ELID (electrolytic in-process dressing) ultrasonic honing device

A honing and ultrasonic technology, applied in the direction of honing machine tools, honing tools, metal processing equipment, etc., can solve the problems of poor precision, stop sharpening, low honing efficiency, etc., achieve good results, slow down honing vibration, and meet high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

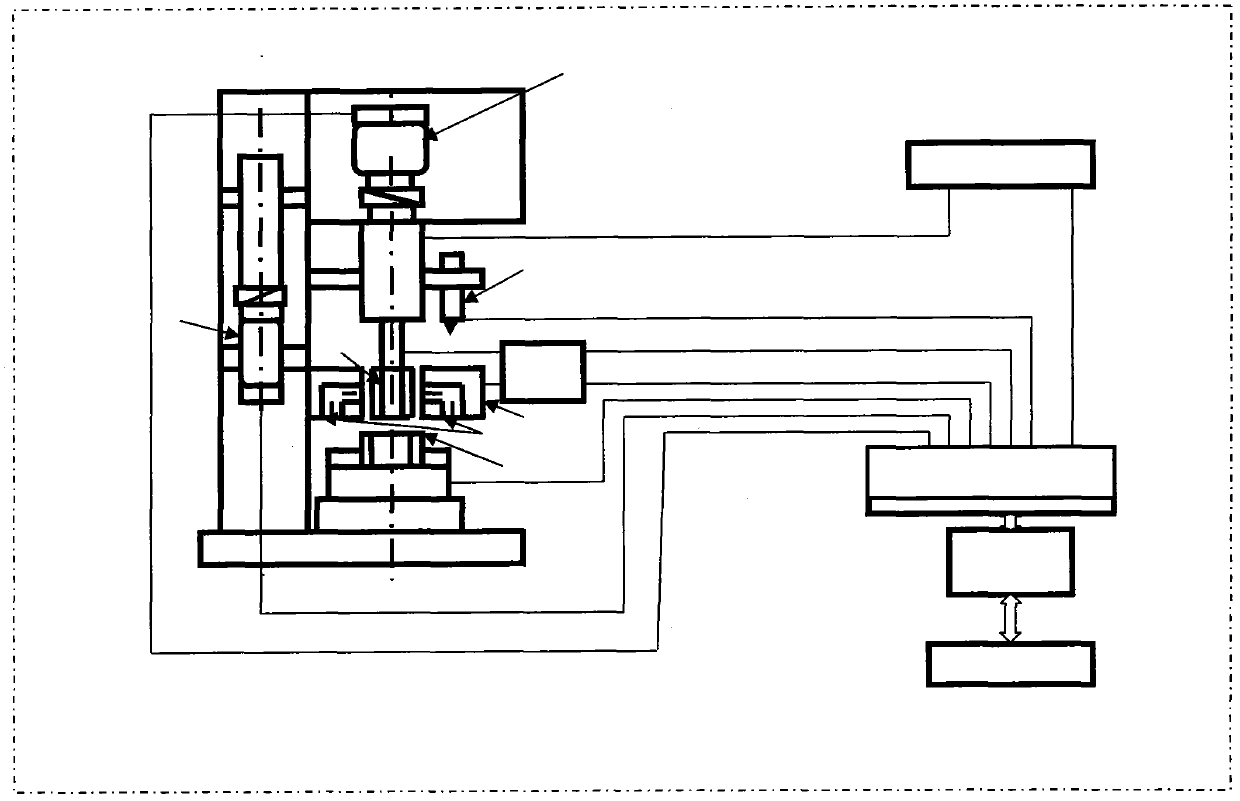

[0051] Such as figure 1 As shown, this embodiment aims at high-speed, high-efficiency, and high-precision honing of cylinder liners, and solves the problems of low efficiency and poor precision of traditional honing. Especially when honing cylinder liners of hard and brittle materials such as ceramics and cast iron, it has significant advantages.

[0052] The rotary motion of the honing head is realized by the main motion motor, the axial feed motion is realized by the feed motor through the ball screw pair, and the radial feed motion is manually adjusted. The honing head moves downwards, first passes through the ELID electrolytic electrode, and performs electrolytic sharpening on it. After the sharpening is completed, it continues to move downwards to enter the workpiece for honing operation, and reciprocating honing in this way until the workpiece meets certain technological requirements. Then stop the machine, use the in-position detection system on the machine tool to det...

Embodiment 2

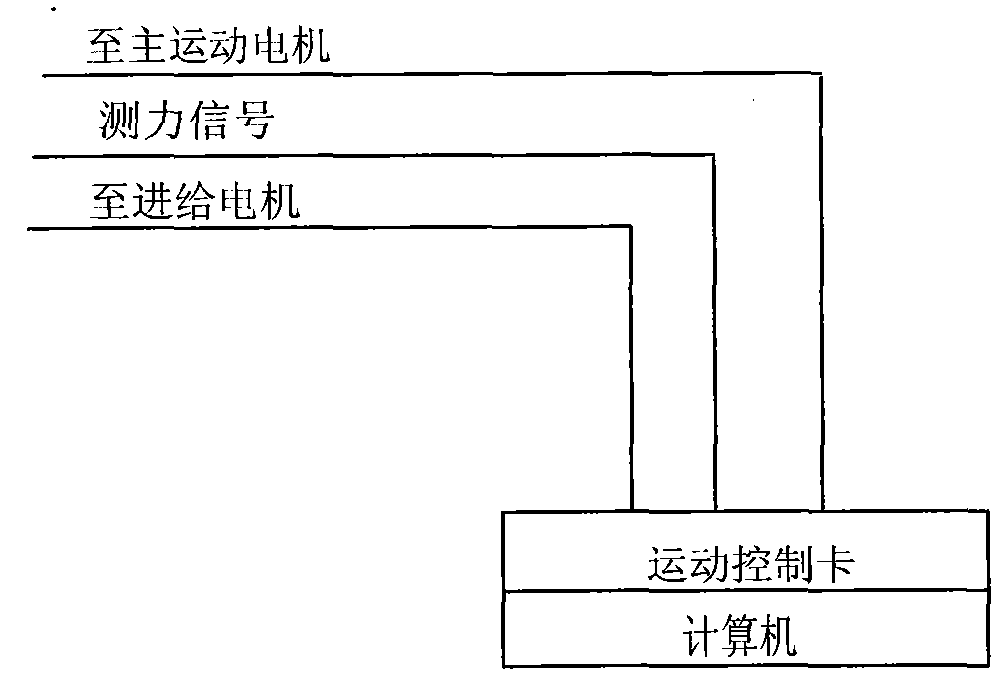

[0065] See attached figure 2 , the force measuring signal is used as the control variable. When the system monitors that the honing force exceeds the threshold value set in the system, it will automatically adjust the feed motor and spindle motor to achieve a reasonable match of honing parameters and ensure that there is always an oxide film on the surface of the honing stone. Covering, so that it can play an effective auxiliary polishing role. All the other are the same as embodiment one.

Embodiment 3

[0067] See attached image 3 , is made up of feed part and ultrasonic power supply, ELID power supply introduction part, ultrasonic vibration part, movable joint and spring part, honing tool part 39. The honing tool part 39 includes a transducer 37 , an expanding cone 35 and a whetstone 36 . The upper part is connected to the main shaft of the machine tool to realize power input. The ultrasonic vibration power supply and ELID power supply 38 are introduced through the carbon brush-collector ring 32. The joint part of the collector ring 32 and the hollow main shaft 33 is connected with an insulating sleeve. Introduce the power leads, where the ultrasonic power supply is connected to the terminal of the transducer 37, while the anode lead of the ELID power supply is connected to the push rod of the feeding part, through the push rod 34 to the expansion cone 35 to the oil stone seat and then to the oil stone 36 Complete the power anode access. The insulating sleeve is used at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com