Flameproof speed sensor used for belt-broken protective device of belt conveyor

A belt conveyor and speed sensor technology, applied in conveyor control devices, conveyor objects, measuring devices, etc., can solve the problem that the speed signal is not unique, the belt speed sensor cannot be detected by the broken belt signal, and the broken belt protection device Malfunction and other problems, to achieve the effect of simple maintenance, shortened processing time, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

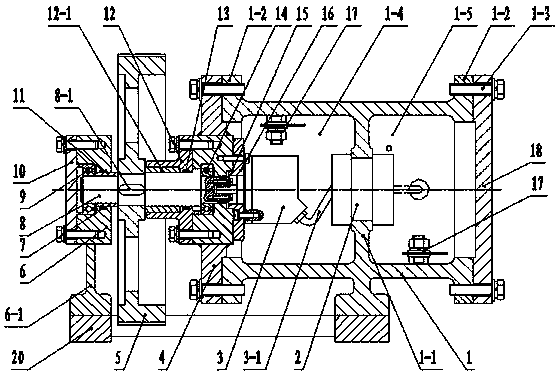

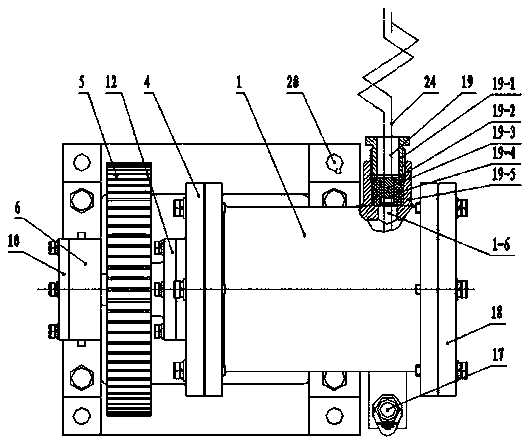

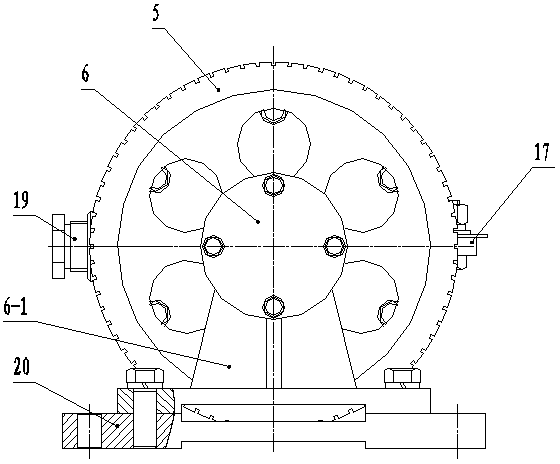

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown: a flameproof speed sensor for a broken belt protection device for a belt conveyor, which includes: a base 20, a bearing seat II6, a speed measuring wheel 5, a transmission shaft 8, a bearing cover 12, a bearing seat I4, and an explosion-proof housing 1. Encoder 3, flameproof terminal block 2 and wiring cavity cover 18. The bearing seat II6 is connected to the bracket 6-1; the explosion-proof housing 1 and the bracket 6-1 are fixed on the base 20, and the base 20 is installed on the belt conveyor frame 25 through the sensor bracket 21; A preload spring 22 is set between the base 20 and the sensor bracket 21; the speed measuring wheel 5 is in contact with the belt 23 on the conveyor, and the belt 23 on the conveyor drives the speed measuring wheel 5 to rotate, and the rotational speed value of the speed measuring wheel 5 is transmitted to the Encoder 3 on. The pulse value output by the encoder 3 is sent to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com