Device and method for performing pyrolysis on solid fuel and performing reductive coupling on iron ore

A technology of solid fuel and iron ore, which is applied in iron ore reduction and fuel chemical industry, can solve problems such as restrictions and environmental pollution, and achieve the effect of enhancing contact degree, reducing cost and reducing dust content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

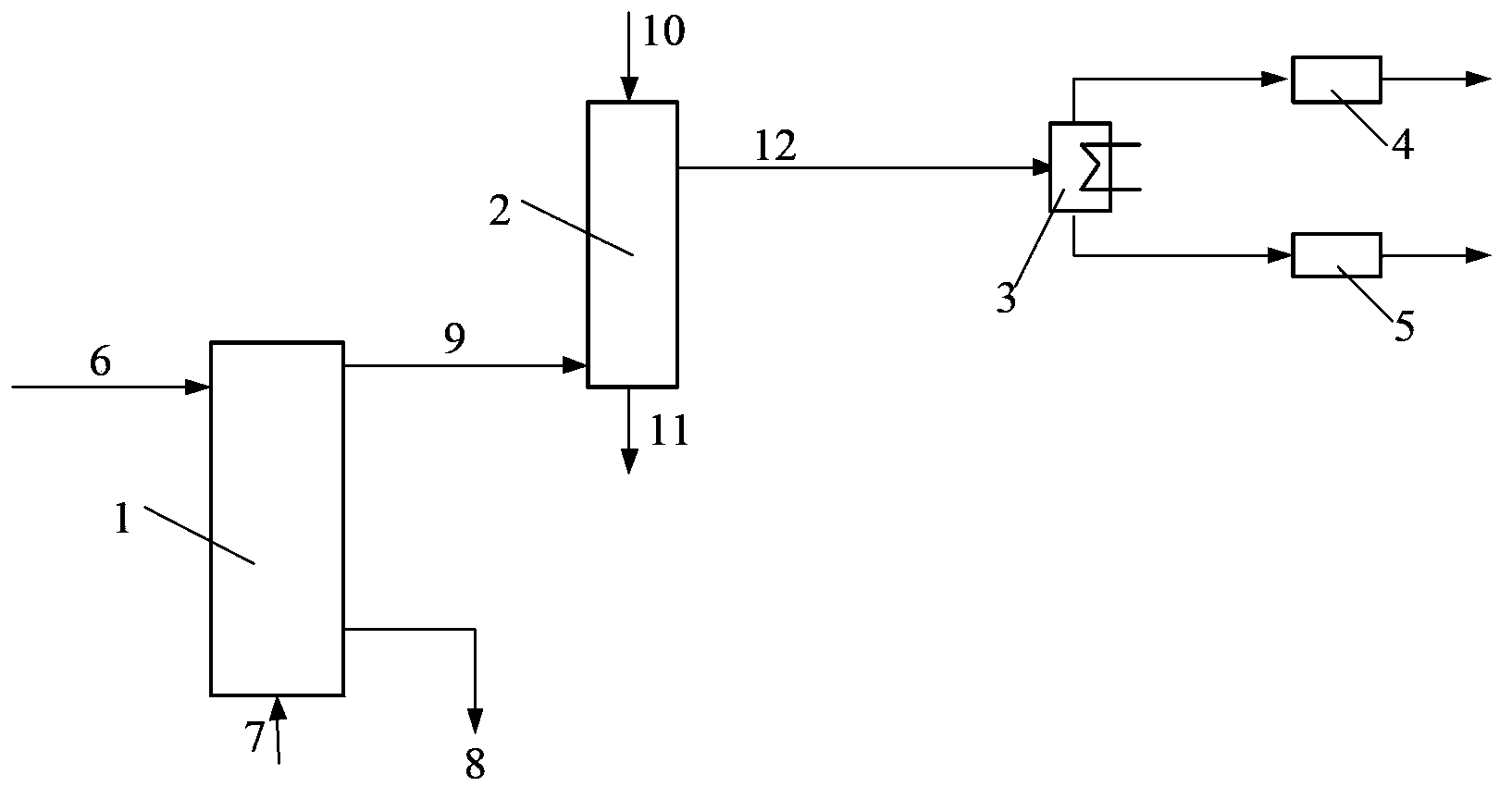

[0045] The lignite raw material is fed into the fluidized bed pyrolysis reactor from the solid fuel feed pipe, and under the action of the carrier gas nitrogen introduced from the carrier gas inlet pipe, pyrolysis occurs at a pressure of 0.1Mpa and a temperature of 650°C. Pyrolysis oil, pyrolysis gas and pyrolysis semi-coke are obtained, and the pyrolysis semi-coke is discharged from the pyrolysis semi-coke discharge pipe to obtain semi-coke products; the discharged pyrolysis oil and pyrolysis gas are discharged from the countercurrent moving bed reactor The lower part enters and contacts with the iron ore fed by the iron ore feeding pipe in countercurrent, and the heavy components in the pyrolysis oil continue to be cracked under the action of iron ore at 950°C to generate light tar, while the iron ore The rock is reduced to elemental iron and discharged from the elemental iron discharge pipe at the bottom of the reactor; the light tar and pyrolysis gas produced by cracking ar...

Embodiment 2

[0047] In this embodiment, the same experimental method as in Example 1 is adopted, the difference is that the pyrolysis reactor adopts a fixed bed reactor; the pressure is 6MPa, and the carrier gas is a hydrogen-rich reducing gas; the temperature at which the pyrolysis reaction occurs in the fixed bed reactor The temperature of the countercurrent moving bed reactor is 800°C.

Embodiment 3

[0049] In this embodiment, the same experimental method as in Example 1 is adopted, the difference is that the pyrolysis reactor is a moving bed reactor; the solid fuel is Jilin Huadian oil shale; the carrier gas is hydrogen; the pyrolysis reaction occurs in the moving bed reactor The temperature is 500°C and the pressure is 1MPa; the temperature of the countercurrent moving bed reactor is 750°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com