Finishing solution and preparation method thereof

A skin-pass liquid and liquid technology, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as rusting of the crankshaft, affecting the cleaning of the working environment, overflowing of the work foam of the skin-passing machine, etc., and achieves reduced contact parts and good lubrication Effect, the effect of good anti-rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

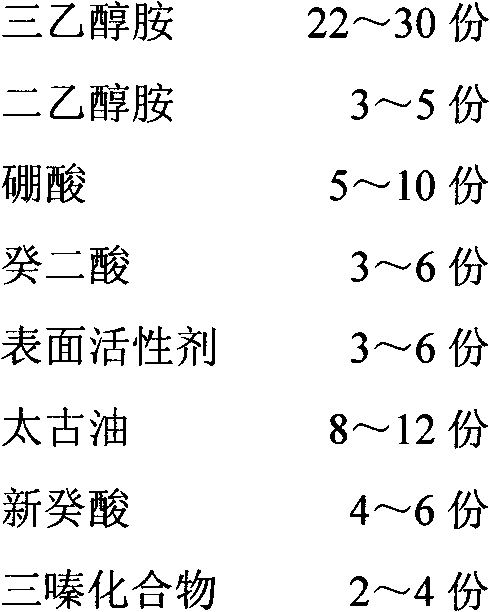

[0027] A smoothing solution of the present invention is composed of the following components by weight:

[0028]

[0029] The preparation method of a kind of smoothing liquid of the present invention, its steps are as follows:

[0030] a) Put 22 parts of triethanolamine and 3 parts of diethanolamine into the reactor and heat up to about 60°C;

[0031] b) Add 7 parts of boric acid and 4 parts of sebacic acid, stir for about 40 minutes while adding, and raise the temperature to about 100°C, so that the liquid becomes completely clear and transparent;

[0032] c) Add 43.5 parts of water, 6 parts of surfactant, 8 parts of ancient oil, 3 parts of neodecanoic acid, 3 parts of triazine compound, and 0.5 part of emulsified silicone oil in proportion, and stir until the solution is clear It can be made into a smoothing liquid when it is transparent.

[0033] The finishing liquid made of this component has good cleaning performance, low cost, slightly poor rust resistance and sligh...

Embodiment 2

[0035] A smoothing solution of the present invention is composed of the following components by weight:

[0036]

[0037]

[0038] The preparation method of a kind of smoothing liquid of the present invention, its steps are as follows:

[0039] a) Put 30 parts of triethanolamine and 5 parts of diethanolamine into the reactor and heat up to about 60°C;

[0040] b) Add 8 parts of boric acid and 6 parts of sebacic acid, stir for about 40 minutes while adding, and raise the temperature to about 100°C, so that the liquid becomes completely clear and transparent;

[0041] c) Add 25.5 parts of water, 4 parts of surfactant, 12 parts of Swire oil, 5 parts of neodecanoic acid, 4 parts of triazine compound, and 0.5 part of emulsified silicone oil in proportion, and stir until the solution is clear It can be made into a smoothing liquid when it is transparent.

[0042] The finishing liquid made of this component has good rust resistance and good lubricity, but the cost is relative...

Embodiment 3

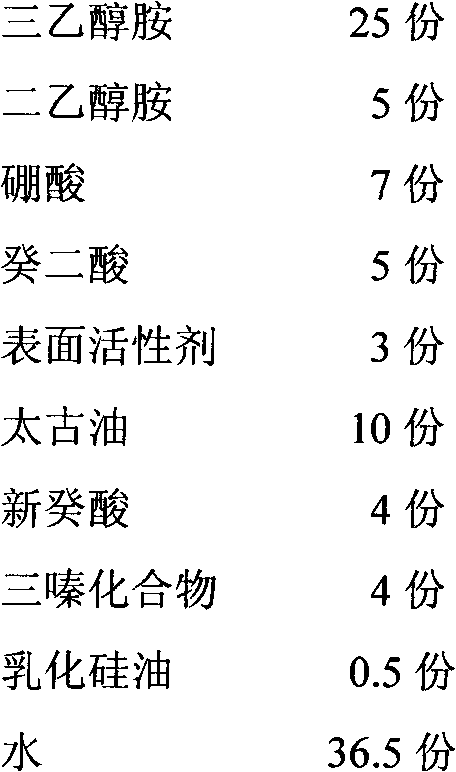

[0044] A smoothing solution of the present invention is composed of the following components by weight:

[0045]

[0046] The preparation method of a kind of smoothing liquid of the present invention, its steps are as follows:

[0047] a) Put 25 parts of triethanolamine and 5 parts of diethanolamine into the reactor and heat up to about 60°C;

[0048] b) Add 7 parts of boric acid and 5 parts of sebacic acid, stir for about 40 minutes while adding, and raise the temperature to about 100°C, so that the liquid becomes completely clear and transparent;

[0049] c) Add 36.5 parts of water, 3 parts of surfactant, 10 parts of Swire oil, 4 parts of neodecanoic acid, 4 parts of triazine compound, and 0.5 part of emulsified silicone oil in proportion, and stir until the solution is clear It can be made into a smoothing liquid when it is transparent.

[0050] The finishing fluid made from this component has good rust resistance, lubricity, cleaning performance, anti-corruption abili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com