Continuous melting furnace for producing quartz glass bar and manufacture technology

A quartz glass rod, continuous melting furnace technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problems of limited application scope, inability to produce high-quality products, inability to produce high-end quartz tube rods, etc. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

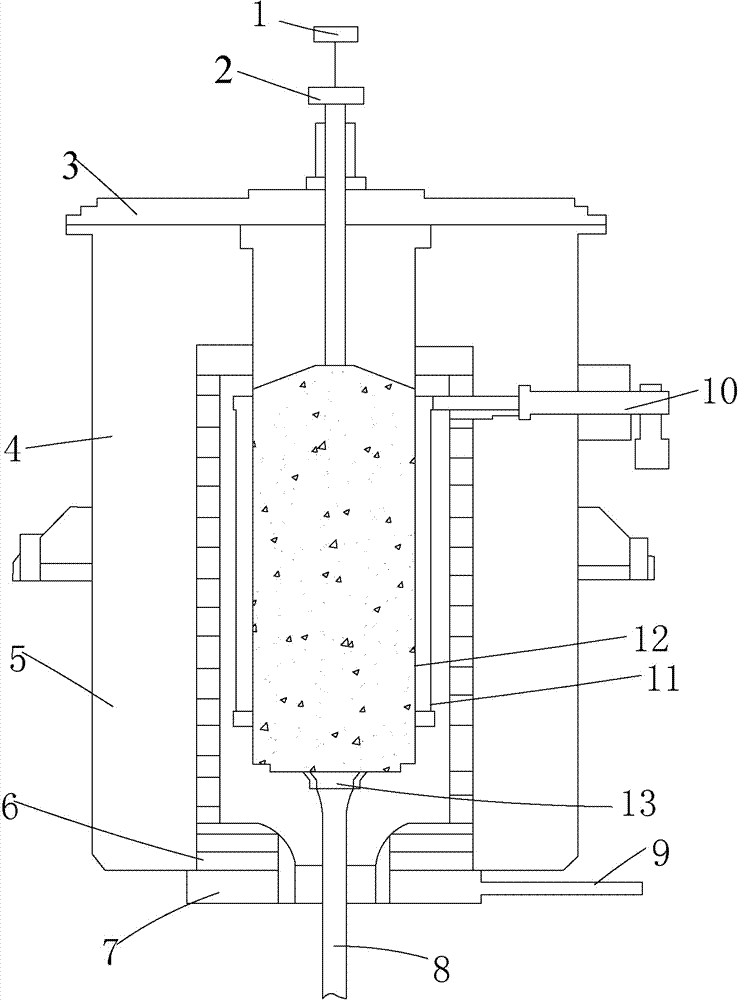

[0013] Such as figure 1 As shown, it is a continuous melting furnace for producing quartz glass rods in the present invention, including a furnace body 4 and a furnace cover 3 that cooperate with each other. A tungsten crucible 12 is arranged in the furnace body 4, and a heating net 11 connected to an electrode 10 is arranged on the outside of the tungsten crucible 12 and heat insulating sand 5, a high-temperature brick 6 is provided at the furnace mouth, a water jacket 7, a dust removal device 9, a feeding device 1 and a heat insulation device 2 are connected to the upper end of the tungsten crucible 12, and a forming device 13 is connected to the lower end of the tungsten crucible. Compared with the prior art, the core rod device is eliminated in the continuous melting furnace, and the high-purity quartz sand is directly injected into the tungsten crucible 12 and drawn into shape by the forming device 13 .

[0014] Use the present invention to produce the continuous melting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com