Coating process

A coating process and coating technology, applied in the direction of coating, the device for coating liquid on the surface, the pretreatment of the surface, etc., can solve the problems of poor coating, high environmental pollution, high energy consumption, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

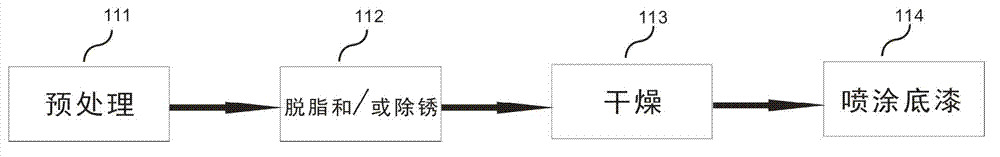

[0031] Such as figure 1 As shown, the coating process of the present invention includes the following steps. Step 111, pretreat the base material; Step 112, degrease and / or derust; Step 113, dry; Step 114, spray primer.

[0032] The process of the present invention carries out pretreatment to base material earlier, mainly is:

[0033] 1. Classify the base materials (aluminum, steel, fiber, fiberglass, etc.) to determine the pretreatment method;

[0034] 2. Judging the corrosion level and derusting level of steel (up to st3 level);

[0035] 3. Visually inspect the weight of the oil stain on the substrate, so as to take the corresponding oil stain cleaning agent;

[0036] 4. Remove dust, welding slag, sundries, etc. on the painted parts.

[0037] The purpose of treatment before painting is to remove grease, oil stains, corrosion products, residual impurities, etc. on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com