Hydrotreatment and catalytic cracking combined method of heavy hydrocarbon raw material

A catalytic cracking and combined method technology, used in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problem that the downflow fixed bed reaction activity cannot be fully exerted, the operation period and reaction temperature do not match, and the operation period is prolonged. problems, to achieve the effect of improving logistics distribution, reducing viscosity, and inhibiting coke formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

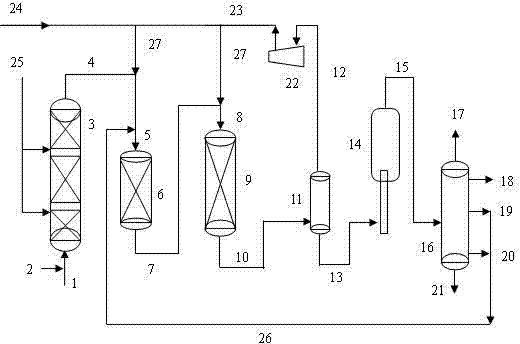

[0040] In this embodiment, a process flow of one UFR reactor and two downflow fixed-bed reactors is set, and the two downflow fixed-bed reactors are located downstream of the UFR and used in series with the UFR. The oil produced by hydrogenation in the downflow fixed bed reactor is used as the feed for catalytic cracking, and further hydrocracking reaction is carried out. The part of the catalytic cracking diesel oil is returned to the downflow fixed bed-reverse inlet, mixed with the effluent of the UFR reactor, and reacted through the downflow fixed bed reactors in turn.

[0041] The raw material used is a typical Middle East residual oil, the catalyst used is FZC-10U type upflow hydrogenation catalyst, the reaction temperature is 387°C, the total reaction pressure is 15.7MPa, the volume space velocity: 0.50h -1 , under the process condition of hydrogen oil specific volume (V / V) 230, the hydrogenation upgrading reaction is carried out in the upflow residual oil hydrogenation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com