Composite material and preparation method thereof and electronic device with composite material

A technology of composite materials and prefabricated parts, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as single visual effect and tactile feeling, long time, large manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a method for preparing a composite material, comprising: a) soaking the first material with fiber characteristics in the resin composition to obtain a prepreg;

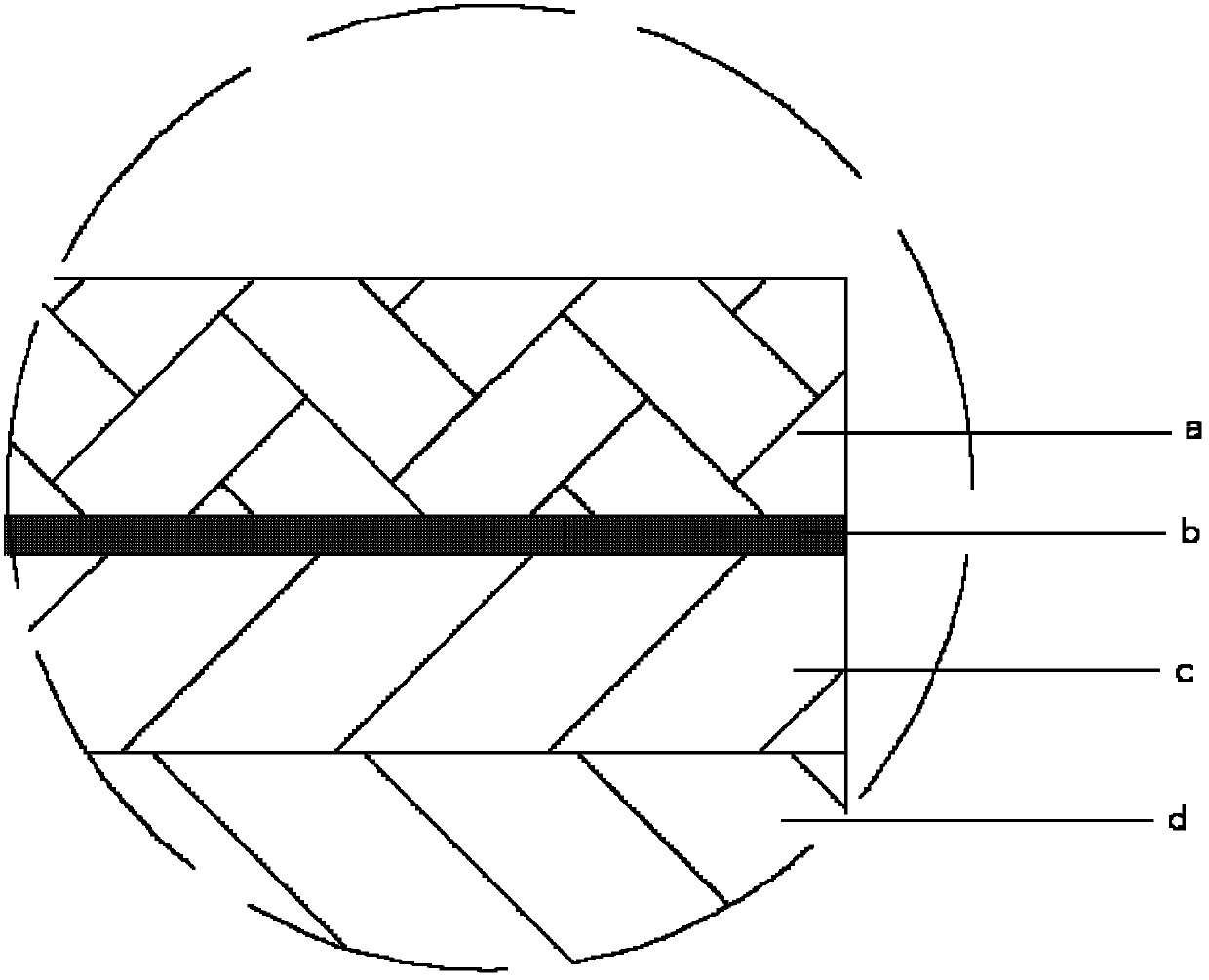

[0045] b) placing at least one prepreg and at least one preform formed of a second material with metallic properties in a mold for hot pressing to obtain the composite material; the linear thermal expansion coefficient of the prepreg is the same as that of the prepreg wherein the prepreg forms the support layer; and the preform forms the facing layer.

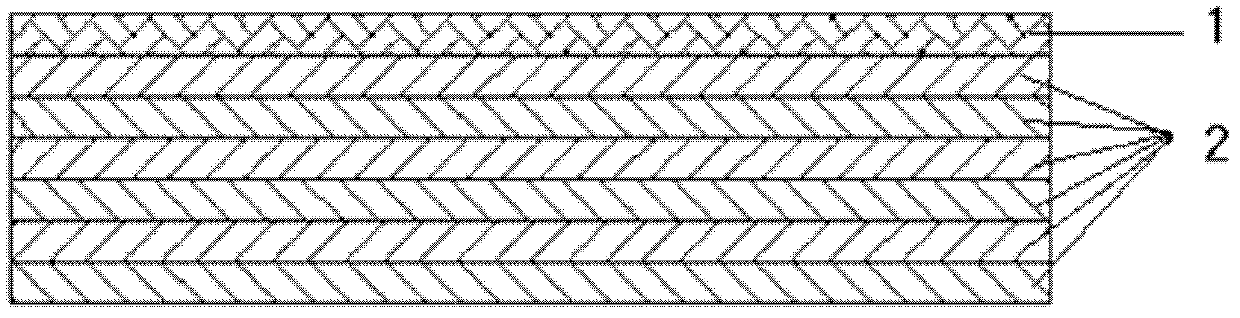

[0046] Compared with the prior art, the composite material provided by the present invention includes a support layer and a surface layer, and the support layer is formed by a first material soaked in a resin composition, and the first material is preferably carbon fiber. According to the present invention, The carbon fiber is preferably a prepreg sheet obtained by immersing continuous carbon fiber strands in epoxy resin and t...

Embodiment 3

[0055] Take 8 epoxy resin pre-impregnated carbon fiber sheets with a thickness of 0.1 mm, with a size of 1 m × 1 m. The prepreg carbon fiber sheet stacks are placed with the edges aligned. Coat the surface of the uppermost carbon fiber sheet with thermosetting epoxy resin adhesive to form a coating film, and then take an aluminum alloy foil of the same specification with a thickness of 0.1 mm and place it on the thermosetting epoxy resin adhesive coating film. Thereby, a preform is obtained. The word lenovo is etched on the surface of the aluminum alloy foil.

[0056] The preform was placed on the lower pressure film of the vacuum hot press, the mold was closed but no pressure was applied, and then a vacuum was applied to make the vacuum degree reach 1 kPa, the temperature was raised to 130 ° C, hot pressing for 15 minutes, and pressure holding for 5 minutes Then take out the composite material.

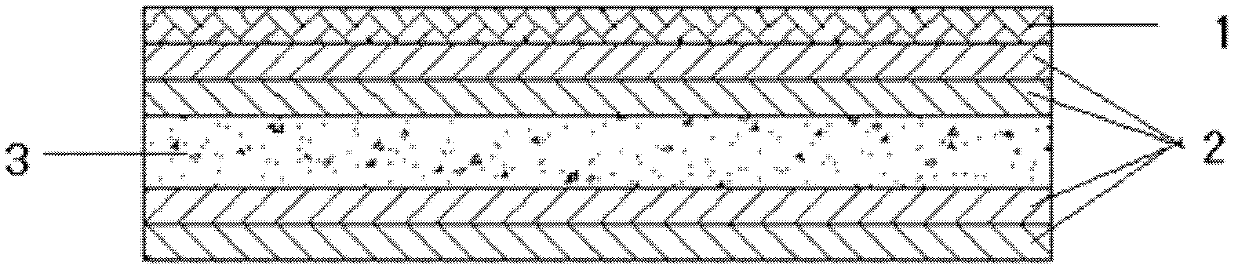

Embodiment 4

[0058] Take 4 epoxy resin prepreg carbon fiber sheets with a thickness of 0.1 mm, and the specifications are 1 m × 1 m. A piece of foamed polyethylene sheet with a thickness of 0.5mm and a specification of 1m × 1m. The pre-impregnated carbon fiber sheet and the foamed polyethylene sheet such as figure 2 Stacked in the order shown, edge-to-edge. Coat the surface of the uppermost carbon fiber sheet with thermosetting epoxy resin adhesive to form a coating film, and then take an aluminum alloy foil of the same specification with a thickness of 0.1 mm and place it on the thermosetting epoxy resin adhesive coating film. Thereby, a preform is obtained. The word lenovo is etched on the surface of the aluminum alloy foil.

[0059] The pre-pressed part was placed on the lower pressure film of a vacuum hot-pressing machine, evacuated to make the vacuum degree reach 5 kPa, the temperature was raised to 130° C., hot-pressed for 15 minutes, and the composite material was taken out after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface thickness | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

| Coefficient of linear thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com