Non-envelope controlled-release synergistic nitrogen fertilizer and preparation method thereof

A slow-release, non-encapsulated technology, applied in fertilization devices, fertilizer mixtures, agricultural gas emission reduction, etc., can solve the problem of short service life of granulator scrapers and orifice nets, and affect the adsorption of γ-polyglutamic acid Efficacy, affecting production continuity and efficiency, etc., to achieve the effect of improving soil water and fertilizer retention capacity, improving fertilizer utilization rate, and ensuring slow-release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Take the preparation of 100kg non-coated slow-release synergistic nitrogen fertilizer as an example, 1kg of γ-polyglutamic acid, 1.0kg of zinc sulfate as an auxiliary agent, 0.5kg of thiourea as an auxiliary agent, and 1.5kg of calcium chloride as an auxiliary agent , 0.3kg of ferrous sulfate as an auxiliary agent, and the balance is ammonium chloride as a basic component. The preparation method is as follows:

[0042] 1) Preparation of γ-polyglutamic acid mixture: Weigh γ-polyglutamic acid and additives in proportion, and mix to obtain γ-polyglutamic acid mixture.

[0043] 2) Mix the powdery basic components with the γ-polyglutamic acid mixture obtained in step 1) (stir mixing or spray mixing), roll into a sheet by a roller press, and cool down to normal temperature.

[0044] 3) Use a special impact granulator for granulation.

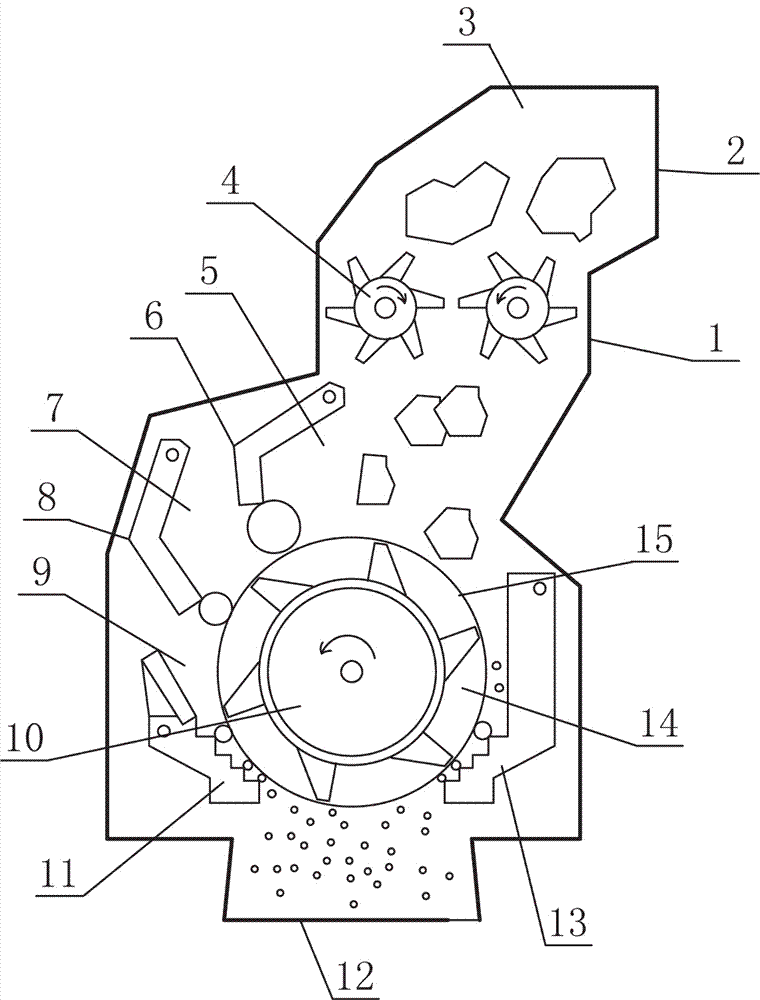

[0045] like figure 1 , The special impact granulator of the present invention includes a container-shaped casing 1 with a feed inlet 2 at t...

Embodiment 2

[0064] Take the preparation of 100kg non-coated slow-release synergistic nitrogen fertilizer as an example, 0.8kg of γ-polyglutamic acid, 1.2kg of copper sulfate as auxiliary agent, 0.3kg of dicyandiamide as auxiliary agent, and calcium chloride as auxiliary agent 0.9kg, 0.3kg of acephate as auxiliary agent, and the balance is ammonium nitrate as basic component. The preparation method is the same as in Example 1. The preparation method is the same as in Example 1.

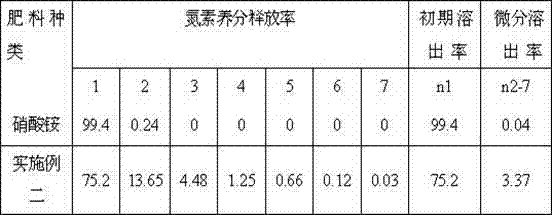

[0065] Table 2-1 and 2-2 show the comparative experimental data of the slow-release effect and yield-increasing effect of the non-coated slow-release synergistic nitrogen fertilizer prepared in this example.

[0066] Table 2-1: Hydrostatic release rate test at 25°C

[0067]

[0068] Experimental method: Weigh about 10.00 g of ordinary ammonium nitrate and the sample of Example 2, put them into a pouch made of 100-mesh nylon gauze, seal the pouch and put it into a 300ml plastic bottle, add 250ml of distilled w...

Embodiment 3

[0074] Take the preparation of 100kg non-coated slow-release synergistic nitrogen fertilizer as an example, 1.5kg of γ-polyglutamic acid, 0.6kg of calcium carbonate as an auxiliary agent, 0.6kg of cyanohydrin as an auxiliary agent, and 0.5 kg of calcium chloride as an auxiliary agent kg, 0.1 kg of boric acid as an auxiliary agent, and the balance as urea as a basic component. The preparation method is the same as in Example 1.

[0075] Table 3-1 and 3-2 show the comparative experimental data of the slow-release effect and yield-increasing effect of the non-coated slow-release synergistic nitrogen fertilizer prepared in this example.

[0076] Table 3-1: Hydrostatic release rate test at 25°C

[0077]

[0078] Experimental method: Weigh about 10.00 g of ordinary urea and the sample of Example 3, put them into a pouch made of 100-mesh nylon gauze, seal the pouch and put it into a 300ml plastic bottle, add 250ml of distilled water, seal it with a cap, Place them in a biochemical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com