Open type communication and heat-absorption heat exchanger with headers and double-channel cold water pipes and manufacturing process for heat exchanger

The invention relates to a cold water pipe and open type technology, which is applied in the field of open-end connected heat-absorbing heat exchangers with double-channel cold water pipes in the header, which can solve the problems of poor heat absorption effect, low heat exchange efficiency, and inability to pour acid liquid, etc. Achieve the effect of reducing manufacturing and labor costs, increasing heat exchange surface area, and facilitating cleaning of fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

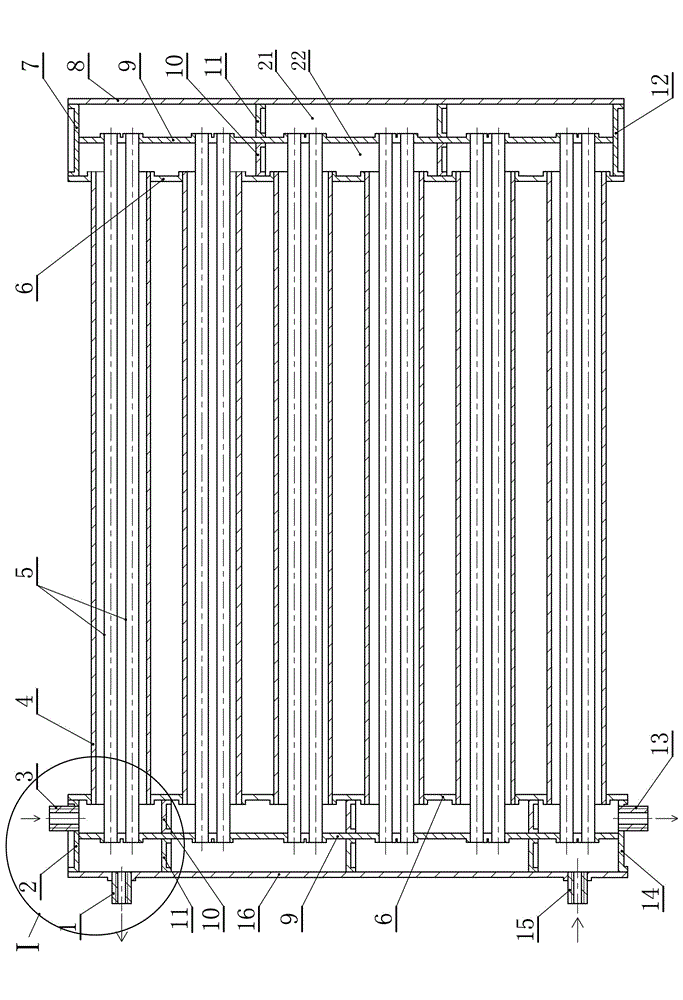

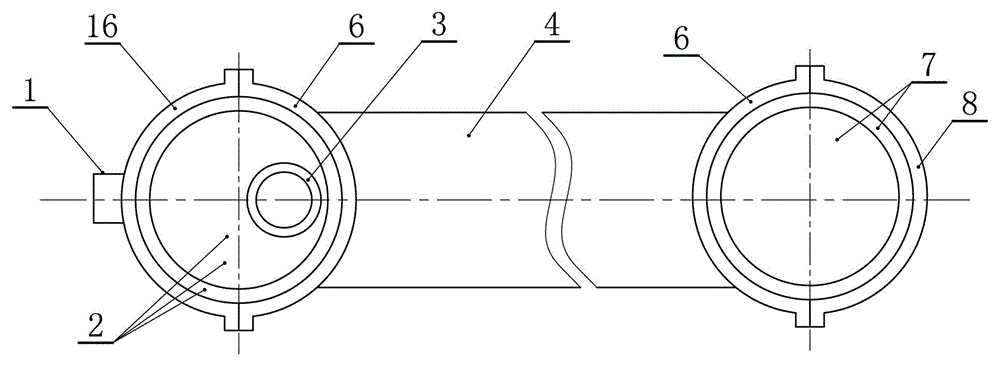

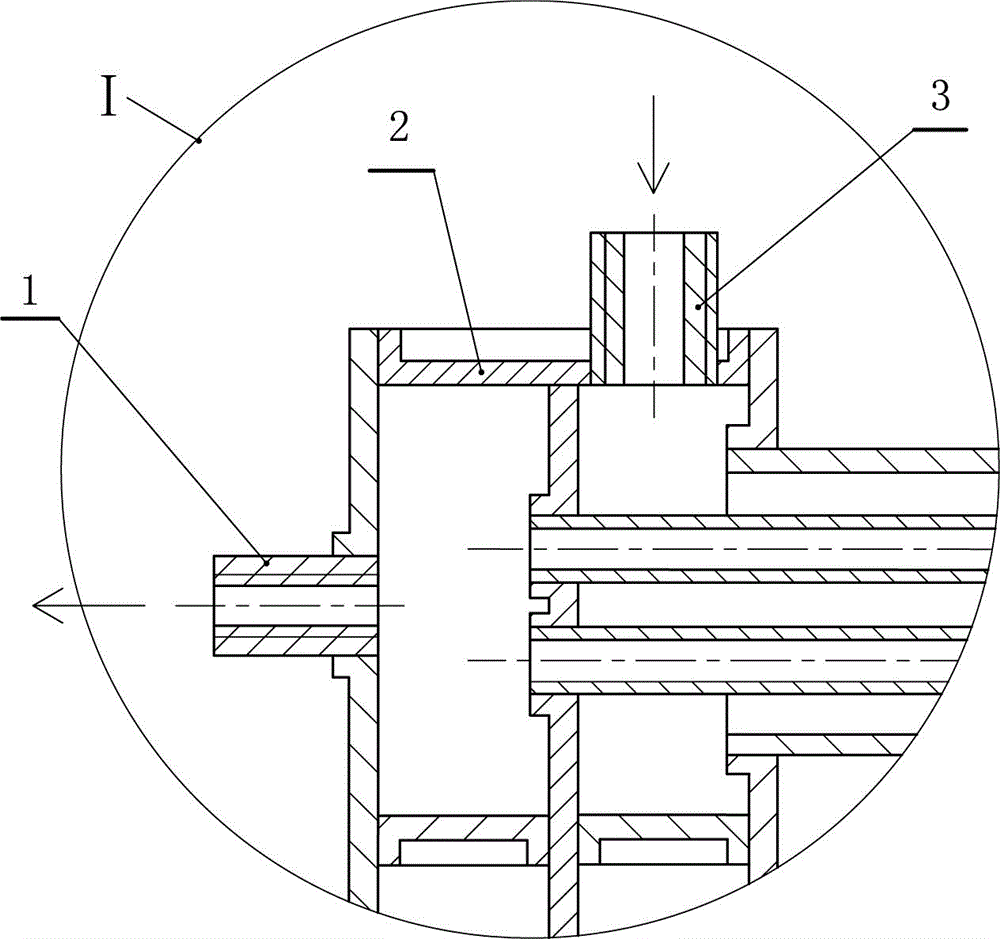

[0079]A header double-channel cold water pipe open-ended connected heat-absorbing heat exchanger, the orifice plate of the header is connected to two or more heat supply pipes, and the two ends of the heat supply pipes are respectively welded with C-shaped or groove-shaped inner half headers Orifice plate; the heat supply pipe and the orifice plate of the C-shaped or trough-shaped inner half header are welded and connected to form a radiator-shaped shell; the orifice plate of the C-shaped or trough-shaped inner half header; plate; the porous middle plate is stamped with connecting holes; the heating pipe and the cavity of the inner half header are interspersed with cold water pipes; the two ports of the cold water pipe are connected with the open cavity of the hole wall of the porous middle plate, Plate, heat supply pipe, perforated middle plate and end cover plate constitute the hot fluid cavity channel. The hot fluid circular tube or rectangular tube-shaped double-row channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com