Earth leakage protection socket with functions of sparking prevention and reverse connection protection

A protection function and leakage protection technology, which is applied to the parts, circuits, connections, etc. of the connection device, can solve the problems of too many and too dense components on the circuit board, long movement tracks, and easy strain of devices, so as to save assembly time , Simplify the assembly process and save the mold cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

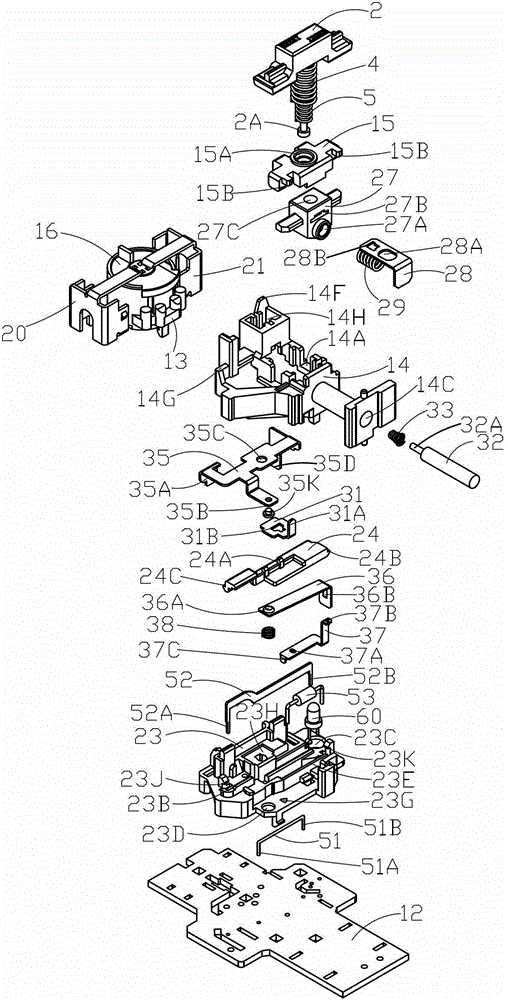

[0072] refer to Figure 16 to Figure 21 The difference between this embodiment and Embodiment 1 lies in the arrangement of three pairs of metal sheets: a pair of metal sheets that pass through the double induction coils (L1, L2) and are connected to the circuit board 12 are extended from the power input terminals (20, 21) On the circuit board 12, a pair of elastic metal sheets (17, 18) that are connected between the fixed end and the metal sheet extending from the power input end are drawn out, and the free ends of the elastic metal sheets (17, 18) can follow the release 27 for lifting movement , the free end of the elastic metal sheet (17, 18) has two pairs of contacts; the output conductor (8, 9) extends a pair of static metal sheets, and the end of the output conductor static metal sheet has a free elastic metal sheet drawn from the power input end The contacts (8A, 9A) above the terminal; the power supply output terminal (80, 81) is extended with a pair of static metal she...

Embodiment 3

[0075] refer to Figure 22 to Figure 28 , in this embodiment, the power input ends (21, 20) are extended with a pair of metal sheets passing through the double induction coils (L1, L2) and the ends are connected to the circuit board 12, and the metal sheets (17, 18 ) and the metal sheets (19, 25) drawn out from the power supply output end are drawn out through flexible wires and fixed on the release 27; two pairs of output conductors (8, 9) lead out from the power supply input end and the power supply output end. Contacts (8B, 8A, 9B, 9A) on the static metal sheets corresponding to the top and bottom of the sheet, in order to ensure good contact, two pairs of static metal sheets are provided with contacts (17A, 18A) that are in contact with the metal sheets (17, 18) Contacts (8B, 9B) that are in contact with the metal sheets (19, 25), when the reset button guide column is hooked with the lock catch 28 and positioned, the metal sheets drawn from the power input end and the powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com