Scroll compressor with axially flexible seal

A scroll compressor, axial technology, applied in the direction of rotary piston machinery, sealing device of piston pump, mechanical equipment, etc., can solve the problem that low pressure scroll compressor cannot be applied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

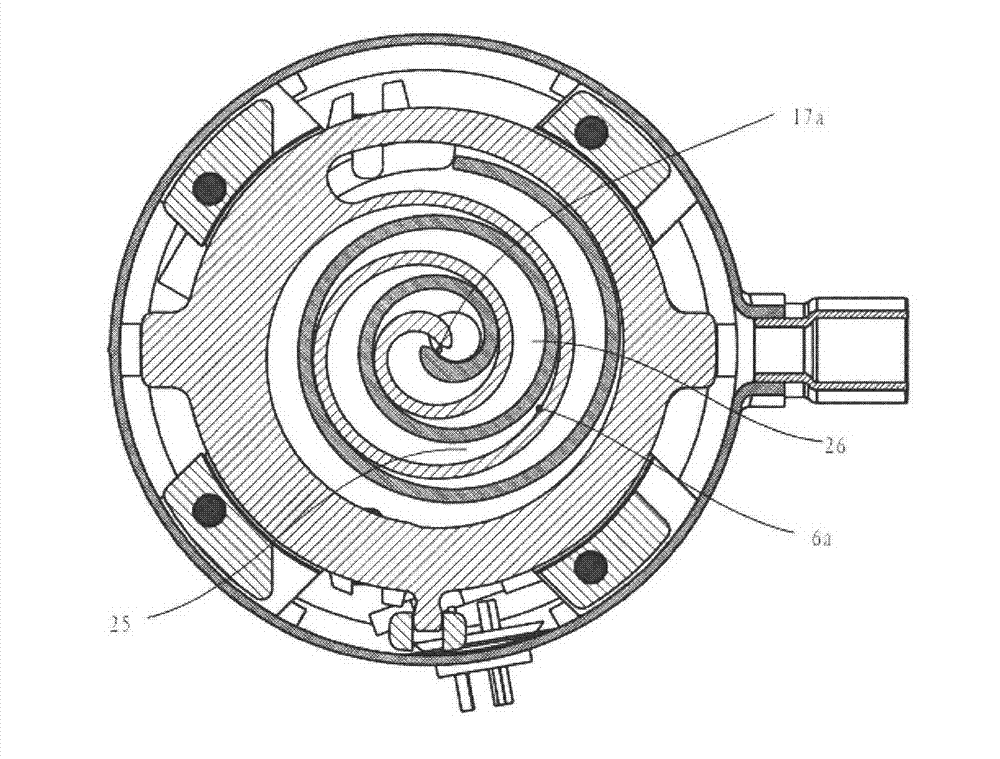

[0012] A scroll compressor, comprising a motor 12, a crankshaft 13, a movable scroll 3, a fixed scroll 2, an Oldham slip ring 4, a support frame 16, a casing 14, the motor 12, a crankshaft 13, and a movable scroll 3 , the fixed scroll 2, the Oldham slip ring 4, and the support frame 16 are all on the low-pressure side connected to the compressor suction port 5, the fixed scroll 2 is fixed on the support frame 16, and the movable scroll 3 is placed between the fixed scroll 2 and the Between the supporting frame 16, there is a certain gap in the axial direction to realize the axial floating of the movable scroll 3, and the movable scroll 3 and the fixed scroll 2 are coupled through the Oldham slip ring 4 to form at least one pair of relatively closed compression Cavities 25 and 26 are characterized in that a first sealed cavity 8 and a second sealed cavity 10 are provided between the back of the movable scroll 3 and the end surface of the support frame 16, which are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com