Half-feed-type harvesting machine with rubber strip teeth

A semi-feeding and harvesting machine technology, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of unfavorable harvester machine design, large amount of steel materials, and long transportation distance of rice ears, etc., to achieve saving The effects of manpower and material resources, reduction of steel consumption, and reduction of transportation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

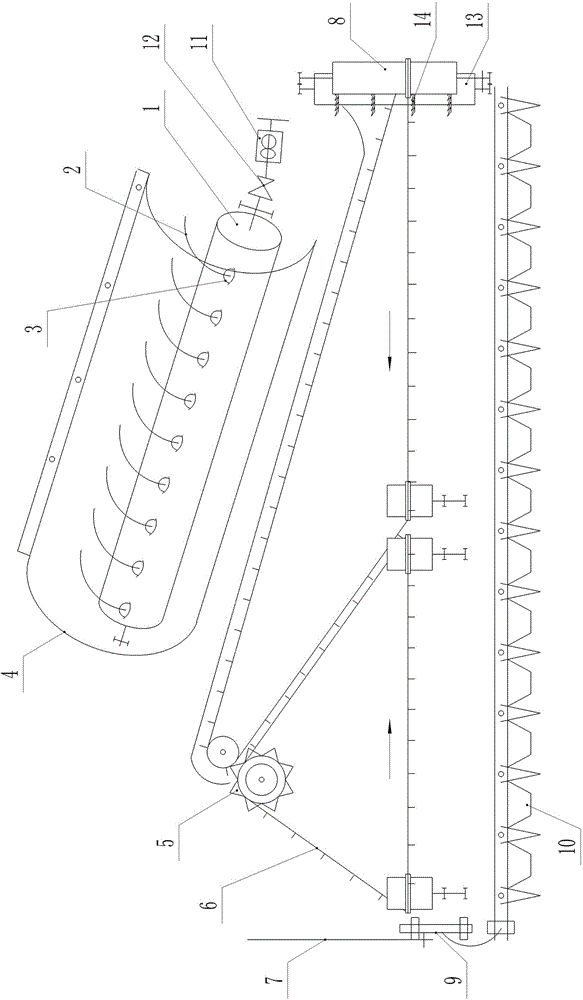

[0019] Reference figure 1 , A semi-feeding harvester with rubber splines, comprising a threshing gear 2 arranged on the threshing drum 1 and a rice stalk conveyor chain in the rice delivery mechanism. The threshing gear 2 is a rubber stalk tooth, and the rice stalk conveyor chain The arrangement structure is triangular. The structure of the rice stalk conveyor chain is assembled by a conveyor chain 6 with a grass sprocket 5 and two sprockets 8 arranged in a triangle. The arrow in the figure indicates the direction of movement of the rice stalk conveyor chain, and the threshing drum 1 is set in one of them. One side of the rice stalk conveyor chain arranged in a triangular shape reduces the linear distance of the threshing process and reduces the transport distance of the rice ears. The threshing process can be completed with a short linear distance, and the whole machine can be designed more compactly.

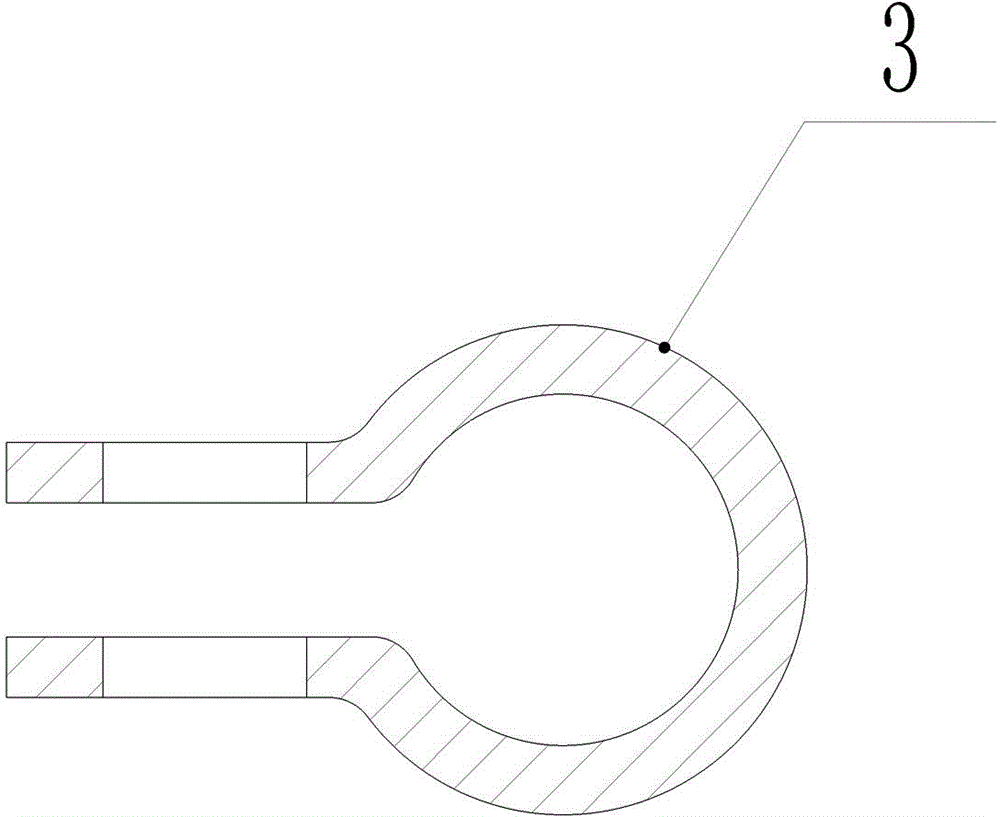

[0020] The rubber teeth are C-shaped triangle belts.

[0021] The teeth of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com