Tension balancer

An equalizing device and tension technology, applied in textiles and papermaking, knitting, warp knitting, etc., can solve the problems of cotton yarn tension fluctuation and cotton yarn easy to break, reduce tension fluctuation, reduce cotton yarn breakage, improve production efficiency and product quality quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

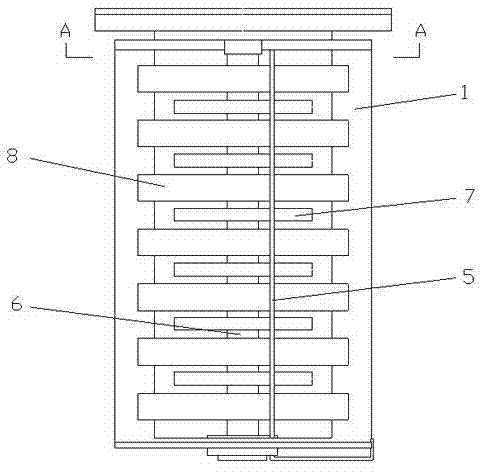

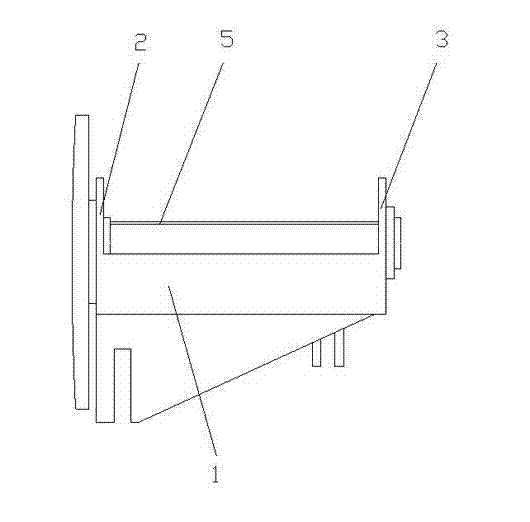

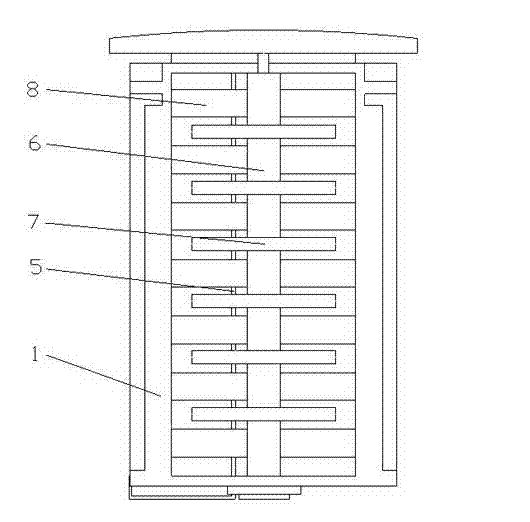

[0019] see figure 1 , a tension equalization device, comprising: a yarn guide support 1, the yarn guide support 1 has a first side plate 2 and a second side plate 3, the first side plate 2 and the second side plate 3 correspond to A yarn guide hole 4 is provided, and the yarn guide support 1 is provided with a yarn guide rod 5, one end of the yarn guide rod 5 passes through the second side plate 3 and is in contact with the first side plate 2, and the other end is arranged on the second side plate 3. On the two side plates 3, a guide rail 6 is arranged on the yarn guide support 1, a plurality of yarn guide rings 7 are arranged on the guide rail 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com