Automatic cutter conveying device of horizontal type broaching machine

A knife feeding and automatic technology, applied in the field of broaching machines, can solve the problems of low clamping accuracy, heavy broaching and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further illustrated in a non-limiting manner below in conjunction with the accompanying drawings and examples.

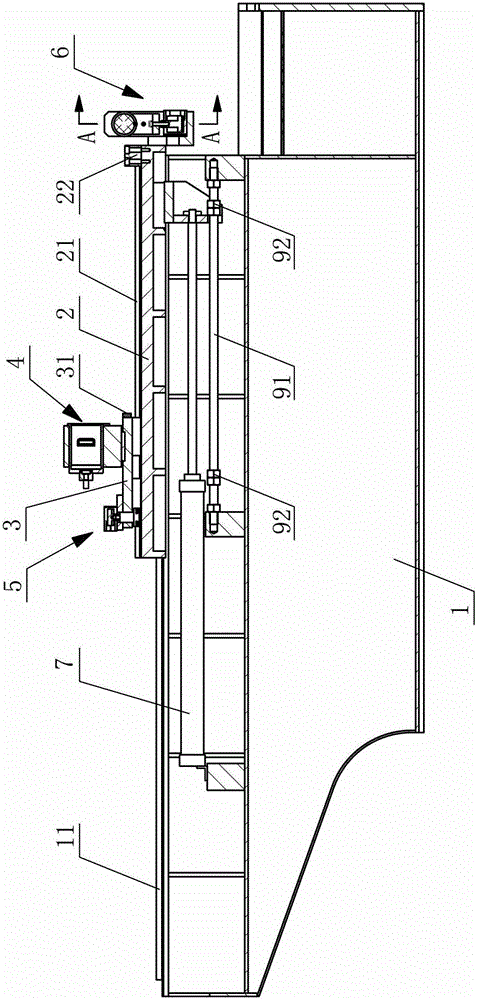

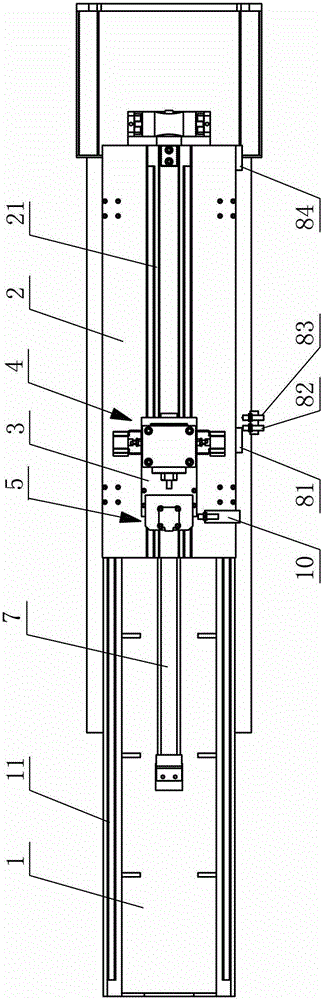

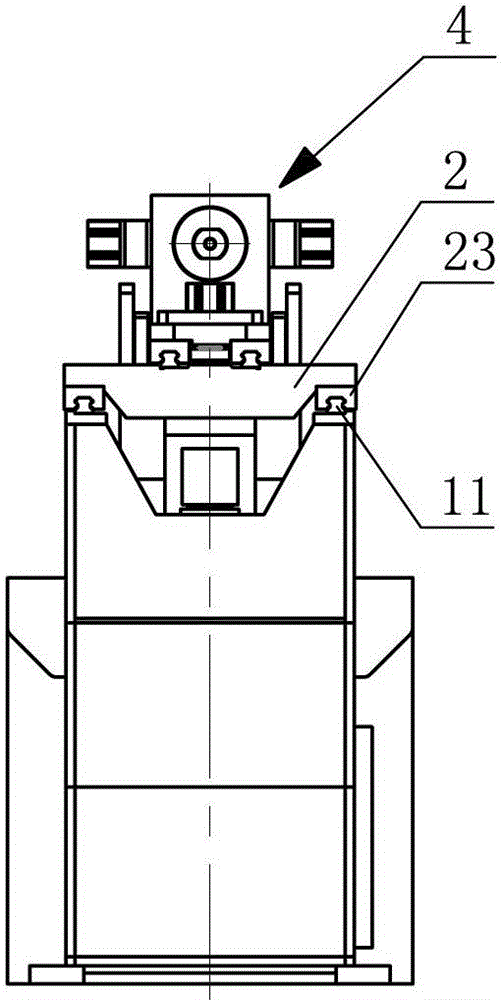

[0029] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the automatic knife feeding device of the horizontal broaching machine according to the embodiment of the present invention comprises: a base 1 on which a first linear guide rail 11 is horizontally arranged; a main slide 2 driven by a power unit The slider 23 passing through its bottom can reciprocate and linearly move along the first linear guide rail 11. The second linear guide rail 21 in the same direction as the first linear guide rail 11 is arranged on the main slide plate 2. At the end of the main slide plate 2 The part is provided with a lift supporting knife device 6; the knife sending slide plate 3 is slidably arranged on the second linear guide rail 21, and the broach automatic clamping device 4 and the knife feeding slide plate 3 are fixed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com