Ultrahigh pressure water jet coal sample cutting preparation machine

An ultra-high pressure, water jet technology, applied in the preparation of test samples, sampling devices, etc., can solve the problems of pulverized coal environmental pollution, low efficiency, heating and combustion, etc., and achieve the effect of improving quality, stable operation, and preventing excessive waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

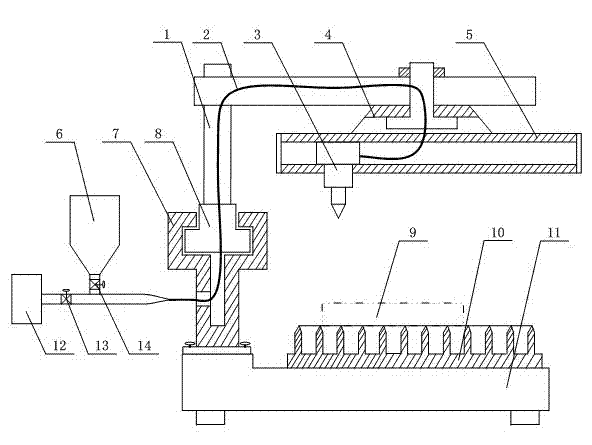

[0013] exist figure 1 Among them, the ultra-high pressure water jet cutting coal sample preparation machine includes a Y-direction lifting arm 1, a water supply and sand supply pipeline 2, a cutting machine 3, a disc-shaped fixed arm 4, an X-direction guide arm 5, a sand supply device 6, and a support arm 7 , Z guide rail arm 8, tray 10, workbench 11, ultrahigh pressure water pump 12, valve I13 and valve II14; the ultrahigh pressure water jet cutting coal sample preparation machine is provided with a square workbench 11, the The upper part is provided with a grid-shaped tray 10, and one side of the workbench 11 is provided with a vertical support arm 7. The upper end of the support arm 7 is provided with a dovetail groove, and a dovetail-shaped Z guide rail arm 8 is matched in the dovetail groove. The top of the Z guide rail arm 8 is connected with the Y-direction elevating arm 1 that can be lifted up and down, and one side of the Y-direction elevating arm 1 is laterally bent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com