An improved plastic material based on pp plastic

A plastic material and basic technology, applied in the field of improved plastic materials, can solve the problems of easy aging, poor low temperature resistance, PP plastic can not be used, etc., to achieve the effect of improved aging resistance and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

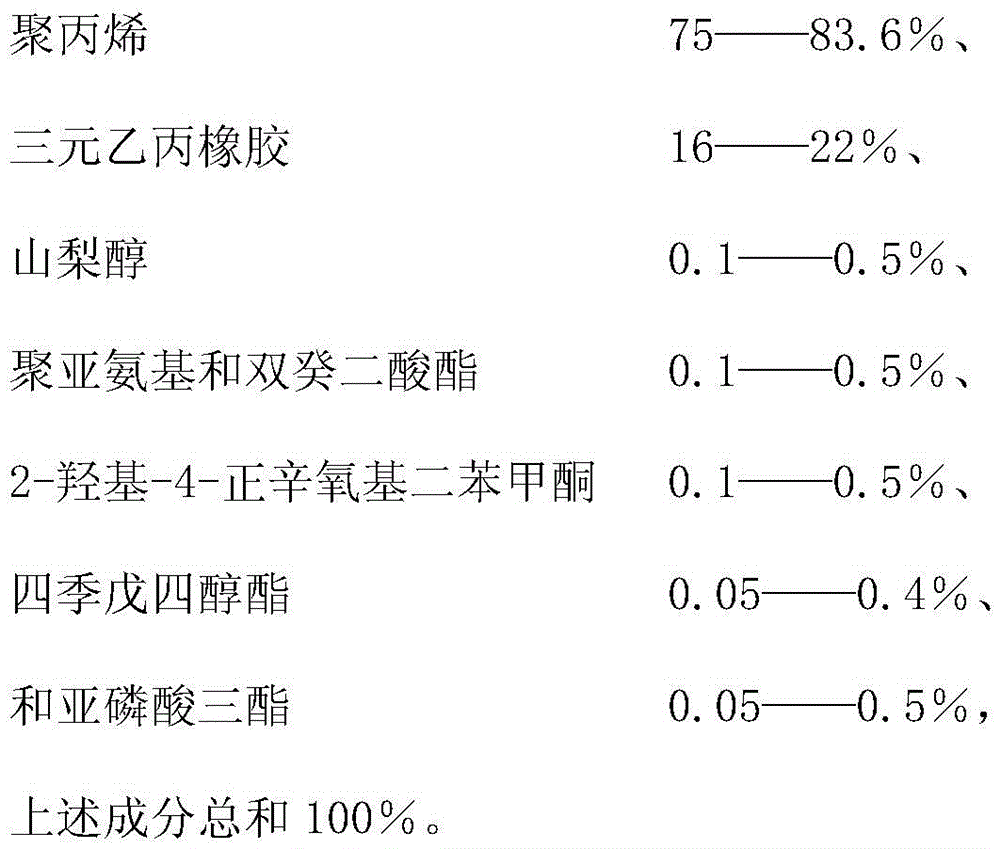

Method used

Image

Examples

Embodiment 1

[0017] Reclaimer:

[0018] PP-M700R (polypropylene) 75 kg,

[0019] EPDM (ethylene propylene diene monomer) 22 kg,

[0020] Anti-impact agent Z-3 (sorbitol) 1 kg,

[0021] Light Stabilizer 791 (Polyimide and Bisebacate) 1 kg,

[0022] UV absorber UV531 (2-hydroxyl-4-n-octyloxybenzophenone) 0.5 kg,

[0023] Antioxidant 1010 (tetraerythritol ester) 0.25 kilograms,

[0024] And antioxidant 168 (phosphite triester) 0.25 kilogram,

[0025] The sum of the above ingredients is 100 kg.

[0026] The above-mentioned materials are weighed according to the formula and pre-mixed into a mixture with a medium-speed mixer. The mixture passes through a shallow groove twin-screw mixing extrusion granulation unit (built-in special screw for PP modification, and the screw is divided into: feeding section, mixing section , Exhaust section, Extrusion section. The difference from ordinary screw is that a left-handed screw block is added before and after the mixing section to increase the mixin...

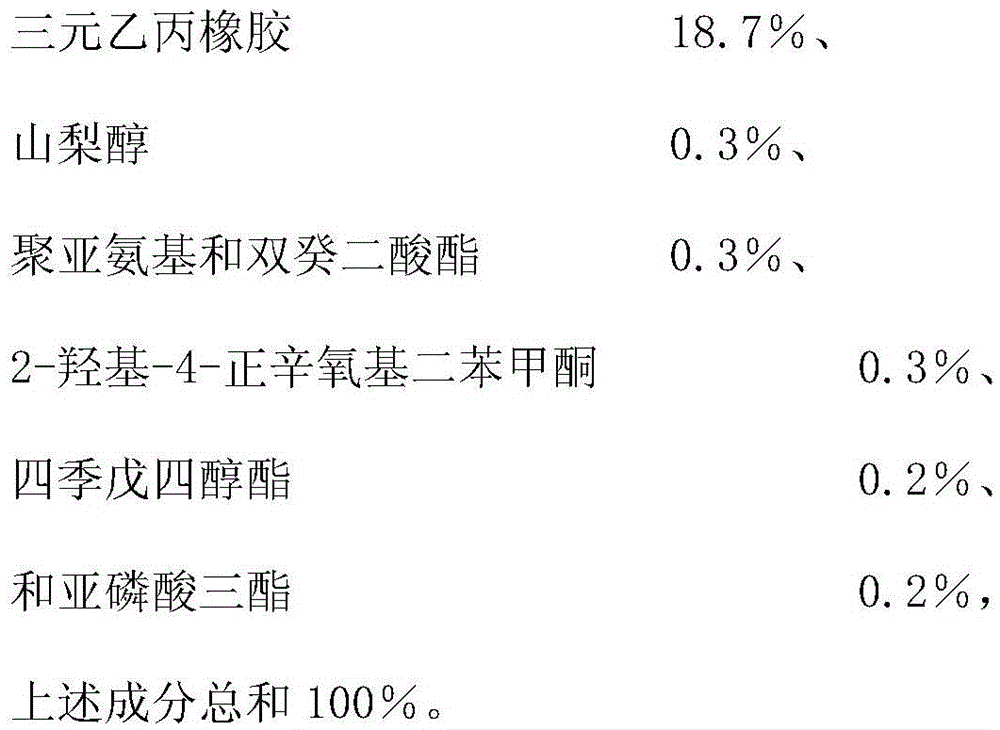

Embodiment 2

[0036] Reclaimer:

[0037] PP-M700R (polypropylene) 80 kg,

[0038] EPDM (ethylene propylene diene monomer) 18.7 kg,

[0039] Anti-impact agent Z-3 (sorbitol) 0.3 kg,

[0040] Light stabilizer 791 (polyimide and bis-sebacate) 0.3 kg,

[0041] UV absorber UV531 (2-hydroxyl-4-n-octyloxybenzophenone) 0.3 kg,

[0042] Antioxidant 1010 (tetraerythritol ester) 0.2 kilogram,

[0043] And antioxidant 168 (phosphite triester) 0.2 kilogram,

[0044] The sum of the above ingredients is 100%.

[0045] The preparation method is the same, and the parameters are the same during injection molding.

Embodiment 3

[0047] Reclaimer:

[0048] PP-M700R (polypropylene) 83.6 kg,

[0049] EPDM (ethylene propylene diene monomer) 16 kg,

[0050] Anti-impact agent Z-3 (sorbitol) 0.1 kg,

[0051] Light stabilizer 791 (polyimide and bis-sebacate) 0.1 kg,

[0052] Ultraviolet absorber UV531 (2-hydroxyl-4-n-octyloxybenzophenone) 0.1 kilogram,

[0053] Antioxidant 1010 (tetraerythritol ester) 0.05 kilogram,

[0054] And antioxidant 168 (phosphite triester) 0.05 kilogram,

[0055] The sum of the above ingredients is 100%.

[0056] The preparation method is the same, and the parameters are the same during injection molding.

[0057] Performance characteristics:

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com