Shaftless screw conveyor

A shaftless screw conveying and shaftless screw technology, applied in the field of shaftless screw conveyors, can solve the problems of unreasonable force, deformation and fracture, easy jamming, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

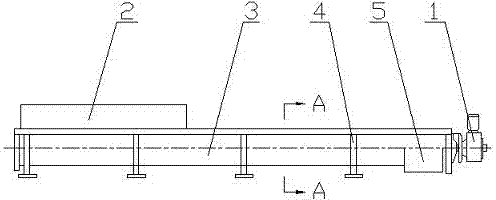

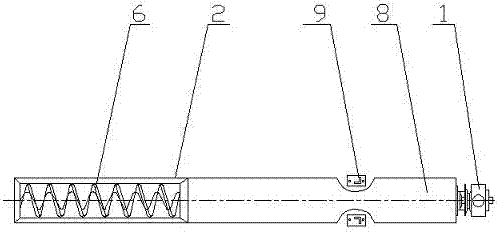

[0022] The shaftless screw conveyor consists of a driving device 1, a head assembly, a casing 3, a shaftless screw body 6, a tank liner 7, an inlet 2, an outlet 5, a cover 8, and a base.

[0023] exist figure 1 Among them, the driving device 1 is arranged at the end of the discharge port, and the driving device is connected with the tail end of the shaftless helical body, so that the shaftless helical body 6 is in a tensioned state during operation. The driving device 1 includes a motor and a reducer, and the reducer adopts a cycloidal pin wheel reducer or a shaft-mounted hardened gear reducer.

[0024] The head assembly is equipped with a thrust bearing, which can withstand the axial force generated when conveying materials.

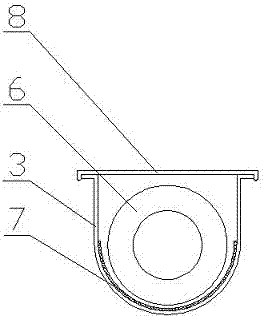

[0025] exist image 3 Among them, the casing 3 is U-shaped and made of stainless steel, carbon steel or glass fiber reinforced plastic. The top of the casing 3 is provided with a rainproof type cover 8 .

[0026] The shaftless spiral body 6 is made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com