Method for manufacturing chicken feed mixing machine

A manufacturing method and the technology of a mixer, which are applied in the field of equipment for raising chickens, can solve the problems of small mixing volume, time-consuming and laborious, and slow mixing speed, and achieve the effects of uniform mixing, convenient use, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

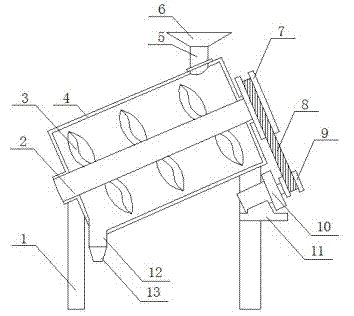

[0028] The present invention will be described below in conjunction with the accompanying drawings.

[0029] The manufacture method of chicken feed mixer of the present invention is as follows:

[0030] A. Weld the motor platform on the bracket, and fix the motor bolts on the motor platform;

[0031] B. Select a cylindrical steel pipe as the cylinder, and fix the cylinder on the bracket obliquely. The inclination angle between the cylinder and the ground is 50-70 degrees;

[0032] C. Open a hole in the upper part of one side of the cylinder as a hopper, and open a hole in the lower part of the other side of the cylinder as a discharge port;

[0033] D. Fix the stirring blades on the rotating shaft in layers, the number of layers is 3-5, install the rotating shaft into the cylinder, make one end of the rotating shaft pass through the cylinder, and install the turntable at this end, connect the turntable with the motor on the The output shafts are connected together with a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com