Workbench structure for powder-spraying automobile wheel and powder-spraying method

A workbench and powder spraying technology, which is applied to coatings, devices for coating liquid on surfaces, etc., can solve the problems of high investment in manipulators, high capital investment, difficult maintenance, etc., and achieve the effect of saving manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

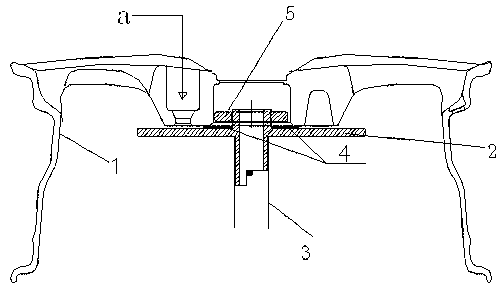

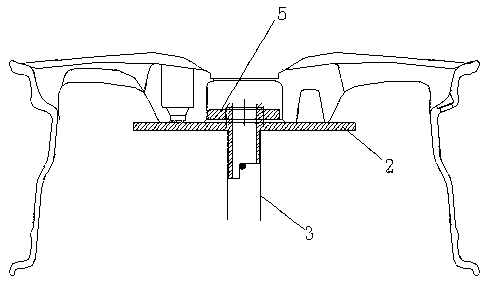

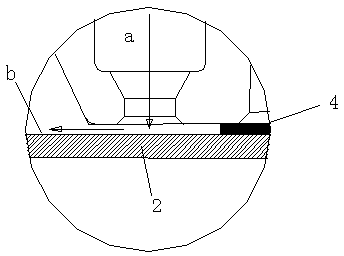

[0023] Such as figure 1 and figure 2 As shown, a method for protecting the assembly surface of a wheel after powder spraying, a support 3 is provided between the installation surface and the tray 2, and the installation surface and the tray 2 are separated by a height of 1-3 mm. The support 3 is designed Form a circular structure with three protruding end gaskets, made of stainless steel, with a thickness of about 1-3mm. After powder spraying, remove the bolt hole protective cover and the special cover for center hole protection, and blow the powder with a powder blowing device.

[0024] A support member 3 is set between the wheel mounting surface and the pallet 2. Generally, the wheel has at least four bolt holes, and all the bolt hole layout rules are evenly distributed on a concentric circle. The support member 3 is designed to have three bolt holes. An annular gasket structure with two protruding ends, the three protruding ends of the annular gasket are evenly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com