A tempered glass anti-glare board applied to road traffic and its production process

A tempered glass, road traffic technology, applied in the direction of glass/slag layered products, layered products, chemical instruments and methods, etc., can solve the problems of staggering daily maintenance costs, environmental pollution, liver damage, etc., and achieve high firmness , strong resistance to ultraviolet radiation, long-term effect of anti-exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

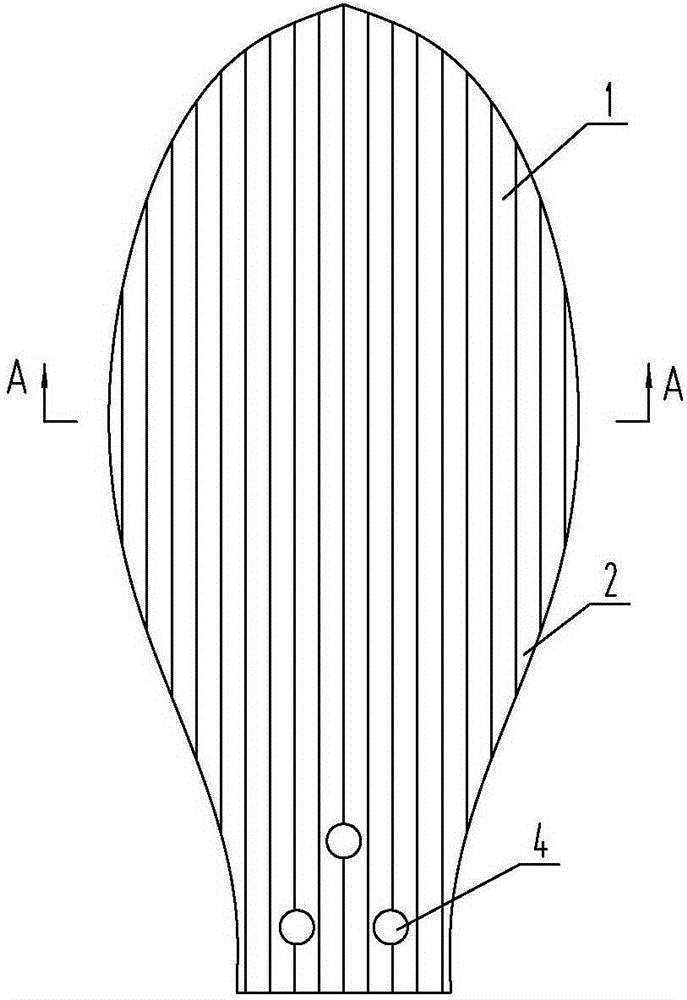

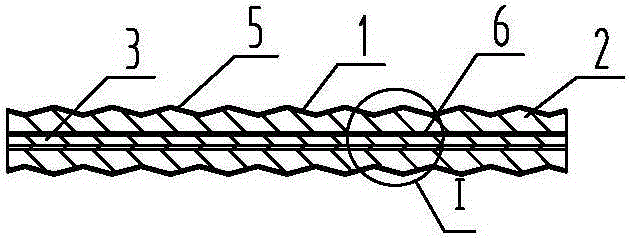

[0031] Such as figure 1 , figure 2 with image 3 As shown, the plate body of the present invention is formed by laminating two tempered glass plates 2 with a thickness of 5 mm, and an adhesive layer 3 with a thickness of 1.5 mm is interposed between the two tempered glass plates 2. The tempered glass is ordinary glass after A kind of glass with compressive stress formed by tempering. The tempering treatment improves the bearing capacity of the glass itself, and can withstand rapid temperature changes in the range of 200°C in harsh environments. It has good mechanical properties and thermal shock resistance; when the glass is subjected to external forces When the stress of the surface layer is greater than the damage, the fragments will form countless small obtuse particles, which is called a kind of safety glass; and the glass itself does not contain toxic elements such as lead and chromium, and the resources can be recycled and reused, which is in line with the current advo...

Embodiment 2

[0042] The difference between this example and Example 1 is that in the production process, the drying temperature is 100°C, the drying time is 24 hours, the tempering temperature is 550°C, the heating temperature of the electric heating device is 180°C, and the rest are the same as in the example one.

Embodiment 3

[0044] The difference between this example and Example 1 is that in the production process, the drying temperature is 260°C, the drying time is 6 hours, the tempering temperature is 850°C, the heating temperature of the electric heating device is 260°C, and the rest are the same as in the example one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com