Control method of draught fan for dry dust removal of converter gas

A technology of dry dust removal and converter gas, applied in the manufacture of converters, etc., can solve the problems of overshoot and response time, large fluctuations of converter flue gas, parasitic tremors, etc., to ensure recovery, good effect, high The effect of dynamic response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

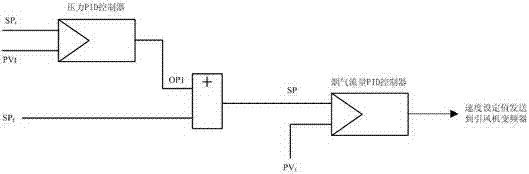

[0022] figure 1 It is a schematic structural diagram of the control system according to an embodiment of the present invention. The solid line in the figure indicates the transmission direction of the flue gas. The flue gas enters the dust collector through the vaporization cooling flue 6 from the furnace mouth of the converter 1 and is released from the dust collector. Fan 5 goes to let off the chimney. On the basis of the original system, a differential pressure measurement device 2 is installed at the furnace mouth hood of the converter to detect the process value of the differential pressure at the converter furnace mouth; a flue gas flow measurement device 3 is installed at the outlet of the dust collector to detect the flue gas The flow process value; the dotted line in the figure represents the logical relationship of control, the process value collected by the differential pressure measuring device 2 and the flue gas flow measuring device 3 is processed by the controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com