High-low temperature dynamic cold-hot circulation thermodynamic test system

A technology of cold and heat cycle and test system, which is applied in the direction of applying stable tension/pressure to test the strength of materials, scientific instruments, measuring devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

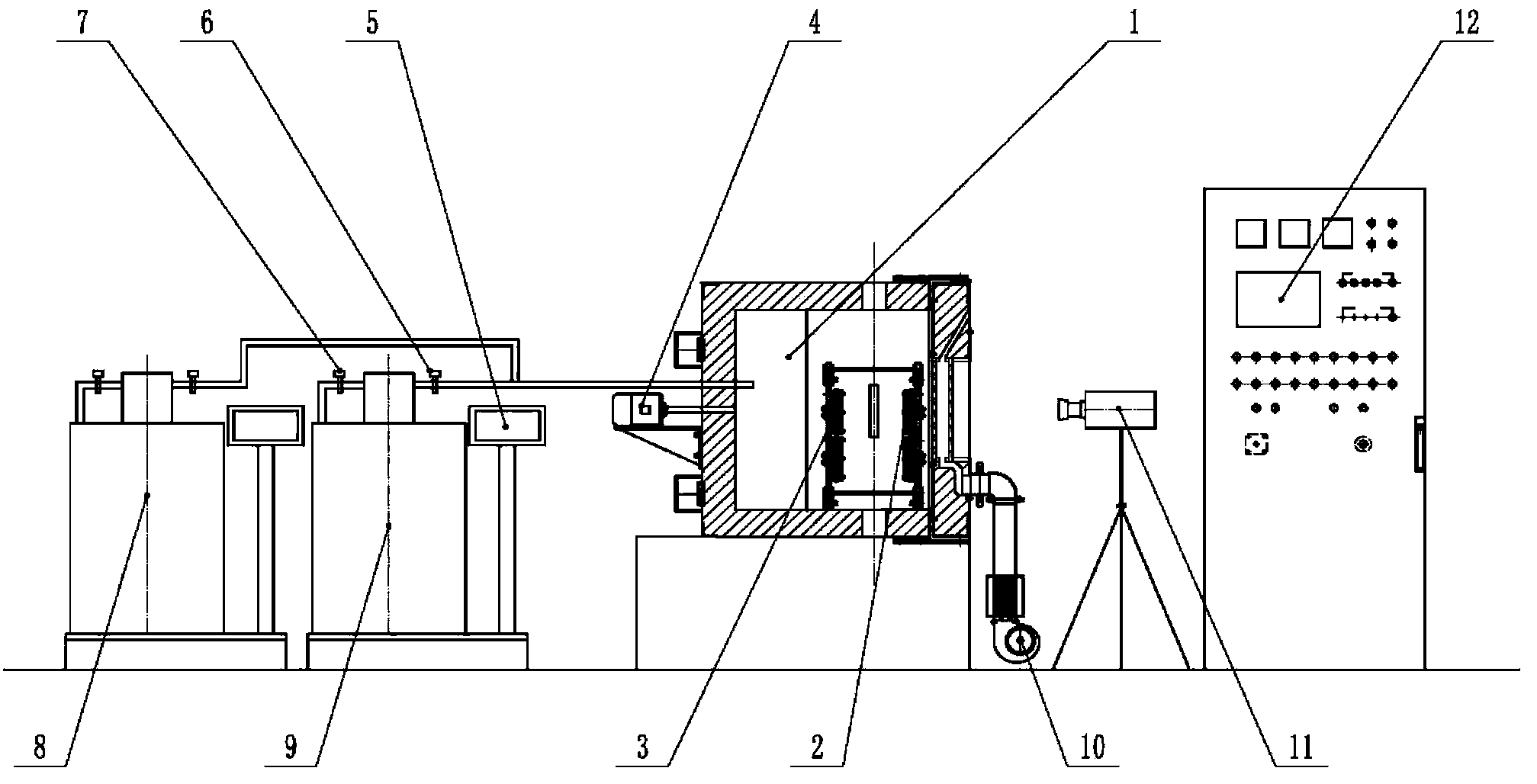

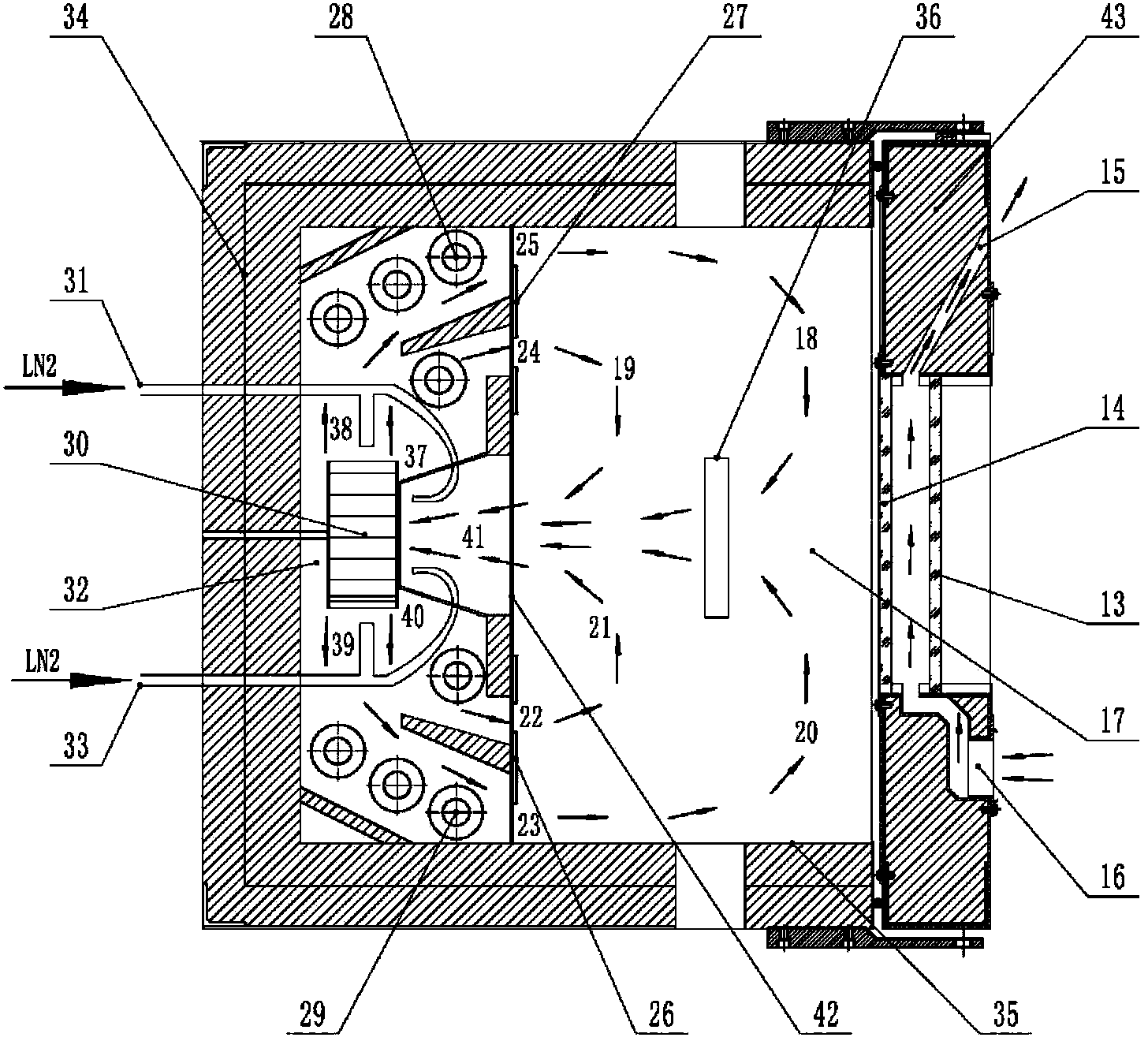

[0014] The structure, principle and specific implementation of the present invention will be further clearly and completely described below in conjunction with the accompanying drawings. figure 1 It is a schematic diagram of the overall structure of the high and low temperature dynamic cooling and heating cycle thermodynamics test system. The system includes a test chamber 1, a lighting system in the chamber, a liquid nitrogen refrigeration system, an observation window and a system control cabinet. The test chamber 1 is divided into an inner chamber by an inner and outer partition The body 32 and the outer cavity 17, the inner cavity 32 contains heating wires and wind-stirring turbines, and the separator is provided with an air outlet and an air suction port; the test system also includes a dual-output PID controller and a DIC full-field strain measuring instrument; The liquid nitrogen refrigeration system described above adopts a self-switching liquid nitrogen refrigeration s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com