Method for testing crystal by X-ray diffraction

An X-ray and crystal technology, applied in the field of lattice mismatch material testing, can solve the problems of low work efficiency, time-consuming reciprocal space map scanning, researchers can not use RSM measurement, etc., to achieve the effect of improving the test speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1 is used for the test of a plurality of samples of the same kind produced in the same batch. The growth parameters of each sample are close and the structure is the same.

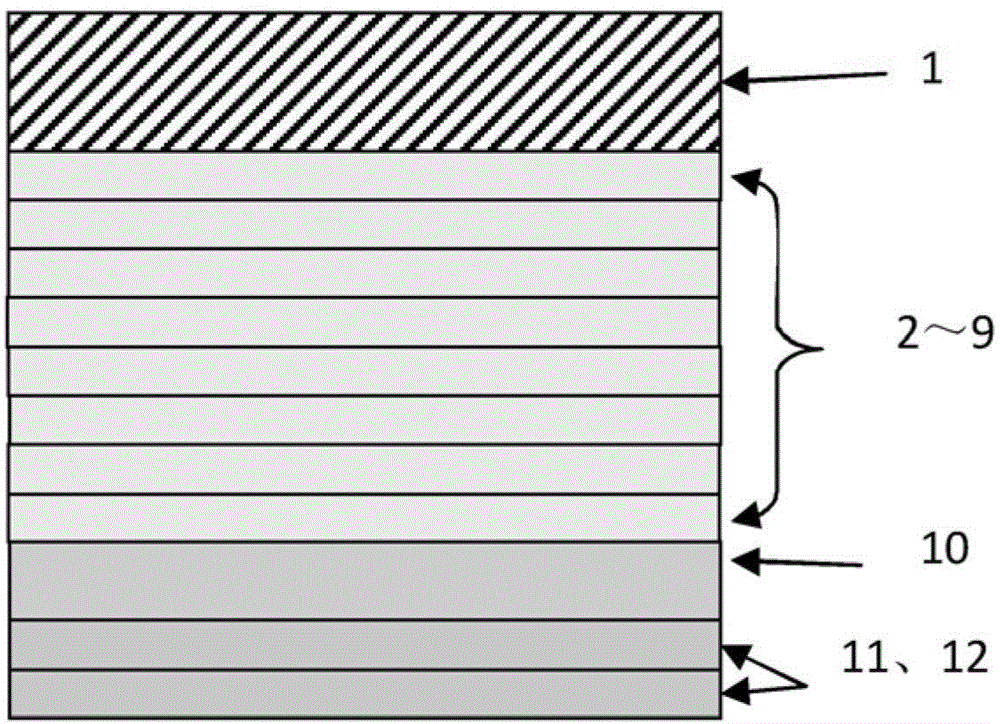

[0042] figure 1A structural diagram of a sample according to an exemplary embodiment is shown. The sample includes a single crystal substrate 1, transition layers 2-9 grown sequentially on the single crystal substrate 1, a large mismatch material (with a large difference in lattice constant from the substrate) 10 grown on the transition layer 9, and Two layers of lattice fully strained material 11 and 12 grown on large mismatch material 10 .

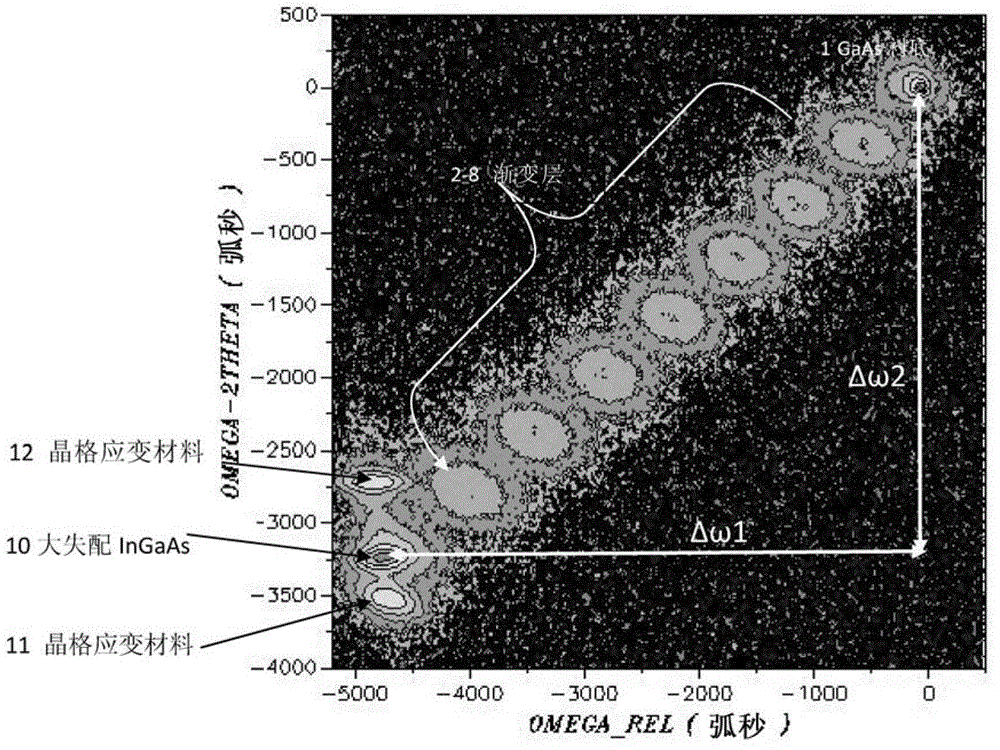

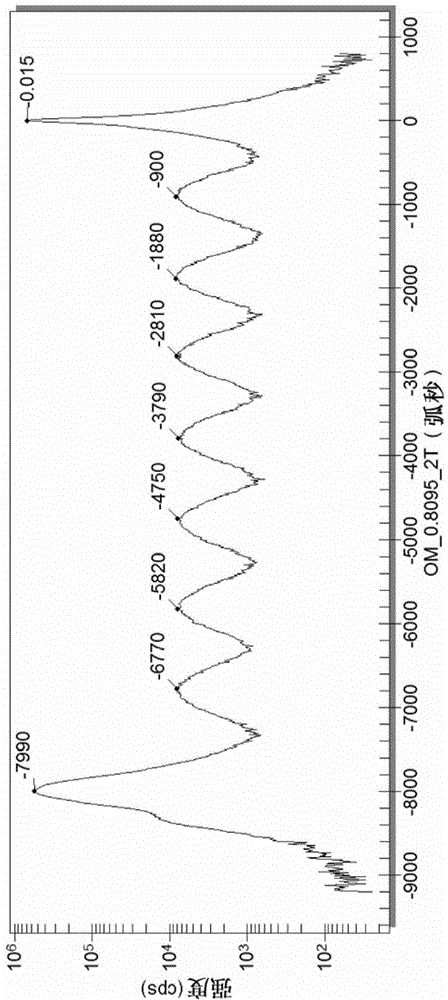

[0043] The single crystal substrate 1 is a 4-inch GaAs single wafer, the direction of the crystal plane (100) and the monotectic plane (111) are 7 degrees, and the orientation side is the crystal plane Eight layers of InGaAlAs transition layers 2-9 are grown on the substrate 1 by means of MOCVD (Metal Organic Vapor Phase Chemical Deposition). T...

Embodiment 2

[0092] The sample structure of Example 2 is similar to that of Example 1. The test method of embodiment 2 is basically the same as that of embodiment 1, the difference is that it uses a rough RSM scan and a 1:n ω-2θ scan to test the sample for the same sample, and it is applied to different growth parameters. Sample-by-sample testing. The specific test process is as follows:

[0093] 1. For the sample to be tested, first roughly scan the RSM diagram of the (004) isosymmetric plane with a large step length (150 arc seconds), and the scanning interval is the same as in Example 1, that is, the ω_rel coordinate axis: -5200~500 arc seconds, ω-2θ coordinate axis: -4000~500 arc seconds. Then the (004) symmetry plane scan takes about 25 minutes. According to the RSM diagram obtained by rough scanning, the motion relationship 1:n of ω and 2θ was calculated in the same manner as in Example 1.

[0094] According to this embodiment, the range of the step size of the coarse scan can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com