Precision numerical control processing method for thin-wall aluminium plate partially provided with through holes

A technology of precision numerical control and processing methods, applied in metal processing equipment, manufacturing tools, milling machine equipment details, etc., can solve problems such as poor processing stability, weak strength, and affecting the dimensional accuracy and smoothness of processed workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

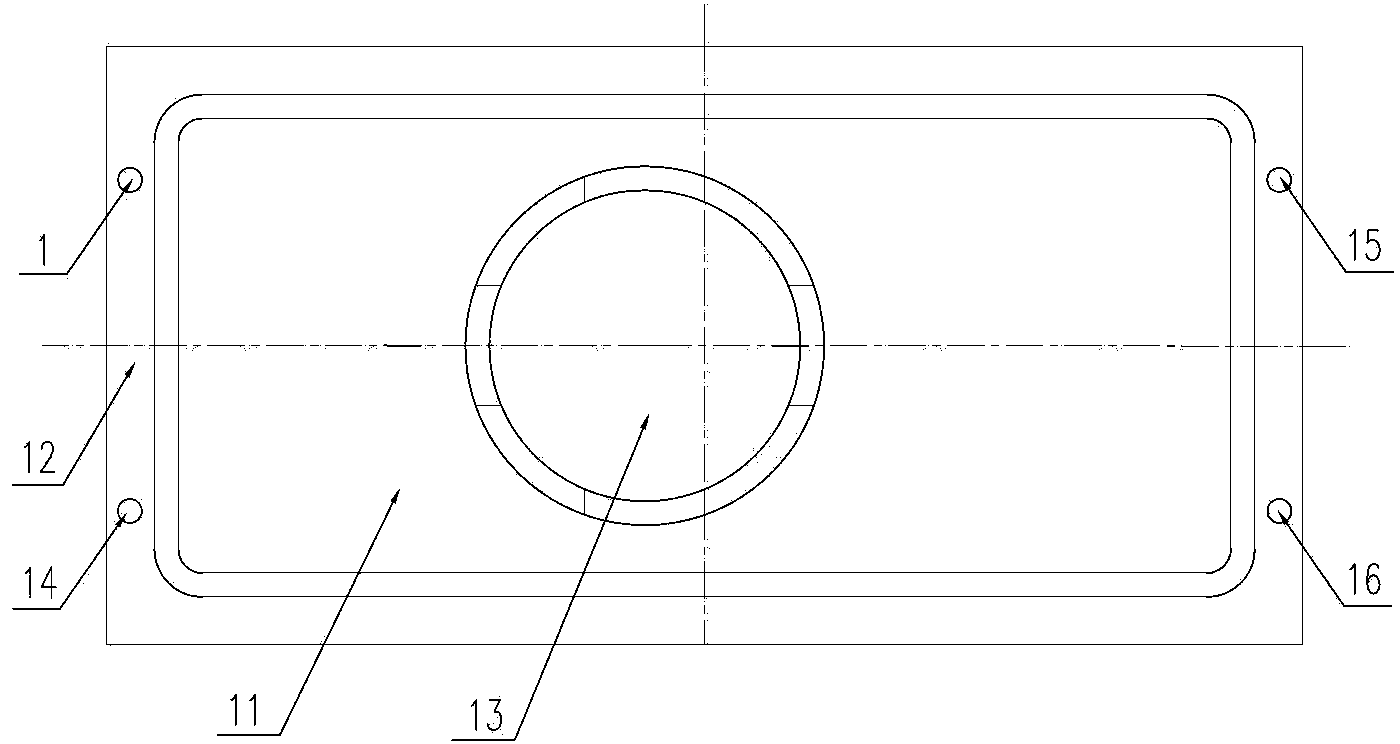

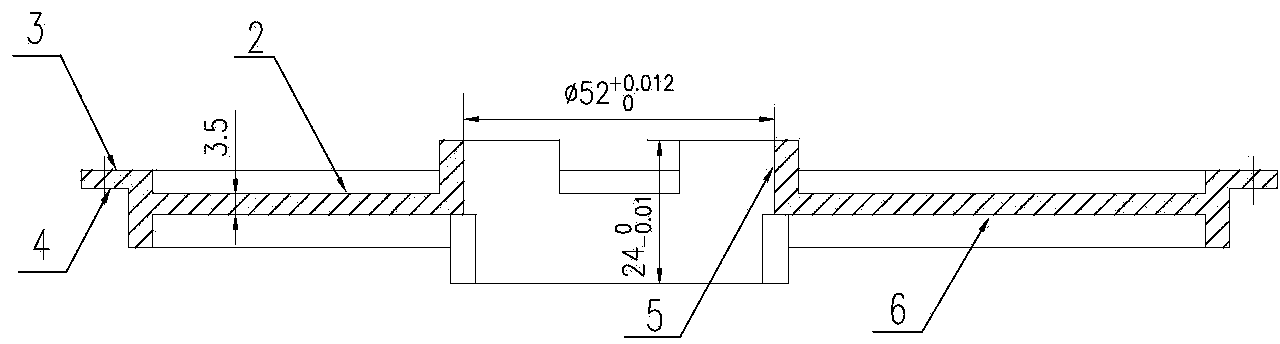

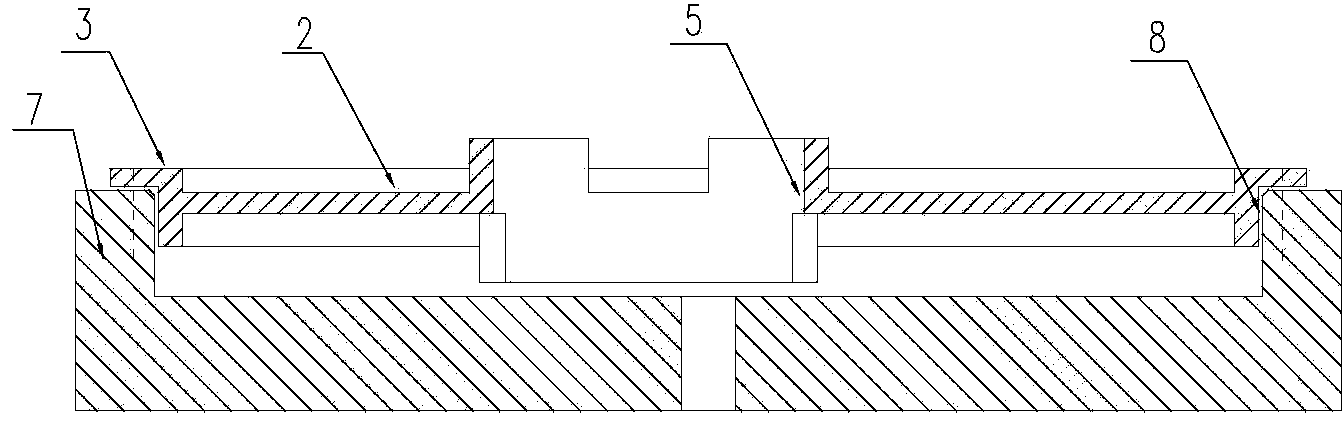

[0027] The length of the thin-walled aluminum part is 200mm, the width is 100mm, the roughness of the cylindrical surface in the through hole is Ra=0.8μm, the diameter of the through hole is 52mm, and the thickness of the thinnest part of the workpiece is 3.5mm. Schematic diagram of workpiece and clamping Figure 1-Figure 4 As shown, the workpiece includes a body 11 , a rim 12 and a through hole 13 . Its processing method comprises the following steps:

[0028] (1) Rough processing:

[0029] When roughing the front face, clamp the blank with vise, select an end mill with a diameter of 10mm, a cutting depth of 0.3mm, a feed rate of 2500mm / min, and a spindle speed of 3000rpm. For the processing surface without precision requirements, that is, the concave surface 2 of the workpiece is directly milled to size, and for the processing surface with precision requirements, that is, the bottom surface of the workpiece 3 and the cylindrical surface 5 in the through hole have a unilate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com