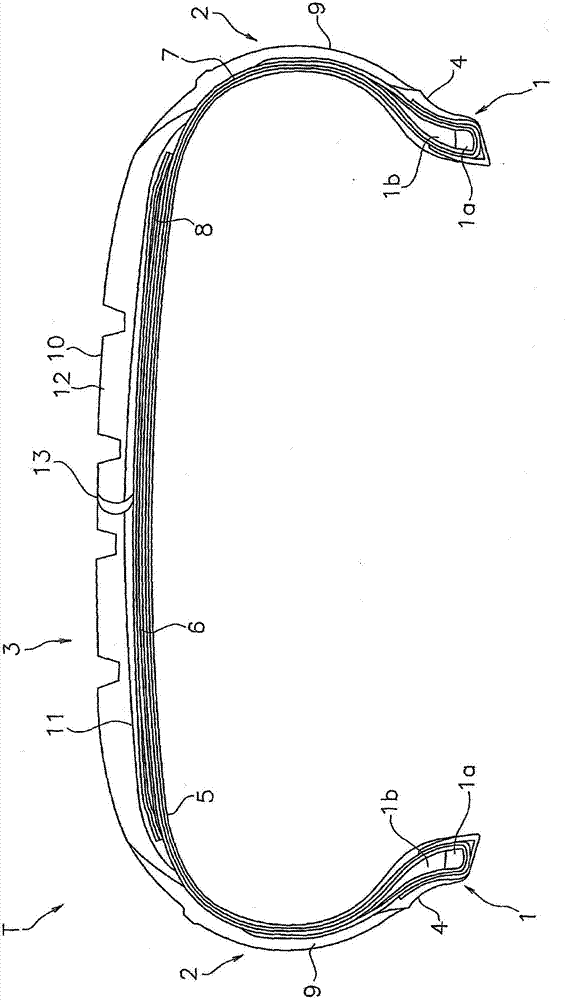

Pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire parts, tire tread/tread pattern, rolling resistance optimization, etc., can solve the problems of reducing base volume, damage, and easy damage, so as to reduce rolling resistance and ensure Steering stability and the effect of maintaining rigid balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

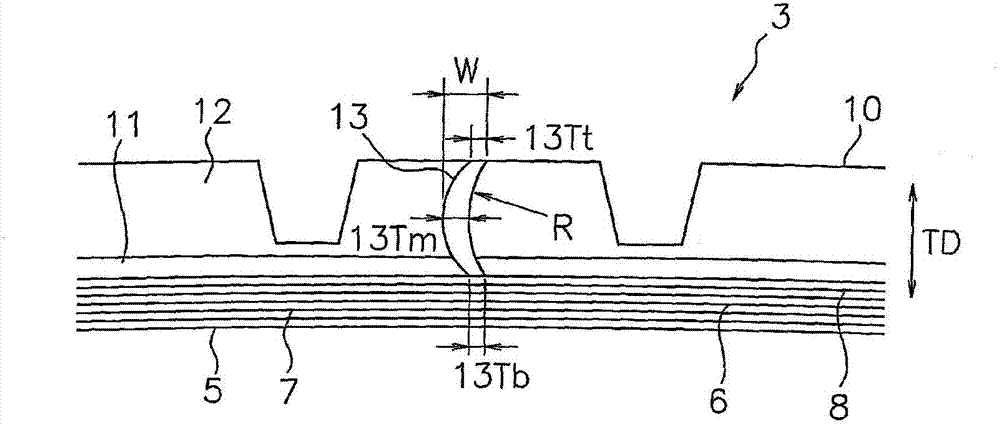

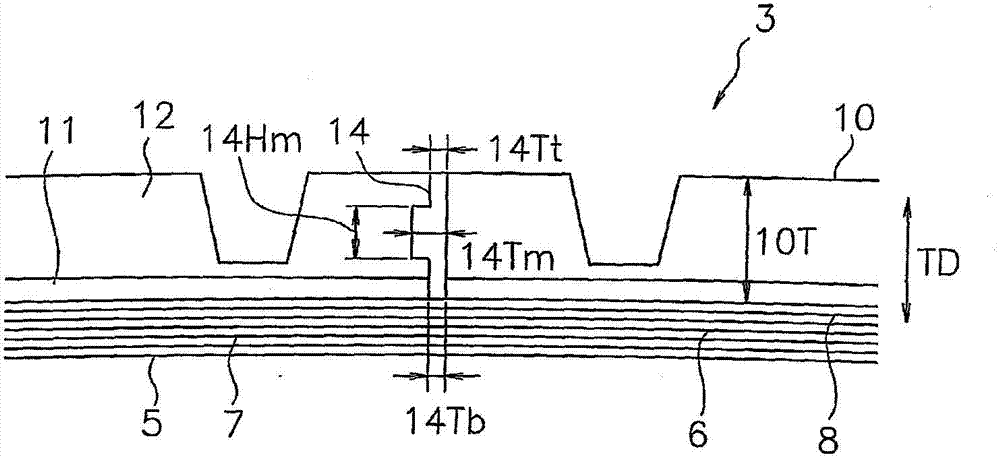

[0057] (1) In the above-mentioned embodiment, an example in which the conductive part is substantially crescent-shaped in the tire meridian section is shown, but it is not limited thereto. For example, it may be as follows: image 3 The conductive part 14 of the transverse T shape. In this conductive portion 14 , the thickness of the center portion in the thickness direction TD of the tread rubber 10 is relatively large, and the thickness of both ends of the tread rubber 10 in the thickness direction TD is relatively small.

[0058] exist image 3 In an example, the thickness 14Tm of the conductive part 14 at the center in the thickness direction TD is set to 0.6-1.5 mm, for example. In addition, the thickness 14Tt of the conductive portion 14 on the ground surface is, for example, 0.1-0.9 mm, and the thickness 14Tb of the conductive portion 14 on the bottom surface of the tread rubber 10 is, for example, 0.1-0.4 mm. In this shape, the height 14Hm of the thick portion of the...

Embodiment

[0062] Hereinafter, examples showing the configuration and effects of the present invention will be described. Each performance evaluation of the tire was performed as follows.

[0063] (1) Handling stability

[0064] Tires were mounted on an actual vehicle (1.5L class Nissan sedan), and the vehicle was driven straight or turning under the specified air pressure with the load of a single driver, and evaluated by the driver's sensory test. The results of the conventional example were evaluated as an index of 100, and a larger value indicates better steering stability.

[0065] (2) Rolling resistance

[0066] Based on the international standard ISO28580 (JISD4234), the rolling resistance at a speed of 80km / h was measured, and the reciprocal was calculated. The results of the conventional examples were evaluated as an index of 100, and a larger value indicates better rolling resistance.

[0067] (3) Wet braking performance

[0068] Install the tires on the above actual vehic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com