Treatment method for fluorine-containing waste gas

A technology of waste gas treatment and alkali method, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc. It can solve the problems that the daily fluoride monitoring compliance rate cannot be achieved, the fluoride removal rate cannot meet the requirements, and the pollutant discharge is difficult to meet the standards etc. to achieve the effect of light weight, high defogging efficiency and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

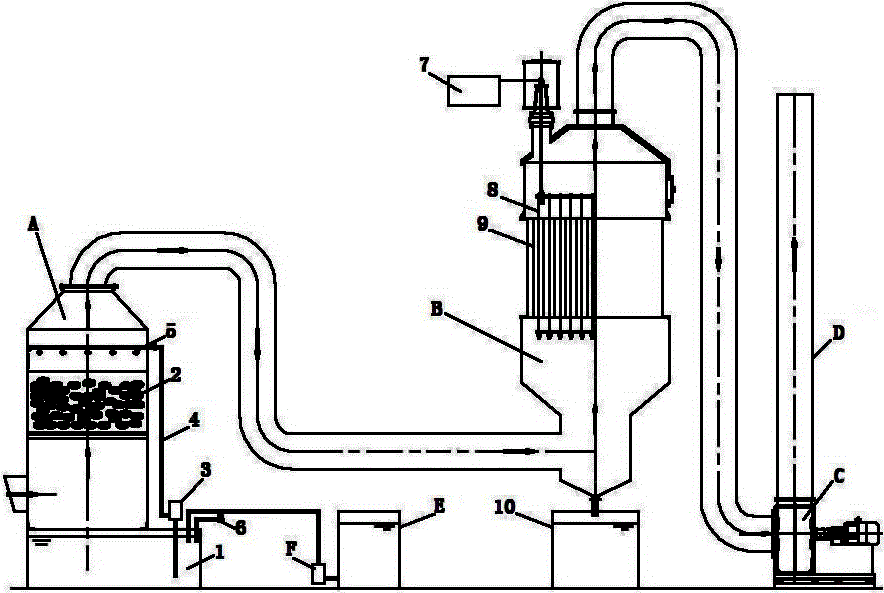

[0027] Example: such as figure 1 As shown, the fluorine-containing waste gas treatment device in this embodiment includes an alkaline absorption packing scrubber A, a conductive FRP electric demister B, a FRP centrifugal fan C, a FRP chimney D, a NaOH storage tank E and a NaOH pump F. Among them: Alkaline absorption packing washing tower A is equipped with circulating water tank 1, hollow filler 2, water pump 3, spray pipe 4, nozzle 5 and water pipe 6, water pump 3 is connected to circulating water tank 1 and spray pipe 4, and water pipe 6 is connected to the circulating water tank 1; the conductive FRP electric demister B is equipped with a high-voltage DC generator 7, a corona pole line 8, a FRP precipitation pole 9 and a waste liquid collection tank 10. Below the fogger B, the FRP chimney D is connected to the upper end of the conductive FRP electric demister B, the FRP centrifugal fan C is installed at the bottom of the FRP chimney D, and the NaOH pump F is connected to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com