(NO 3 ) 3 9H 2 Add O into water respectively, heat and stir for 20 minutes until completely dissolved; add white citric acid monohydrate particles into the mixture of three nitrate solutions, heat and stir for 40 minutes to obtain a clear light yellow solution; add ethylene glycol to light yellow nitric acid In the salt-citric acid chelate solution, an esterification reaction occurs, and react at a temperature of 60°C for 30min; adjust the temperature of the magnetic stirrer to 85°C, and age for 4h to obtain a viscous wet gel; put the wet gel at a temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com